Intelligent three-phase oil-immerse power distribution transformer

A distribution transformer, oil-immersed technology, applied in the field of transformers, can solve the problems of complex mechanism, high sealing performance requirements, difficult to achieve, etc., and achieve the effect of increasing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

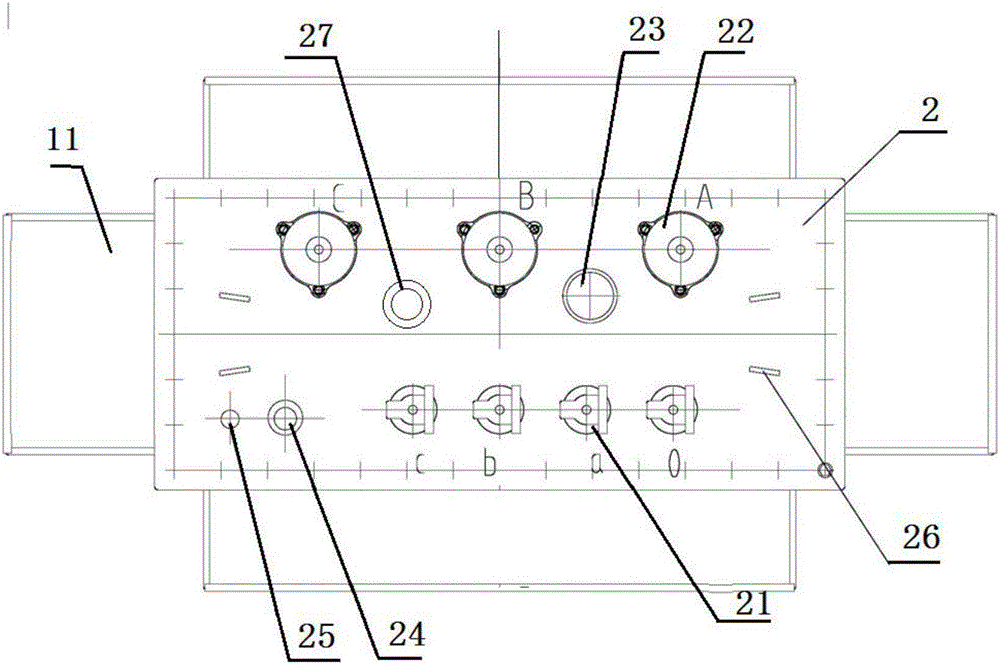

[0030] Figure 1 to Figure 4 It schematically shows an intelligent three-phase oil-immersed distribution transformer according to the first embodiment of the present invention.

[0031] Such as figure 1 As shown, the present invention discloses an intelligent three-phase oil-immersed distribution transformer, including an oil tank 1, which is equipped with a transformer core, and at the same time, the oil tank 1 is filled with high-temperature resistant insulating oil. In this embodiment of the present invention, The high-temperature resistant insulating oil is β liquid, and silicone oil FR3 natural ester can also be used in practical applications. The transformer core is immersed in high temperature resistant insulating oil.

[0032] Such as Figure 1 to Figure 4 As shown, preferably, in this embodiment of the present invention, the oil tank 1 adopts a corrugated oil tank, such as image 3 As shown, the oil tank 1 is a hollow cuboid cavity 10 with an upper opening, and th...

Embodiment 2

[0041] Figure 1 to Figure 6 It schematically shows that an intelligent three-phase oil-immersed distribution transformer is provided according to the second embodiment of the present invention.

[0042] Such as Figure 1 to Figure 4 As shown, the second embodiment of the present invention discloses an intelligent three-phase oil-immersed distribution transformer which is basically the same as that of Embodiment 1, except that:

[0043] Such as figure 2 , image 3 , Figure 5 and Figure 6 As shown, as another invention point of the present invention, in this embodiment of the present invention, a control system for controlling the fuel tank in the fuel tank 1 is included, the control system includes a liquid level sensor 28 fixed on the inner wall of the fuel tank 1, and A controller 27 above the cover 2, and the liquid level sensor 28 is connected with the controller 27. Such as figure 2 As shown, the liquid level sensor 28 is fixed on the upper end of one side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com