Building 3D printing ink and use thereof

A 3D printing and ink technology, applied in the direction of additive processing, etc., can solve the problems of not being able to use 3D printing materials, use, and performance effects, etc., to achieve good toughness and fluidity, high initial setting strength, and short initial setting time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

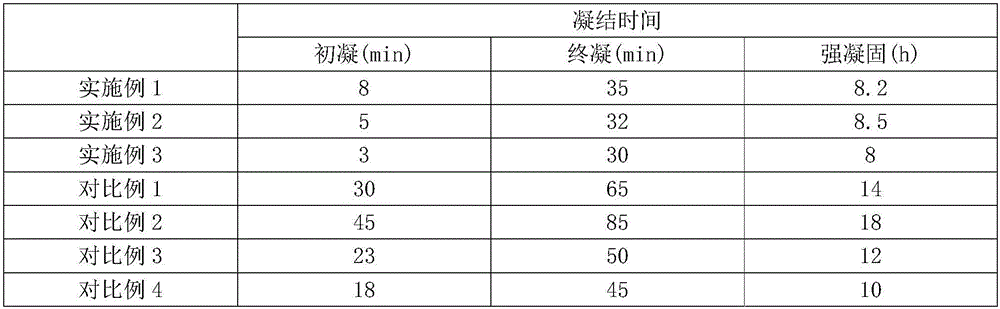

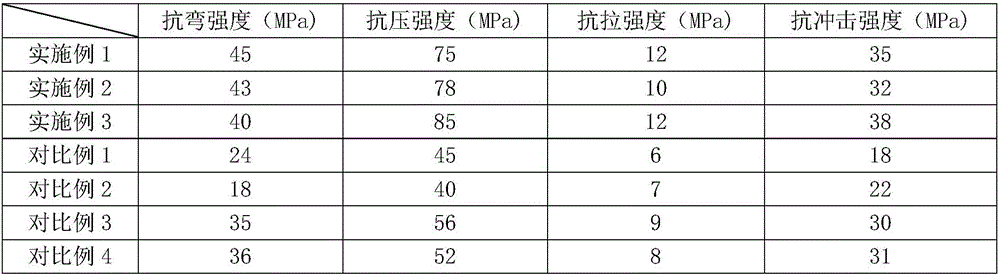

Examples

Embodiment 1

[0037] A kind of architectural 3D printing ink, send 100kg of cement and 100kg of river sand into a dry powder mixer for mixing, and the average volume of river sand is 3.4×10 -2 cm 3 , the average diameter is 6mm, the speed of the mixer is between 1000-2000r / m, the time is 30-60s, and the stirring temperature is normal temperature; take a single glass fiber with an average diameter of 0.1mm and 4kg of glass fiber, and cut the glass fiber to a length of 10- 30mm, of which 15-25mm accounts for 60%. Add the cut glass fiber to the above mixture for stirring. The mixture was sent into a mixing mixer, 50 kg of water was added, mixed and stirred evenly, and the architectural 3D printing ink of the present invention was obtained. The slump ratio index K of the 3D printing ink in Example 1 was 30%.

Embodiment 2

[0039] Present embodiment 2 does not contain small solid particle, with cement 200kg; Get single glass fiber average diameter and be 0.5mm glass fiber 5kg, glass fiber cutting length is 10-20mm and length is 20-30mm, wherein length is 10- The mass ratio of 20mm to 20-30mm single fiber is 1:1.5, the cut glass fiber is mixed with the above cement and stirred, the speed of the mixer is between 2000-2500r / s, the time is 60s, and the stirring temperature is normal temperature; Then the above-mentioned dry mixture was sent into a mixing mixer, 60kg of water was added, mixed and stirred evenly to obtain the architectural 3D printing ink of the present invention, and the slump ratio index K of the 3D printing ink in Example 2 was 35%.

Embodiment 3

[0041]Send 100kg of yellow mud and 250kg of slag into the dry powder mixer for mixing, and the average volume of slag is 0.27cm 3 , the average diameter of the slag is 8mm, the mixer speed is between 2000-2200r / s, the time is 30-45s, and the stirring temperature is normal temperature; the average diameter is 10kg of polyparaphenylene benzobisoxazole fibers of 2mm, and the poly The p-phenylene benzobisoxazole fibers are cut with a length of 10-20mm and a length of 20-30mm, wherein the mass ratio of fibers with a length of 10-20mm to 20-30mm is 1:1, and the cut polyparaphenylene The benzobisoxazole fiber is added to the above mixture and stirred, the speed of the mixer is between 2000-2500r / s, the time is 30-60s, and the stirring temperature is normal temperature; then the above-mentioned dry mixture is sent into the mixing mixer, and water is added 60kg, mixed and stirred evenly to obtain the architectural 3D printing ink of the present invention, the slump ratio index K of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com