Preparation method of molybdenum disulfide composite carbon composite electrode material with polyphosphazene as carbon source

A composite electrode and polyphosphazene technology, applied in the direction of negative electrode, battery electrode, secondary battery, etc., can solve the problems of volume change and unstable electrochemical performance, and achieve the effect of avoiding volume change and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take 0.064g MoS 2 In 500ml of acetonitrile solution, sonicate in an ultrasonic cell pulverizer for 1h, then transfer the solution to a 500ml round bottom flask, and sonicate in an ultrasonic bath for 30min. Then add 0.345g HCCP and 0.595gBPS into the round bottom flask, and ultrasonicate in the ultrasonic bath for 30min. Slowly add 50ml of TEA dropwise and oscillate. After the addition is complete, ultrasonicate at 300w for 5h. The solution obtained after ultrasonication was centrifuged in a high-speed centrifuge (6000r / min, 5min / time), the obtained solid was washed and centrifuged three times with absolute ethanol and deionized water respectively, and the product was dried in a vacuum oven (60°C) After 24 hours, in a tube furnace (heat up to 300°C at a speed of 5°C / min, then raise the temperature to 500°C at a speed of 2°C / min, keep warm for 1 hour, then raise the temperature to 900°C at a speed of 5°C / min, after 1 hour of heat preservation Cool down to 300°C at a ra...

Embodiment 2

[0035] Others are the same as in Example 1, except that the ultrasonic power of the reaction is 400w. The resulting MoS 2 The particles of @C composite material have better dispersibility, and the diameter is 275-385nm.

Embodiment 3

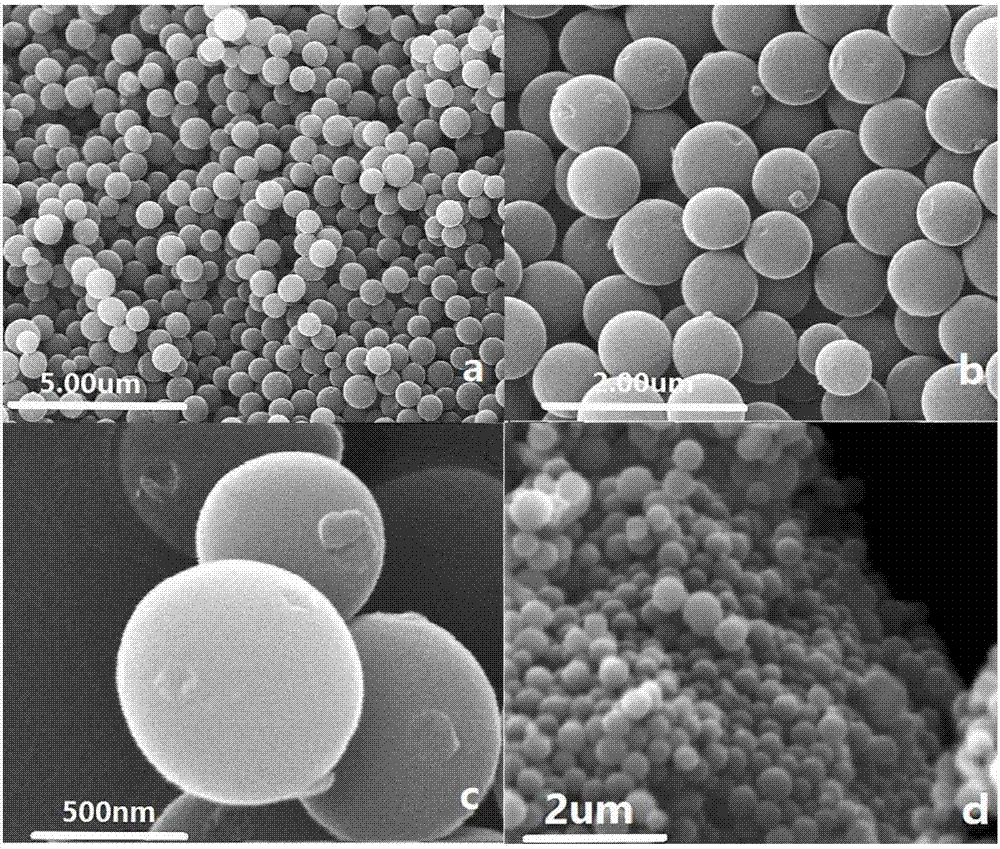

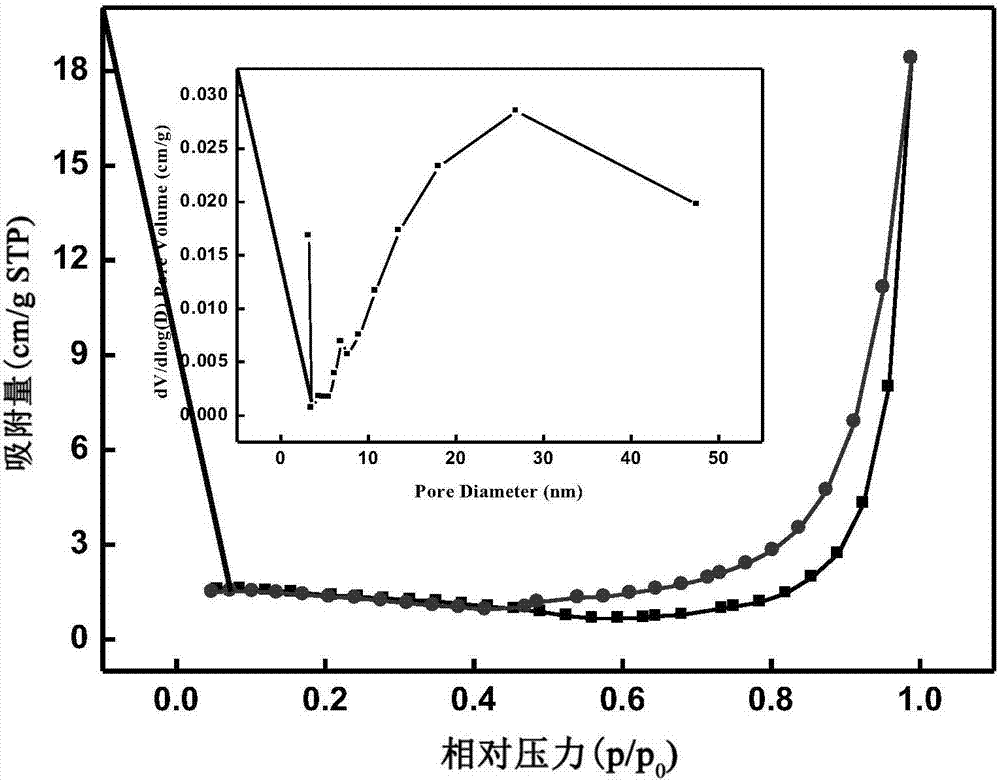

[0037] Others are the same as in Example 1, except that the ultrasonic power of the reaction is 500w. Its SEM picture see figure 1 , the desorption adsorption diagram and pore size distribution diagram of nitrogen gas are shown in figure 2 , it can be seen from the figure that the obtained MoS 2 @C composite particles have good dispersion, with a diameter of 483-502nm, and a hysteresis loop on the curve, indicating that the material has a pore structure and a specific surface area of 5.5m 2 / g, the pore volume is 0.035cm 3 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com