A kind of manufacturing method of n-type bifacial battery

A technology of double-sided battery and manufacturing method, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of expensive ion implantation equipment, high production cost, and large damage to silicon wafers, so as to reduce the diffusion "dead layer" and reduce damage and pollution, and the effect of improving battery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

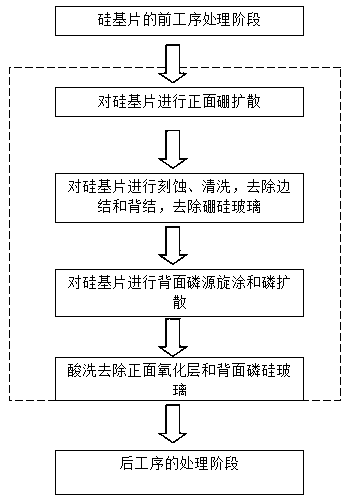

[0034] A method for manufacturing an N-type double-sided battery, including performing pre-processing on an N-type single crystal silicon substrate, performing boron diffusion on the surface of the silicon substrate, performing wet etching on the silicon substrate and cleaning borosilicate glass, Diffusion of phosphorus on the back of the silicon substrate, cleaning of the silicon substrate to remove phosphorus silicon glass, growth of passivation layer and deposition of anti-reflection layer on the front and back of the silicon substrate, preparation of positive and negative electrodes of the battery, and completion of N-type double-sided The production of the battery; the specific steps are as follows:

[0035] (1) Perform pre-process treatment on the N-type monocrystalline silicon substrate: take an N-type monocrystalline silicon substrate with a resistivity of 1Ω·cm, and clean the surface of the silicon substrate with a mixed solution of hydrogen peroxide and sodium hydroxi...

Embodiment 2

[0044] A method for manufacturing an N-type double-sided battery, including performing pre-processing on an N-type single crystal silicon substrate, performing boron diffusion on the surface of the silicon substrate, performing wet etching on the silicon substrate and cleaning borosilicate glass, Diffusion of phosphorus on the back of the silicon substrate, cleaning of the silicon substrate to remove phosphorus silicon glass, growth of passivation layer and deposition of anti-reflection layer on the front and back of the silicon substrate, preparation of positive and negative electrodes of the battery, and completion of N-type double-sided The production of the battery; the specific steps are as follows:

[0045] (1) Pre-processing the N-type monocrystalline silicon substrate: take an N-type monocrystalline silicon substrate with a resistivity of 1.5Ω·cm, and clean the surface of the silicon substrate with a mixed solution of hydrogen peroxide and sodium hydroxide; then Using ...

Embodiment 3

[0054] A method for manufacturing an N-type double-sided battery, including performing pre-processing on an N-type single crystal silicon substrate, performing boron diffusion on the surface of the silicon substrate, performing wet etching on the silicon substrate and cleaning borosilicate glass, Diffusion of phosphorus on the back of the silicon substrate, cleaning of the silicon substrate to remove phosphorus silicon glass, growth of passivation layer and deposition of anti-reflection layer on the front and back of the silicon substrate, preparation of positive and negative electrodes of the battery, and completion of N-type double-sided The production of the battery; the specific steps are as follows:

[0055] (1) Perform pre-process treatment on the N-type monocrystalline silicon substrate: take an N-type monocrystalline silicon substrate with a resistivity of 2Ω·cm, and clean the surface of the silicon substrate with a mixed solution of hydrogen peroxide and sodium hydroxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com