Side channel compressor having a seal assembly

A technology of sealing components and side channels, which is applied to the sealing of engines, pump components, mechanical equipment, etc., can solve the problems of reduced efficiency level, wear of sealing components, satisfactory sealing effect of sealing components, etc., and achieve the effect of reliable function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

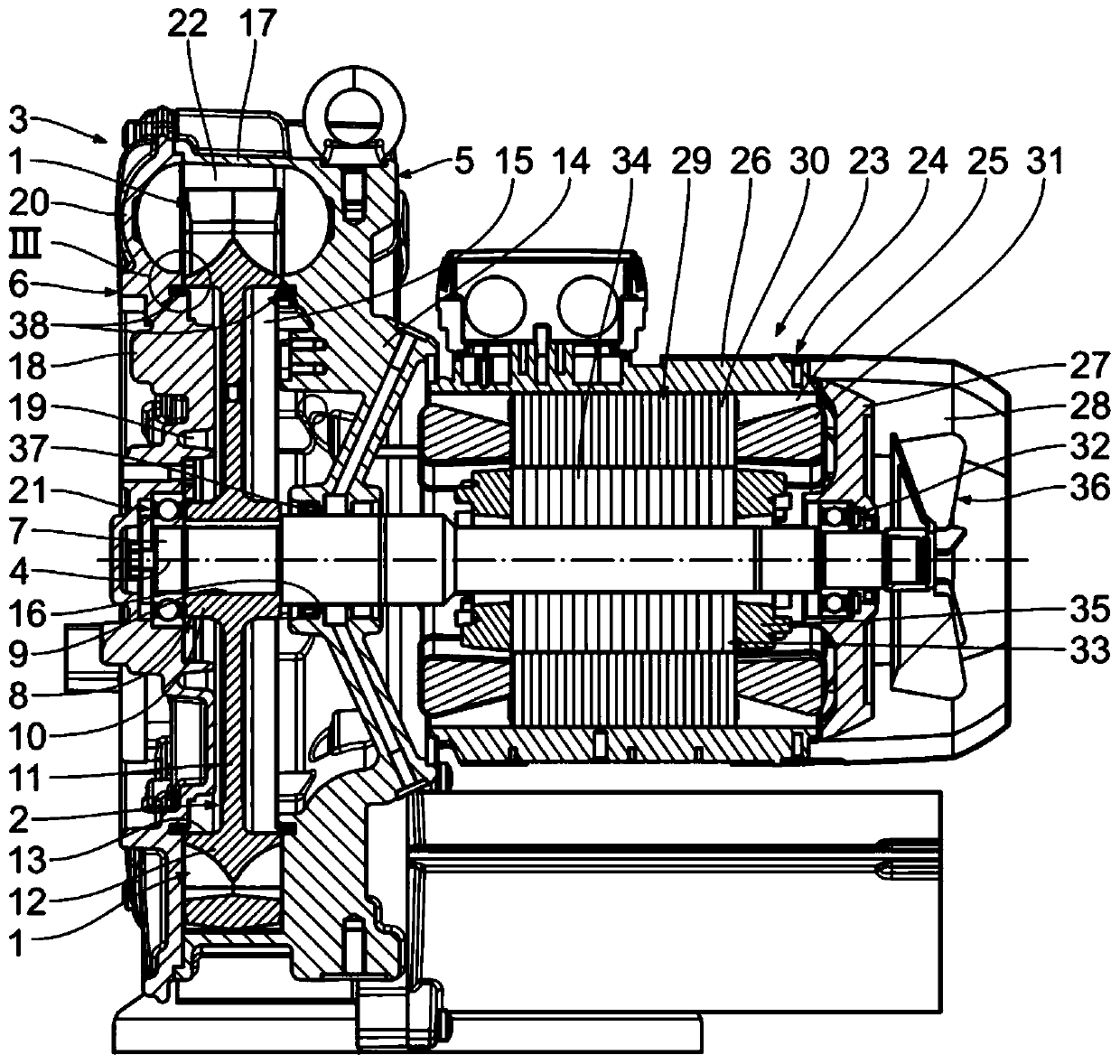

