Selective hydrogenation method for conjugated diene latex

A conjugated diene, selective technology, applied in the field of selective hydrogenation of conjugated diene latex, to achieve the effect of low temperature and pressure, high catalytic activity, and high hydrogenation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

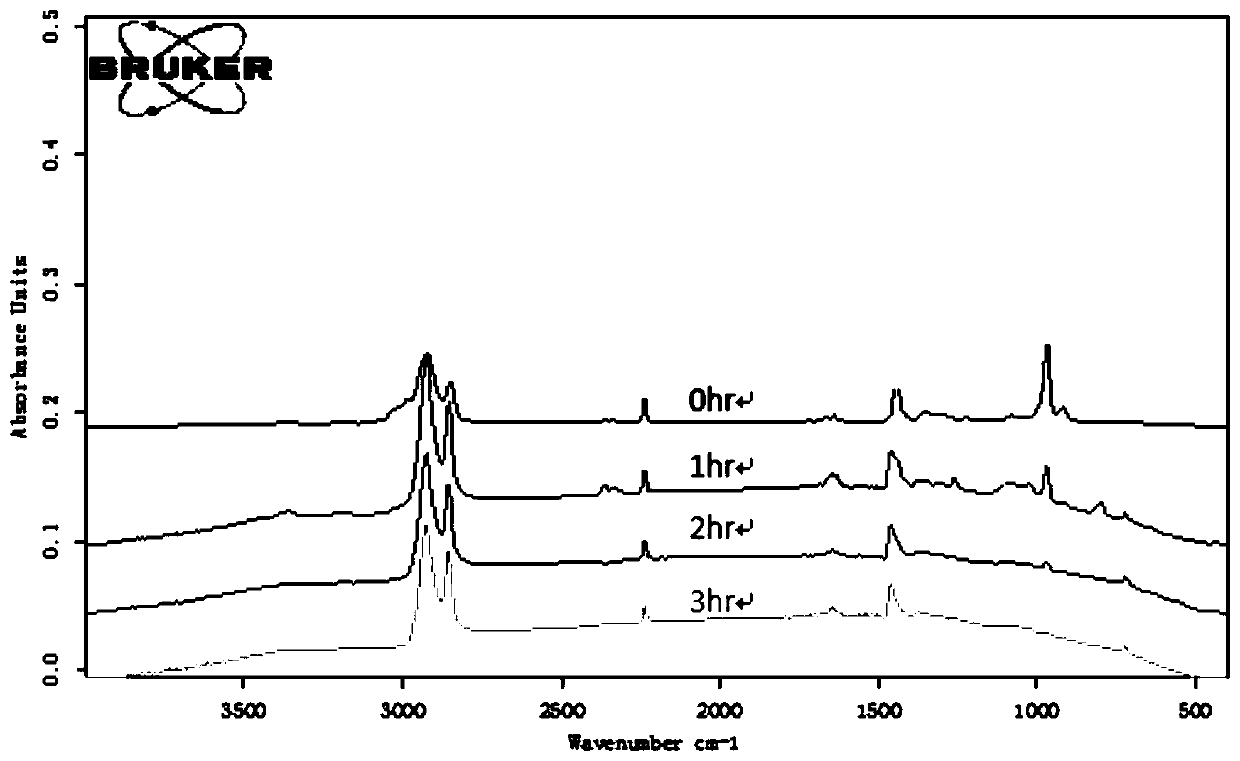

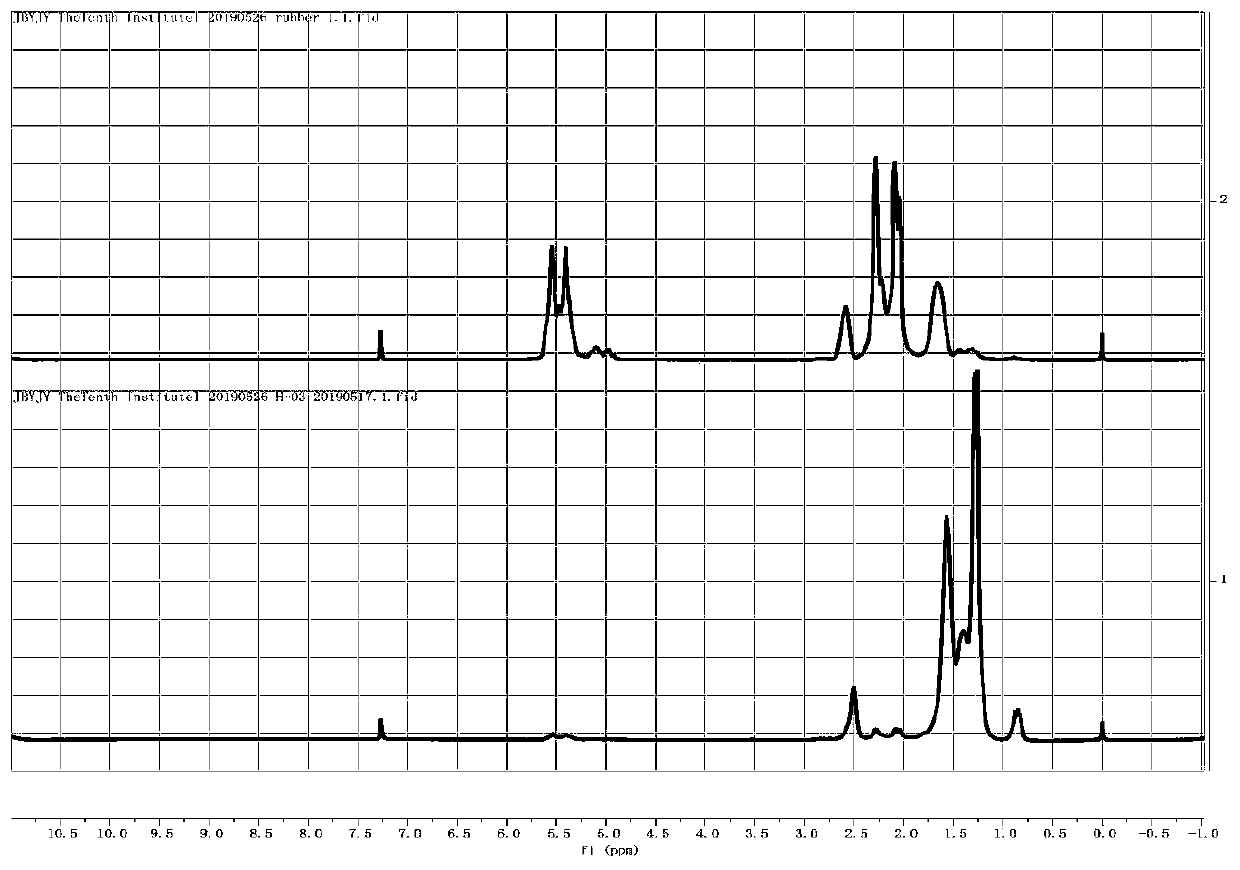

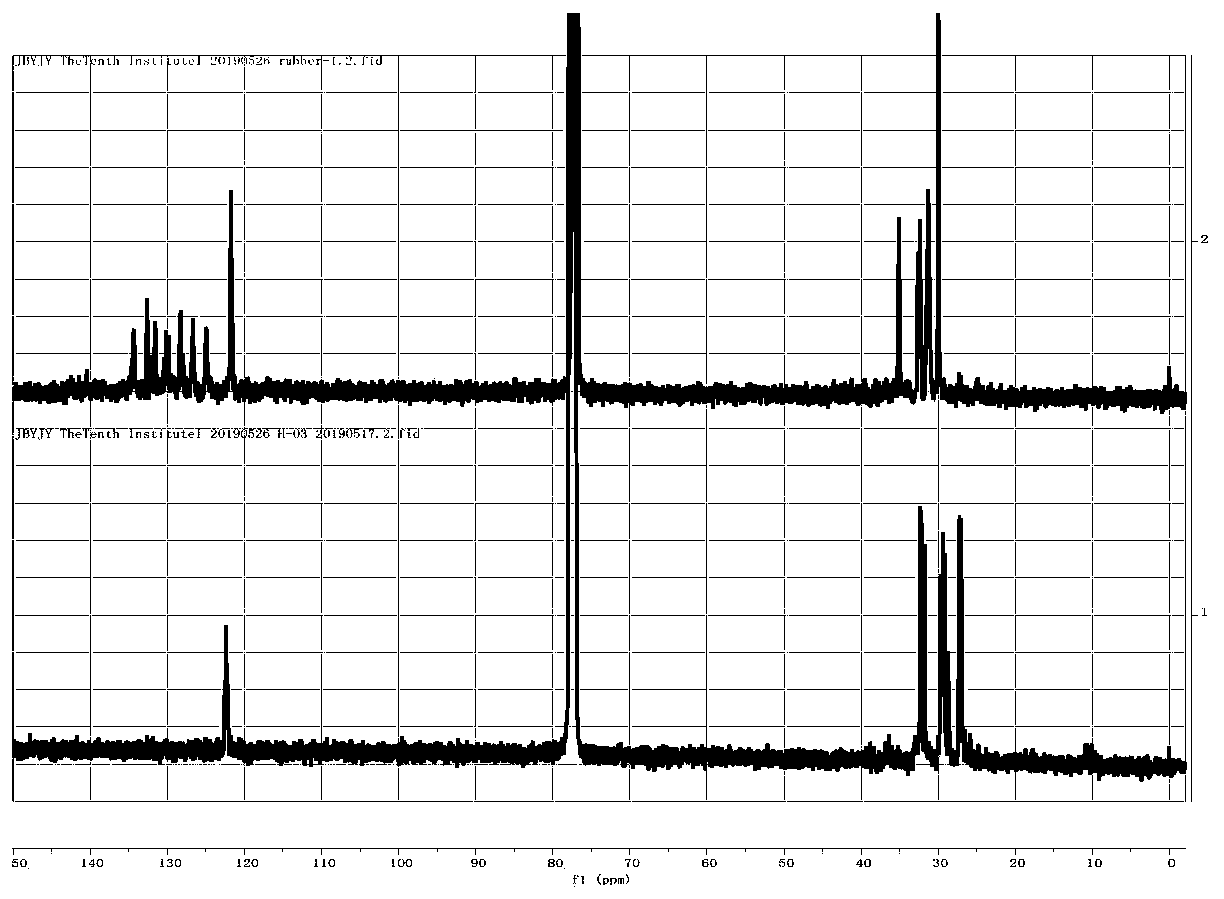

Embodiment 1

[0161] Heveda-Grubbs II Catalyst

[0162] A 300 mL polytetrafluoroethylene high pressure reactor (Parr Instruments) with temperature control, stirrer and hydrogen addition point was used. A smooth butadiene-acrylonitrile polymer latex with an acrylonitrile content of about 33% by weight and a Mooney viscosity (ML1+4@100°C) of 55 was used. The solids content of the latex was 23.6% by weight. The average diameter of the polymer particles in the latex is about 88 nm. The reactor was charged with 50ml of latex, 0.00212g of Hevida-Grubbs II, and then 50ml of latex was added. Then