Waste transformer insulating oil collection and recycling method

A technology for waste oil collection and transformer oil, applied in chemical instruments and methods, separation methods, filter regeneration, etc., to achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for collecting and recycling transformer insulating waste oil, said method comprising

[0047] 1. Establish a transformer oil recycling center to recycle waste oil;

[0048] 2. Carry out oil level monitoring and GPRS positioning for new oil barrels and waste oil barrels in substations:

[0049] The liquid level sensor monitors the oil level, and the oil level data is transmitted to the data processing module through the wireless data acquisition module, and the data processing module transmits the data to the background server through the 4G communication module;

[0050] Install GPRS positioning module on new oil drums and waste oil drums in substations;

[0051] After installing the APP application on the mobile terminal, you can browse the current liquid level schematic diagram, historical value, and location of the new oil barrels and waste oil barrels in each substation according to the authority, and you can customize the upper and lower limit alarm valu...

Embodiment 2

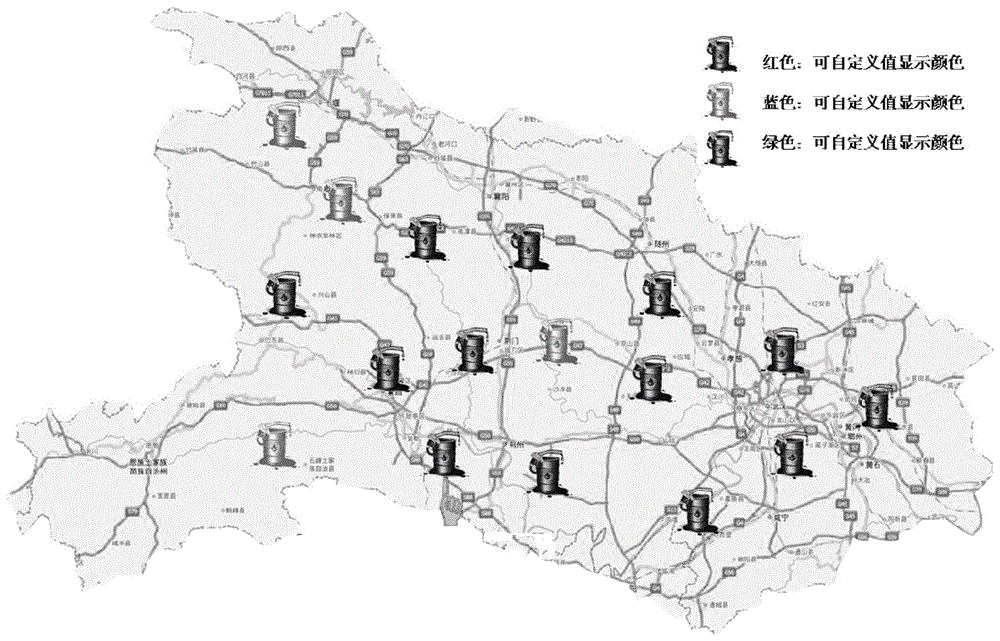

[0063] Oil level monitoring and GPRS positioning of new and waste oil barrels in 77 substations:

[0064] The liquid level sensor monitors the oil level, and the oil level data is transmitted to the data processing module through the wireless data acquisition module, and the data processing module transmits the data to the background server through the 4G communication module;

[0065] Install GPRS positioning module on new oil drums and waste oil drums in substations;

[0066] After installing the APP application on the mobile terminal, you can browse the current liquid level schematic diagram, historical value, and location of the new oil barrels and waste oil barrels in each substation according to the authority, and you can customize the upper and lower limit alarm values of the liquid level;

[0067] After the oil level monitored by the liquid level sensor reaches the alarm value, click the alarm station to generate a navigation path, and give voice prompts during the j...

Embodiment 3

[0114]Adsorbent is provided in the adsorption tank group 4 described in embodiment 1, and described adsorbent comprises the following components by weight: mass percent concentration is 25 parts of hydrochloric acid solution of 17%, and mass percent concentration is 9% sodium sulfate 24 parts of the solution, 25 parts of sodium silicate solution with a mass percent concentration of 8%, and 1.32 parts of ammonia water with a concentration of 19%. The above solutions are mixed, then aged, baked and dried to make the finished adsorbent. The aging temperature is 85° C., and the aging time is 7 hours. The drying temperature is 110°C for 4 hours, soaked in phosphoric acid, washed with water, and then baked at 135°C for 23 hours to obtain the finished adsorbent. The average pore size of the finished adsorbent reaches 10-50nm. The specific surface of the adsorbent is 300-500m 2 / g.

[0115] The degraded and polluted impurities of insulating oil are mostly macromolecules and large ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com