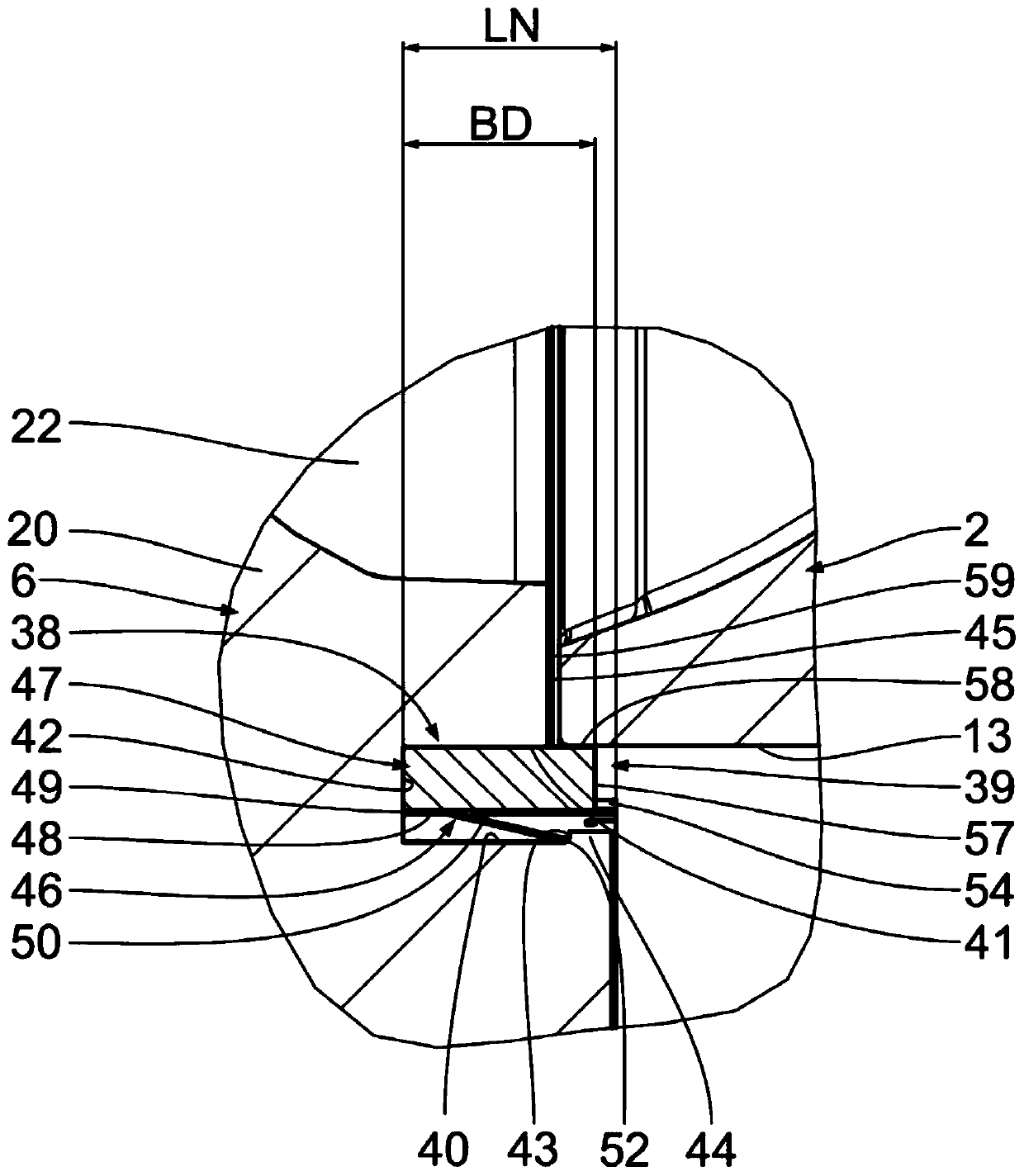

[0038] First, refer to figure 1 ,exist figure 1 shows generally an assembled side channel compressor for compressing a gas, comprising an impeller 2 provided with impeller blades 1 and mounted so that it can be positioned sideways about a longitudinal central axis 4 The rotary drive is carried out in the casing 3 of the channel compressor. Thus, the longitudinal center axis 4 forms an axis of rotation.

