Solid preparation fabrication equipment and method

A technology for solid preparations and manufacturing equipment, which is applied in the direction of drying solid materials, lighting and heating equipment, and drying solid materials without heating, which can solve the problems of cumbersome processing, time-consuming and energy-consuming, and the influence of heat-sensitive substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

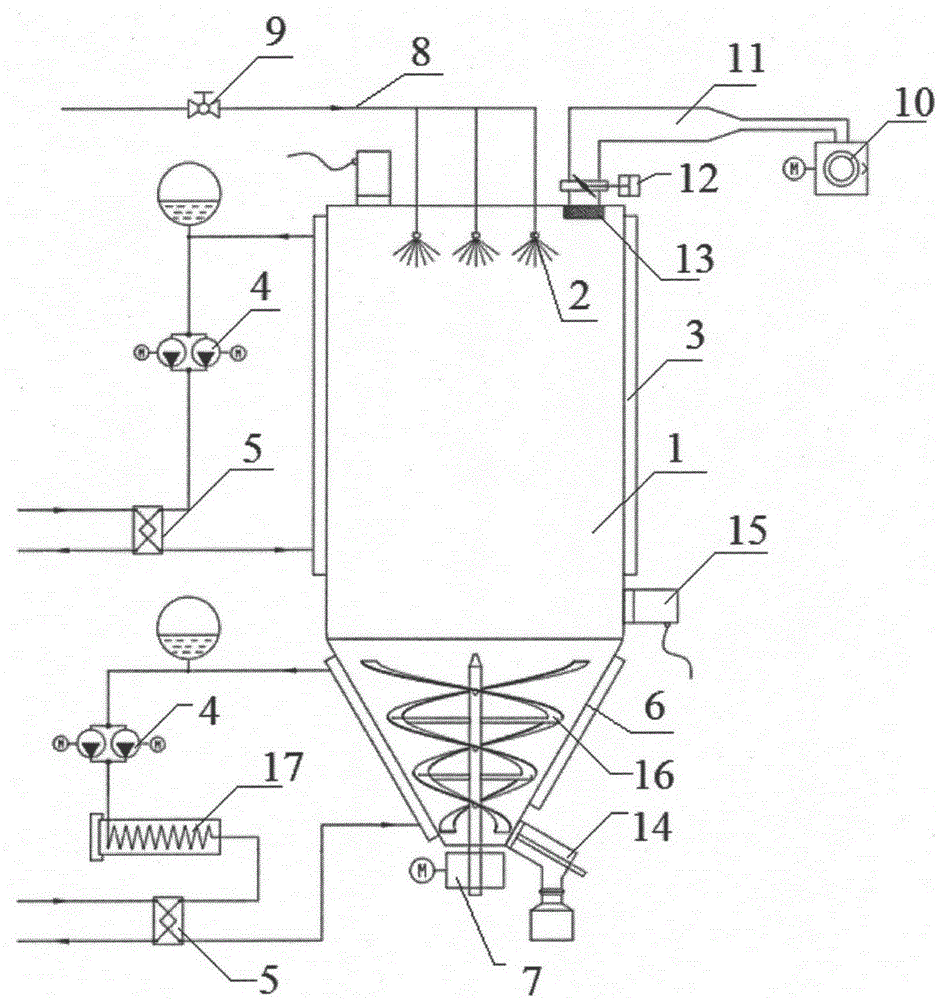

[0094] A solid preparation manufacturing equipment consists of a batch vacuum spray freeze-drying device, a mixing device and a solid preparation molding device. The solid preparation molding device is a tablet press.

[0095] Such as figure 1 As shown, the batch-type vacuum spray freeze-drying device includes: a closed container 1 for holding materials during the vacuum spray freeze-drying process; The atomizing nozzle 2 in the container 1 described above; used to form a vacuum environment in the container 1 during the vacuum spray freezing granulation stage to vaporize the ethanol in the droplets and absorb heat so that the droplets are cooled and frozen to form particles, and The drying stage is continuously vacuumed to maintain the vacuum system of the vacuum environment; and the vacuum system used for refrigeration in the vacuum spray freeze granulation stage to avoid melting of the ethanol in the granules and to provide the ethanol in the granules in the drying stage ...

