Precise color mixture driving control system and method of LED lamp

A technology of LED lamps and drive control, which is applied in energy-saving control technology, lamp circuit layout, light source, etc. It can solve problems such as color mixing deviation, failure to meet the needs of the stage and theater, and inconsistent parameters, so as to achieve reliable operation, automatic adjustment of lamp temperature, and operation Stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

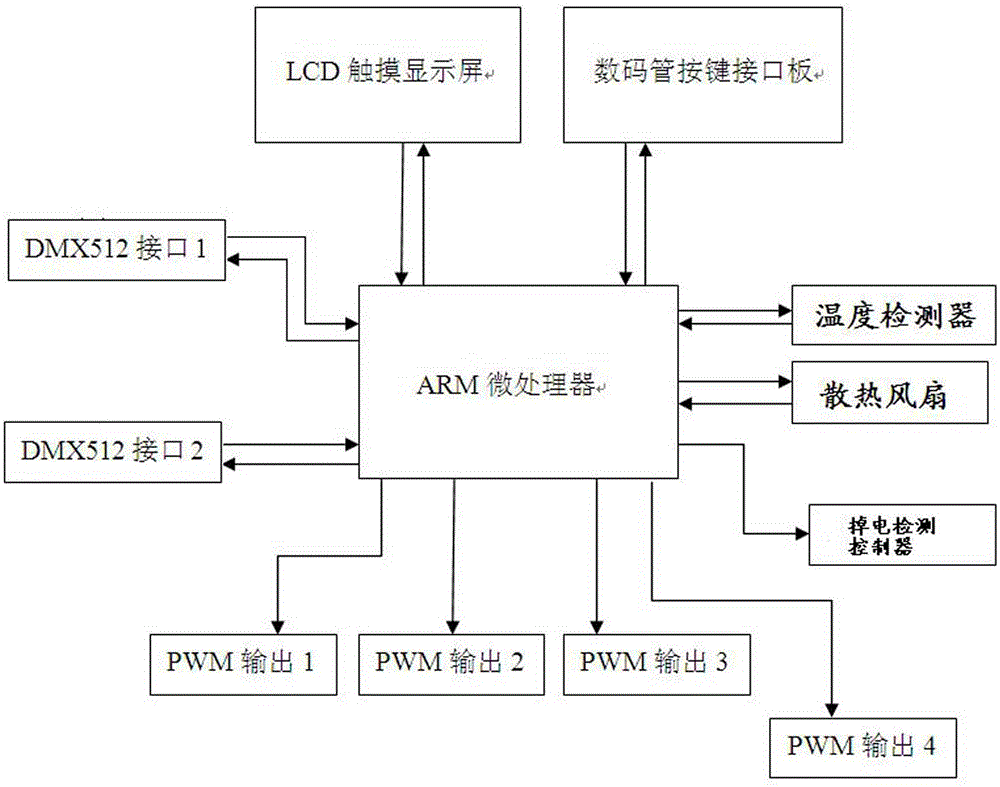

Embodiment 1

[0042] The substrate temperature of each LED lamp is detected in real time by the temperature detector, and the received temperature information is sent to the LCD touch screen for display. The operator checks the display screen and compares the detected temperature information with the preset temperature information. When the detected temperature value is greater than the preset temperature value, the operator sends an operation instruction to the controller according to the operation table on the LCD touch screen display, and the control The device performs complex algorithm processing according to the operation instructions and sends a color-mixing control command to the corresponding LED lamp. The LED lamp changes the light-emitting state according to the color-mixing control command to achieve the purpose of color mixing to protect the LED from damage and prolong its service life. At the same time, a rotation control command is sent to the cooling fan, and the cooling fan ...

Embodiment 2

[0044]The substrate temperature of each LED lamp is detected in real time by the temperature detector, and the received temperature information is sent to the digital tube button interface board for display. The operator checks the display screen and compares the detected temperature information with the preset temperature information. When the detected temperature value is greater than the preset temperature value, the operator sends an operation instruction to the controller according to the operation table on the digital tube button interface board. The controller performs complex algorithm processing according to the operation instructions and then sends a color mixing control command to the corresponding LED lamps. The LED lamps change the light-emitting state according to the color mixing control commands to achieve the purpose of color mixing to protect the LED from damage and prolong its service life. At the same time, a rotation control command is sent to the cooling f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com