Passivated lithium metal-carbon skeleton composite material and preparation method and application thereof

A carbon composite material, metal lithium technology, applied in the fields of material science and new energy science, can solve the problems of electrolyte burning, danger, overheating, etc., and achieve the inhibition of lithium dendrite formation, good cycle stability, and high Coulomb efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] In some embodiments, the preparation method may further include: uniformly mixing molten lithium metal with a porous carbon material carrier, and cooling to obtain a lithium metal-skeleton carbon composite material. Wherein, after heating and melting metallic lithium (preferably with a purity of more than 99.99%), the carbon framework material will absorb it into the pores of the carbon framework material. Similarly, low-melting-point metals such as sodium, potassium, and tin can also be absorbed into the carbon material skeleton according to this.

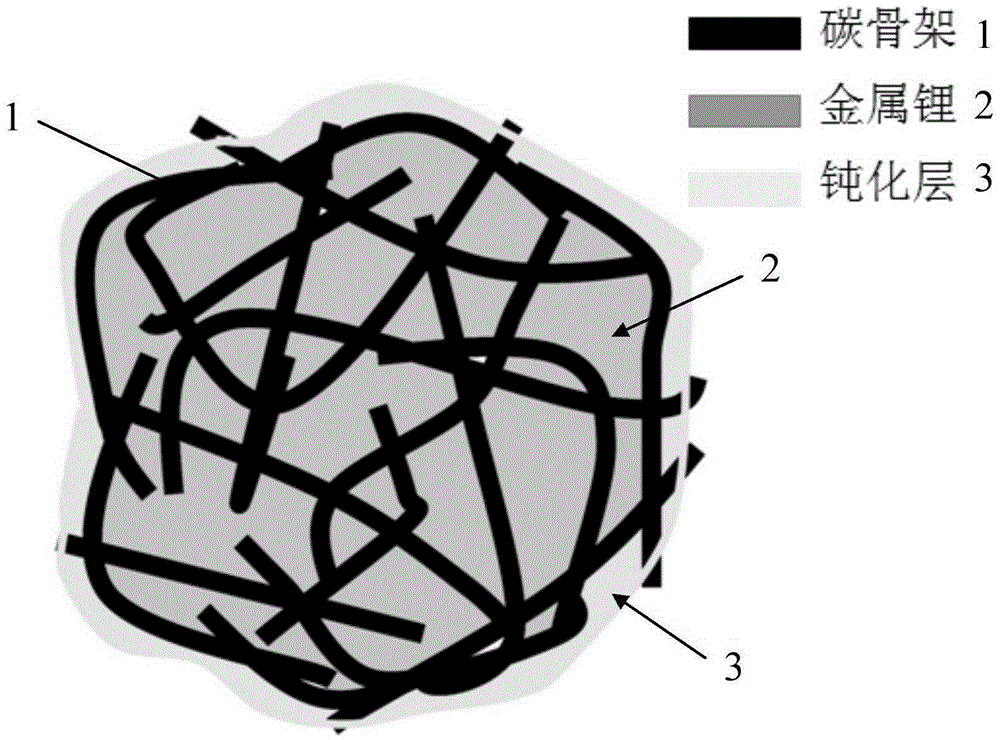

[0051] Correspondingly, in some embodiments, a passivated metal-skeleton carbon composite material is also provided, which includes:

[0052] A metal-skeleton carbon composite material comprising a porous carbon material support and metal particles distributed at least in the pores of the porous carbon material support; and,

[0053] The passivation layer is at least used to prevent the metal particles in the metal-skeleto...

