Executor of elastic element for volume balance

An actuator and elastic technology, applied in the direction of belts/chains/gears, mechanical equipment, transmission devices, etc., can solve problems such as insecurity, and achieve the effect of simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

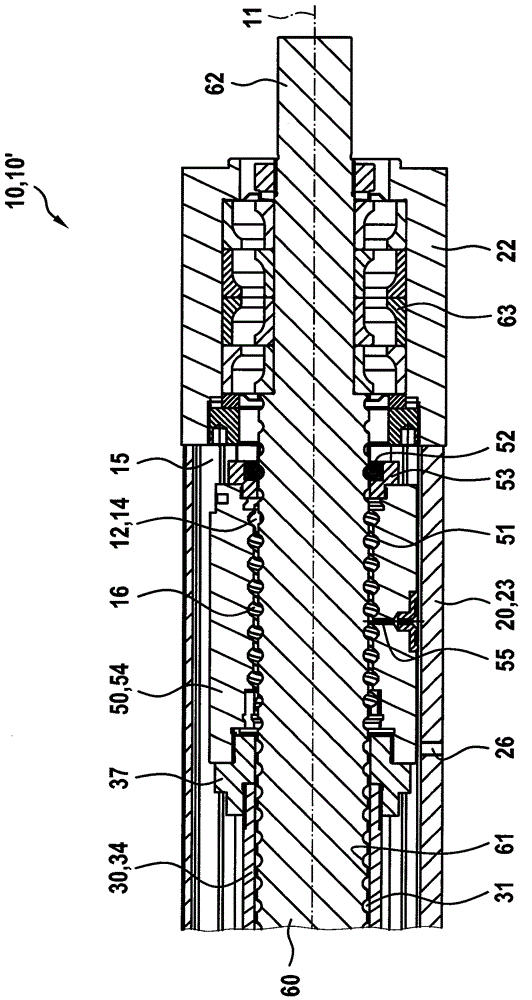

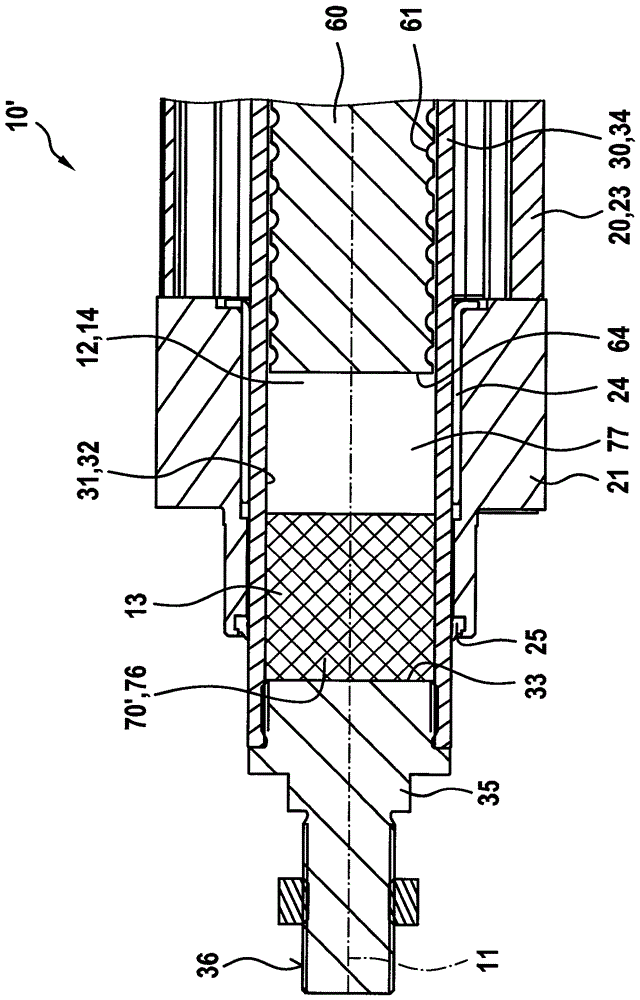

[0027] figure 1 A longitudinal section through the drive-side end of the actuator 10 according to the first embodiment of the invention is shown. The actuator 10 has a housing 20 consisting of a main body 23, a first end block (in figure 2 and 3 The middle is No. 21) and the second end block 22 is formed. The main body 23 is preferably extruded from aluminum so that it has a constant, tubular cross-sectional shape along the longitudinal axis 11 . A rotary bearing 63 is accommodated in the second end piece 22 , with which the threaded spindle 60 is mounted rotatably about the longitudinal axis 11 . The rotary bearing 63 is preferably designed in the form of a radial rolling bearing, wherein in the present case it comprises a plurality of oblique ball bearings which are pressed against one another without play. A threaded spindle 60 extends through the second end piece 22 , wherein the threaded spindle protrudes outwardly from the housing 20 with a drive journal 62 . Via t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com