Embodiment 2

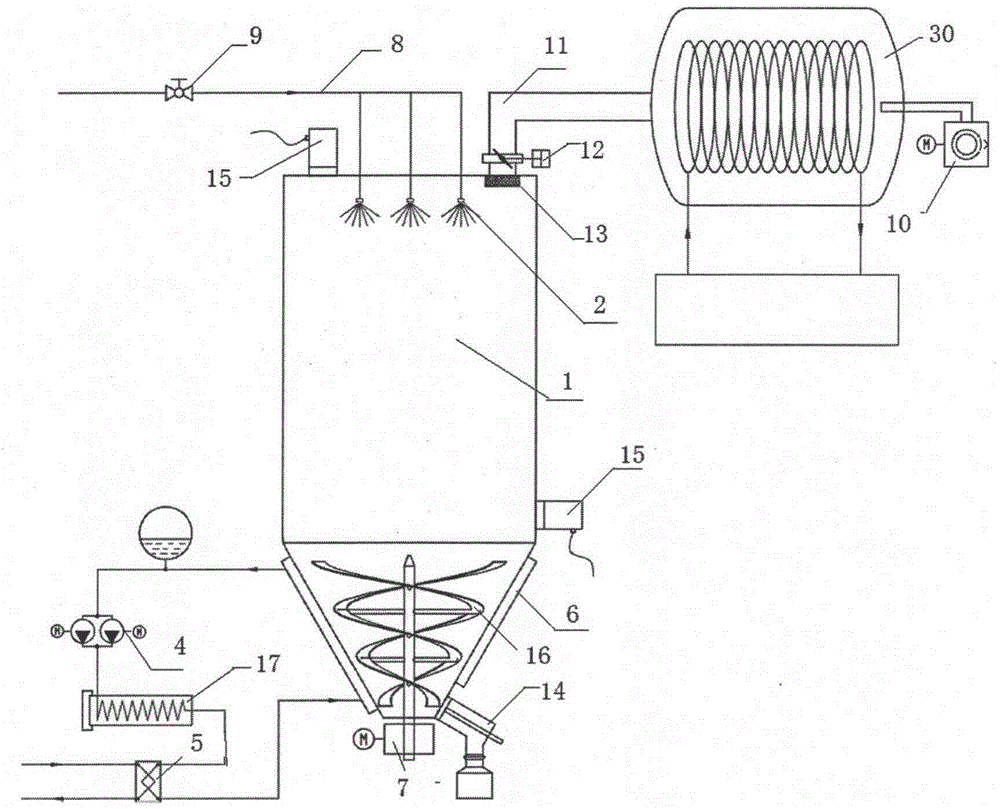

[0109] A solid preparation manufacturing equipment is composed of a batch type vacuum spray freeze drying device and a solid preparation molding device. The solid preparation forming device is a capsule filling machine ( Capsule filling machine brand: Fuchang; model: 120C ).

[0110] Such as figure 2 As shown, the batch-type vacuum spray freeze-drying device includes: a closed container 1 for holding materials during the vacuum spray freeze-drying process; The atomizing nozzle 2 in the container 1 described above; used to form a vacuum environment in the container 1 during the vacuum spray freezing granulation stage to vaporize the water in the droplets and absorb heat so that the droplets are cooled and frozen to form particles, and The drying stage is continuously vacuumed to maintain the vacuum system of the vacuum environment; and it is used for refrigeration in the vacuum spray freeze granulation stage to prevent the water in the particles from melting and to provide...

Embodiment 3

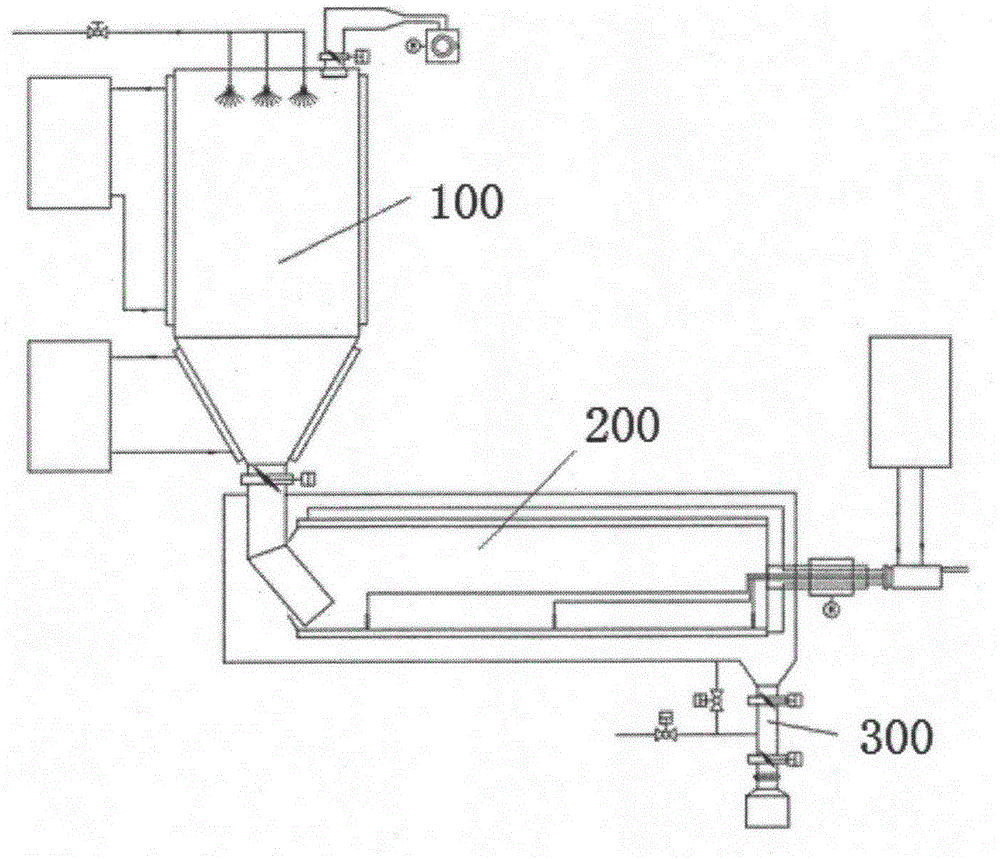

[0122] A solid preparation manufacturing equipment is composed of a continuous vacuum spray freeze-drying device, a mixing device and a solid preparation molding device. The solid preparation forming device is a capsule filling machine ( Capsule filling machine brand: Future; Model: 120C ).

[0123] Such as image 3 As shown, the continuous vacuum spray freeze-drying device includes a vacuum spray freeze-drying device 100, a dynamic heating and drying device 200, and a vacuum discharge mechanism 300 connected in sequence to form a closed container.

[0124] to combine Figure 4 , the vacuum spray freezing granulation device 100 includes a spray cylinder 1-1 for containing the product in the spray granulation process; a plurality of spray cylinders 1-1 for atomizing and dispersing the liquid to be freeze-dried into droplets and spraying them into the spray cylinder 1-1 Atomizing nozzle 1-2; a vacuum system for forming a vacuum environment in a closed container so that par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com