A kind of preparation method and special equipment of grape special fertilizer

A technology for special fertilizers and hairy grapes, applied in the application, potash fertilizer, nitrogen fertilizer and other directions, can solve the problems of falling fruit, long-term nutrient shortage of hairy grapes, and fierce competition for nutrients, and achieve the effect of increasing yield, novel equipment structure, and improving transportation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

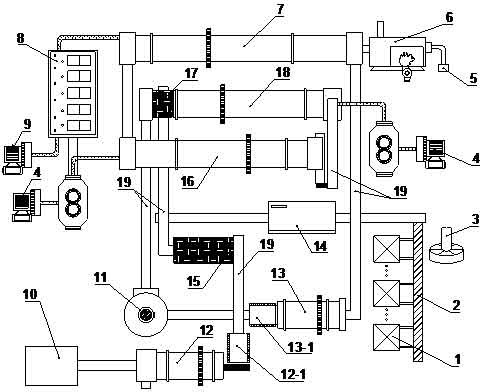

[0051] (1) Preparation method: see figure 1 , including the following steps:

[0052] (a) Measuring and weighing: Take the required raw materials separately and put them into at least two weighing buckets (1) with apron-shaped conveyor belts for weighing and measuring;

[0053] (b) Stirring and mixing: the raw materials that have been weighed in step (a) pass through the automatic water spray devices on both sides of the first conveyor belt (2) in turn, and the at least two weighing hoppers (1) are respectively fed to the The raw materials are poured into the mixer (3) one by one, and the raw materials are uniformly mixed in the mixer to obtain the mixed raw materials, wherein the natural moisture of the raw materials is kept at 5%-7% after passing through the automatic water spray device;

[0054] (c) Primary granulation: the mixed raw material obtained in step (b) passes through the second bag filter (14) and crusher (11) in sequence, the dust of the mixed raw material is r...

Embodiment 2

[0067] (1) Preparation method: see figure 1 , including the following steps

[0068] (a) Measuring and weighing: Take the required raw materials separately and put them into at least two weighing buckets (1) with apron-shaped conveyor belts for weighing and measuring;

[0069] (b) Stirring and mixing: the raw materials that have been weighed in step (a) pass through the automatic water spray devices on both sides of the first conveyor belt (2) in turn, and the at least two weighing hoppers (1) are respectively fed to the The raw materials are poured into the mixer (3) one by one, and the raw materials are uniformly mixed in the mixer to obtain the mixed raw materials, wherein the natural moisture of the raw materials is kept at 6%-8% after passing through the automatic water spray device;

[0070] (c) Primary granulation: the mixed raw material obtained in step (b) passes through the second bag filter (14) and crusher (11) in sequence, the dust of the mixed raw material is re...

Embodiment 3

[0076] (1) Preparation method: see figure 1 , including the following steps

[0077] (a) Measuring and weighing: Take the required raw materials separately and put them into at least two weighing buckets (1) with apron-shaped conveyor belts for weighing and measuring;

[0078] (b) Stirring and mixing: the raw materials that have been weighed in step (a) pass through the automatic water spray devices on both sides of the first conveyor belt (2) in turn, and the at least two weighing hoppers (1) are respectively fed to the The raw materials are poured into the mixer (3) one by one, and the raw materials are uniformly mixed in the mixer to obtain the mixed raw materials, wherein the natural moisture of the raw materials is kept at 5%-7% after passing through the automatic water spray device;

[0079] (c) Primary granulation: the mixed raw material obtained in step (b) passes through the second bag filter (14) and crusher (11) in sequence, the dust of the mixed raw material is re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com