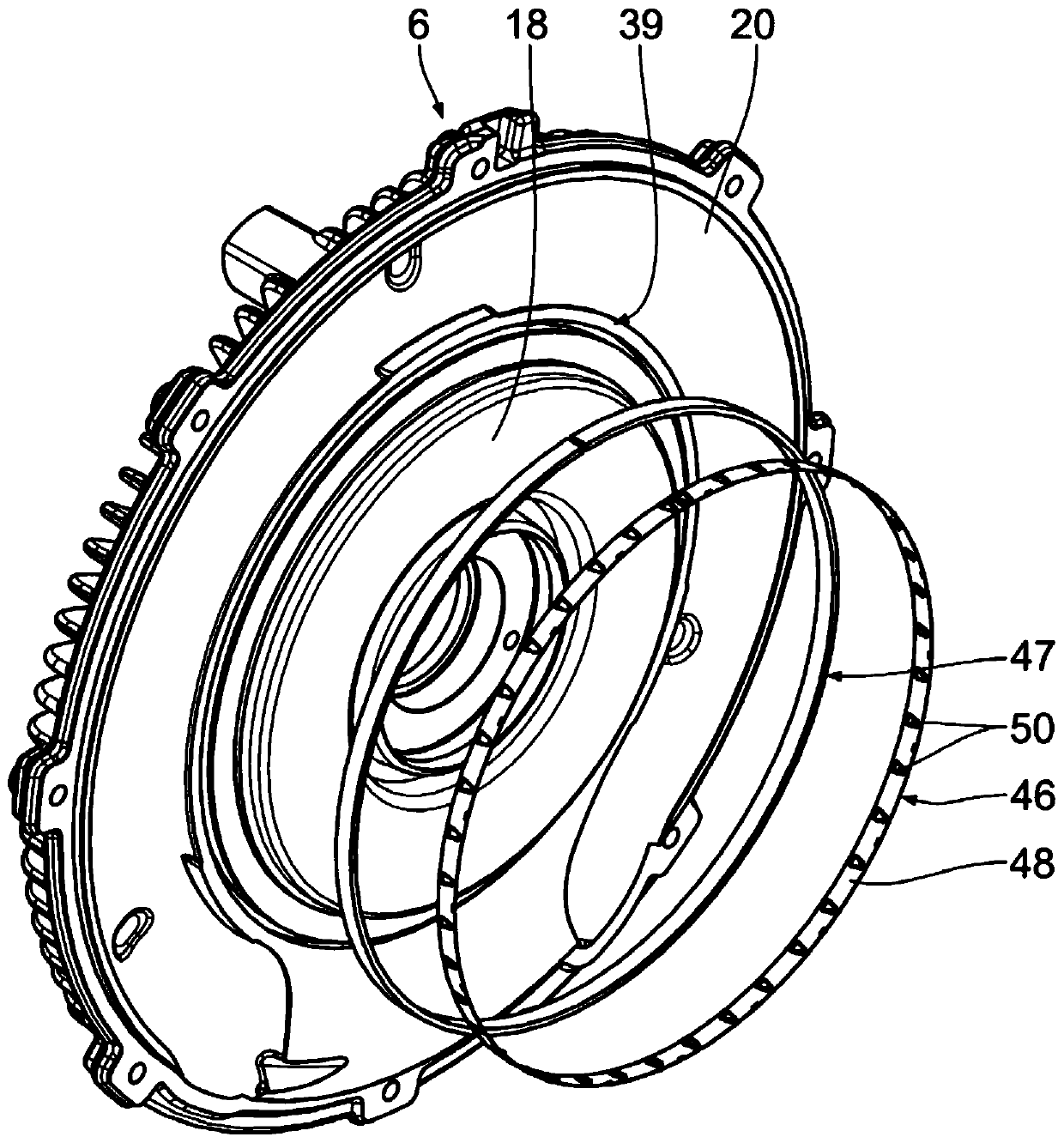

[0039] The case 3 has a housing 5 and a removable case cover 6, according to figure 1 , the casing 5 and the removable casing cover 6 are aligned together and together surround the impeller 2 , which is arranged in a rotationally fixed manner on the drive shaft 7 and has the impeller blades 1 .

[0040] The single-row impeller 2 is configured in the manner of a disk. The single-row impeller 2 has an impeller hub 8 with a central hub bore 9 . The impeller hub 8 is formed by an inner hub foot 10 adjoining the hub bore 9 radially outwards and an annular hub 11 adjoining said...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com