Saline-alkaline preventing water permeable pavement structure

A permeable pavement, saline-alkali technology, applied to roads, roads, on-site coagulation pavements, etc., can solve the problems of reducing road service life, road subsidence, increasing maintenance costs, etc., to achieve reasonable structure, long service life, Solve the effect that is easy to be corroded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

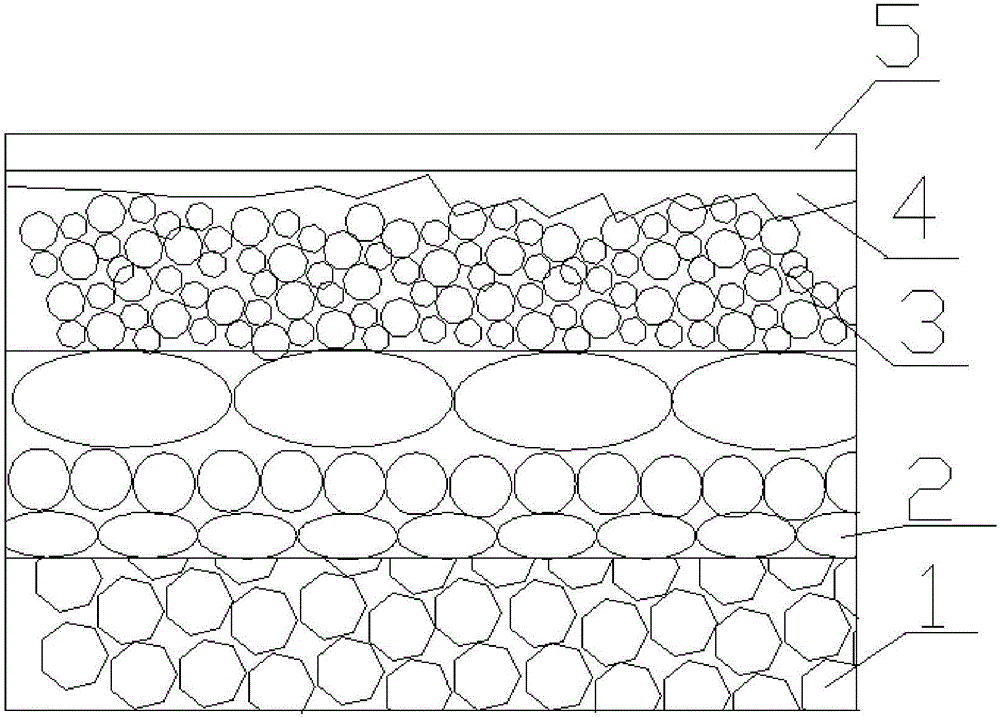

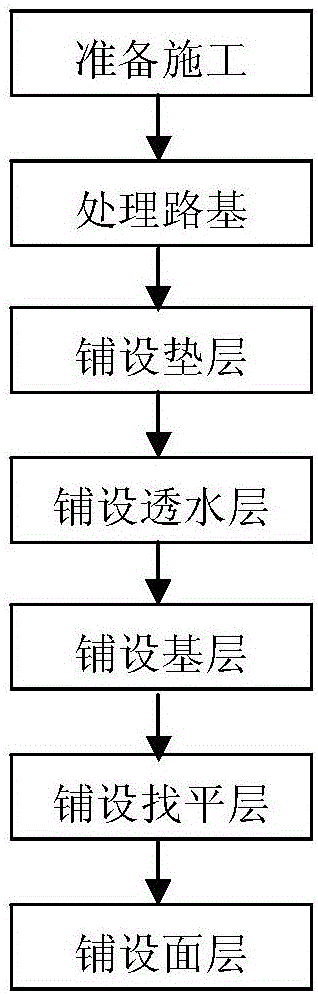

[0031] The saline-alkali-proof and permeable pavement structure involved in this embodiment includes a cushion layer 1, a water-permeable layer 2, a base layer 3, a leveling layer 4, and a surface layer 5 from bottom to top, and has the effect of preventing saline-alkali erosion. Among them, the thickness of the cushion layer 1 is 8-15mm, and its material is stone leftovers with a particle size of less than 2.36mm; the permeable layer 2 includes a 5-10mm geotextile sand bag layer laid on the bottom, a plastic drainage blind ditch layer laid in the middle and a layer laid on the upper part. The 100-200mm geotextile sand and gravel bag layer, the weight ratio of the sand and gravel in the geotextile gravel bag is 4:1, and the sand and gravel are stone leftovers of quartz sand and horn stone, with a particle size of 0.08 -1.6mm; The base layer 3 is paved with a composite material with a thickness of 50-100mm, and the weight components of each raw material are 35-60 parts of aggreg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com