Steel wire electric dephosphorization and mechanical descaling machine for steel cord production

A technology of steel cord and shelling machine, which is applied in the direction of removing smoke and dust, metal wire drawing, cleaning methods and utensils, etc., can solve the problems of high cost of waste acid treatment, polluted water and air, incomplete treatment, etc., and achieves good straightening effect. , Improve product quality, improve the effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

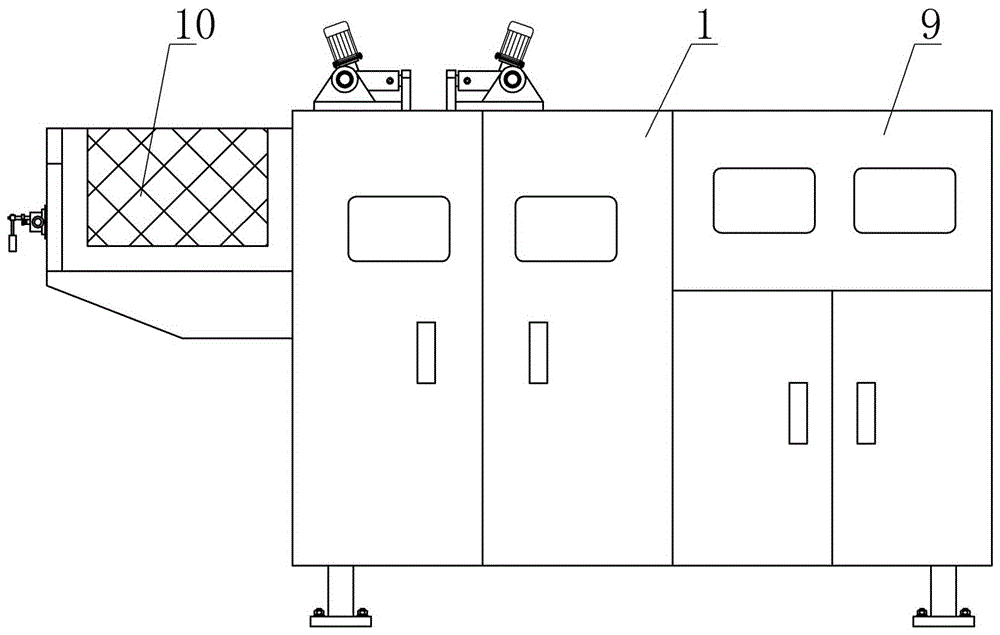

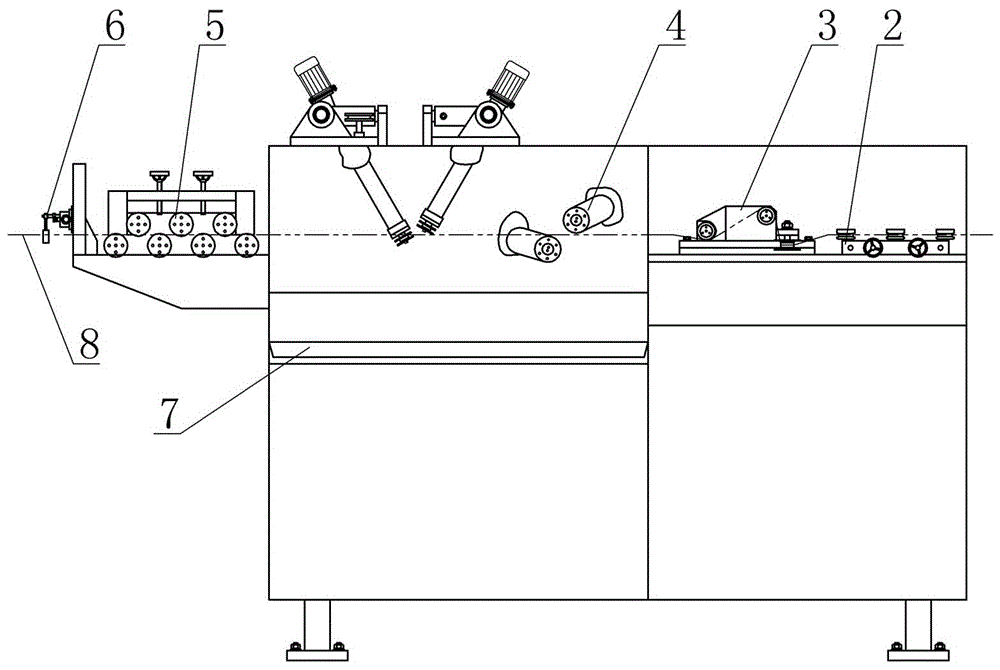

[0034] Example 1: see Figure 1 to Figure 13 , A steel wire electric dephosphorization mechanical peeling machine for the production of steel cords, comprising a box frame, a peeling device, a phosphorus removal device and a straightening device which are sequentially arranged on the box frame. It also includes a Broken wire detection device for broken wires, the broken wire detection device is arranged on the outside of the box frame, which is located at the outlet, the broken wire detection device and the dephosphorization device are electrically connected to the electrical control device of the steel cord .

[0035] The peeling device includes a first peeling mechanism and a second peeling mechanism that are sequentially arranged on the frame. The first peeling mechanism includes a peeling wheel fixing plate fixed on the frame and The first shelling wheel, the second shelling wheel, the adjusting hand wheel and the top tightening screw on the shelling wheel fixing plate, the ...

Embodiment 2

[0046] Example 2: Example 2 adds a dust cover on the basis of Example 1. The dust cover is hinged on the frame, and an observation window is opened on it. The first peeling mechanism and the second peeling mechanism are both installed in the The dustproof cover prevents the rust on the steel wire from splashing and polluting the ground and air of the workshop.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com