Embodiment 1

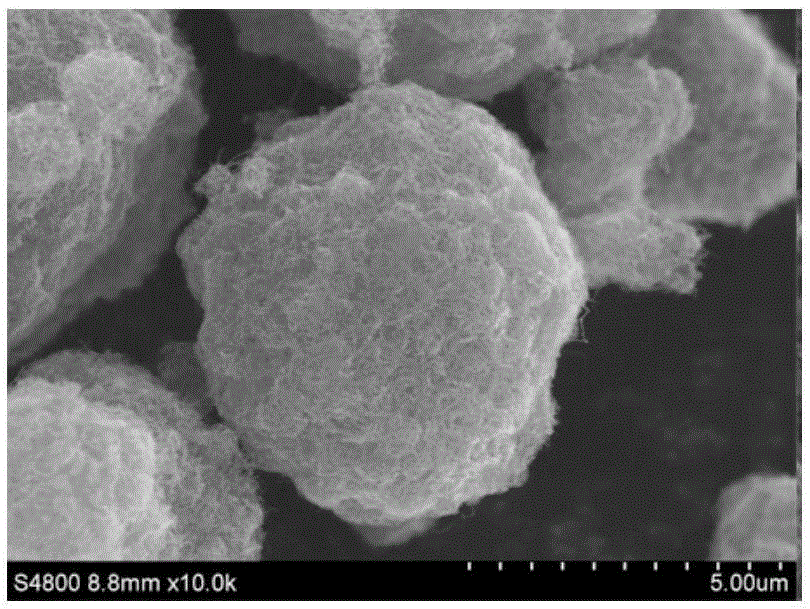

[0078] Embodiment 1: Preparation of metal lithium-carbon nanotube particle composite material:

[0079] Preparation of carbon nanotube microspheres: first, add 4 g of multi-walled carbon nanotubes without any chemical treatment to 200 ml of deionized water, and then add 20 mL of absolute ethanol. Sealed and stirred, 130W ultrasonic probe ultrasonic treatment for 10h, so that the sample is evenly dispersed. When finished, add the sample to the spray dryer. The inlet air temperature was set at 200°C, the outlet air temperature was set at 150°C, the spray pressure was set at 40MPa, the injection volume was set at 500mL / h, and the carbon nanotube microsphere material was obtained after drying. Nitrogen adsorption and desorption tests were carried out on the microspheres, and the specific surface area of the microspheres was 254m 2 / g, the average pore diameter is 31.4nm.

[0080] Lithium metal-carbon nanotube particle composite material First weigh 200mg battery-grade lithium...

Embodiment 2

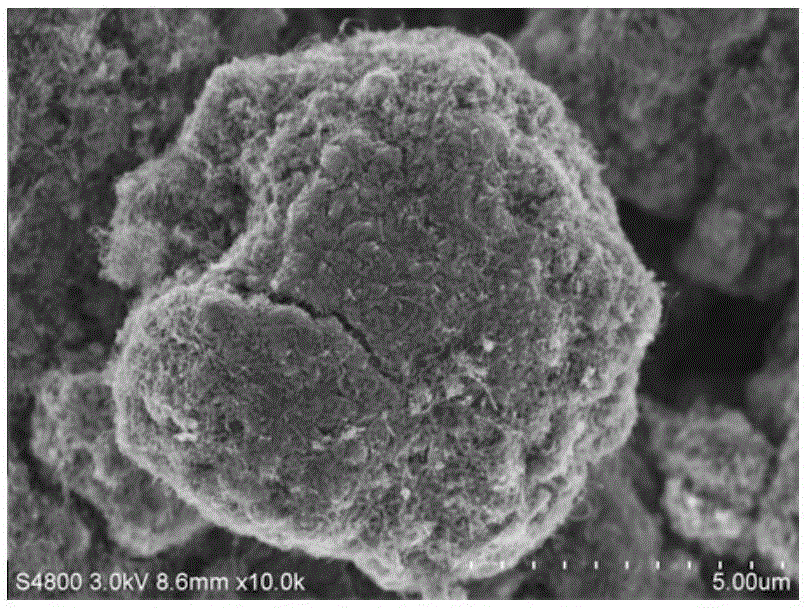

[0082] Embodiment 2: Preparation of metal lithium-carbon nanotube particle composite material treated with sulfur passivation:

[0083] First, configure a certain concentration of sulfur-containing organic solvent. In this implementation case, configure a n-hexane solution with a sulfur content of 0.001mol / L, and weigh 200 mg of the lithium metal-carbon nanometer prepared in Example 1 in the glove box. The tube microspheres were mixed with 3ml of sulfur-containing solution, stirred for about 2 hours, then suction-filtered, and washed with a solvent for several times to obtain a metal lithium-carbon nanotube particle composite material treated with sulfur passivation.

[0084] Figure 2b It is a scanning electron micrograph of metal lithium-carbon framework material and metal lithium-carbon nanotube particle composite material after passivation. From Figure 2b It can be seen that after passivation, the morphology of metal lithium-carbon nanotube particle composites has not c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com