Alkyl anthraquinone hydrogenation catalyst and preparation method thereof

A hydrogenation catalyst, alkyl anthraquinone technology, applied in the chemical field, can solve the problems of viscosity of working fluid, influence solubility, increase of degradation products, etc., so as to reduce the occurrence of degradation reaction, reduce the generation of degradation products, and improve catalyst activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

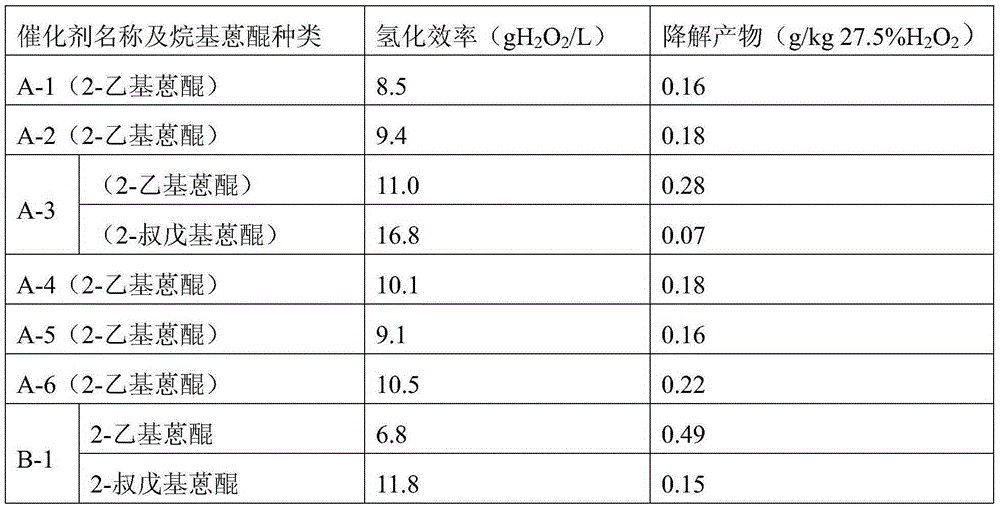

Examples

Embodiment 1

[0030] A kind of alkyl anthraquinone hydrogenation catalyst is prepared by following method:

[0031] (1) Preparation of CNTs-TiO by chemical vapor deposition 2 Complex:

[0032] A. Weigh 3g TiO 2 (0.0375mol) impregnated in 15ml 2mol / L Ni(NO 3 ) 2 (0.03mol) aqueous solution, stirred at room temperature for 15h, and dried at 105°C for 12h to obtain supported Ni(NO 3 ) 2 TiO 2 Precursor;

[0033] B. Place the precursor obtained in step A in the constant temperature zone of the tube furnace, N 2 After the temperature rises to 450°C under the protective atmosphere (flow rate 20ml / min), the atmosphere is switched to N 2 / H 2 (N 2 with H 2 The volume ratio is 2:1, the total flow rate is 120ml / min); in N 2 / H 2 Restore in a mixed atmosphere for 50 minutes, keep the atmosphere unchanged and raise the temperature to 800°C, then switch the atmosphere to N 2 / C 2 h 2 (N 2 with C 2 h 2 The volume ratio is 2:1, the total flow rate is 120ml / min); in N 2 / C 2 h 2 After ...

Embodiment 2

[0039] A kind of alkyl anthraquinone hydrogenation catalyst is prepared by following method:

[0040] (1) Preparation of CNTs-TiO by chemical vapor deposition 2 Complex:

[0041] A. Weigh 5g TiO 2 (0.0626mol) impregnated in 25ml 3mol / L Ni(NO 3 ) 2 (0.075mol) aqueous solution, stirred at room temperature for 12h, and dried at 105°C for 12h to obtain supported Ni(NO 3 ) 2 TiO 2 Precursor;

[0042] B. Place the precursor obtained in step A in the constant temperature zone of the tube furnace, N 2 Protective atmosphere (N 2 After the temperature rises to 450°C at a flow rate of 40ml / min), the atmosphere is switched to N 2 / H 2 (N 2 with H 2 The volume ratio is 2:1, the total flow rate is 150ml / min); in N 2 / H 2 Restore in a mixed atmosphere for 60 minutes, keep the atmosphere unchanged and raise the temperature to 800°C, then switch the atmosphere to N 2 / C 2 h 2 (N 2 with C 2 h 2 The volume ratio is 2:1, the total flow rate is 150ml / min); in N 2 / C 2 h 2 Af...

Embodiment 3

[0048] A kind of alkyl anthraquinone hydrogenation catalyst is prepared by following method:

[0049] (1) Preparation of CNTs-TiO by chemical vapor deposition 2 Complex:

[0050] A. Weigh 10g TiO 2 (0.1252mol) impregnated in 50ml 4mol / L Ni(NO 3 ) 2 (0.2mol) aqueous solution, stirred at room temperature for 20h, and dried at 105°C for 15h to obtain supported Ni(NO 3 ) 2 TiO 2 Precursor;

[0051] B. Place the precursor obtained in step A in the constant temperature zone of the tube furnace, N 2 Protective atmosphere (N 2 After the temperature rises to 500°C at a flow rate of 40ml / min), the atmosphere is switched to N 2 / H 2 (N 2 with H 2 The volume ratio is 3:1, the total flow rate is 120ml / min); in N 2 / H 2 Restore in a mixed atmosphere for 40 minutes, keep the atmosphere unchanged and raise the temperature to 650°C, then switch the atmosphere to N 2 / C 2 h 2 (N 2 with C 2 h 2 The volume ratio is 3:1, the total flow rate is 120ml / min); in N 2 / C 2 h 2 Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com