use hydrogen to degas the latex. The degassing temperature is 25°C, the degassing pressure is 2Mpa, the degassing time is 60min, and the stirring speed during degassing is 200rpm. After the degassing is completed, continue to stir for 4h to facilitate the full dispersion of the catalyst. For activation, raise the temperature to 90°C, raise the hydrogen pressure to 1000psi (6.89MPa), and react for 3h. A...

Embodiment 2

[0165] Heveda-Grubbs II Catalyst

[0166]A 300 mL polytetrafluoroethylene high pressure reactor (Parr Instruments) with temperature control, stirrer and hydrogen addition point was used. A smooth butadiene-acrylonitrile polymer latex with an acrylonitrile content of about 33% by weight and a Mooney viscosity (ML1+4@100°C) of 55 was used. The solids content of the latex was 23.6% by weight. The average diameter of the polymer particles in the latex is about 88 nm. The reactor was charged with 50ml of latex, 0.000236g of Hevida-Grubbs II, and then 50ml of latex. Then use hydrogen to degas the latex. The degassing temperature is 25°C, the degassing pressure is 2Mpa, the degassing time is 60min, and the stirring speed during degassing is 200rpm. After the degassing is completed, continue to stir for 4h to facilitate the full dispersion of the catalyst. For activation, raise the temperature to 90°C, raise the hydrogen pressure to 1000psi (6.89MPa), and react for 6h. After the r...

Embodiment 3

[0169] Heveda-Grubbs II Catalyst

[0170] A 300 mL polytetrafluoroethylene high pressure reactor (Parr Instruments) with temperature control, stirrer and hydrogen addition point was used. A smooth butadiene-acrylonitrile polymer latex with an acrylonitrile content of about 33% by weight and a Mooney viscosity (ML1+4@100°C) of 55 was used. The solids content of the latex was 23.6% by weight. The average diameter of the polymer particles in the latex is about 88 nm. The reactor was charged with 50ml of latex, 0.000118g of Hevida-Grubbs II, and then 50ml of latex. Then use hydrogen to degas the latex. The degassing temperature is 25°C, the degassing pressure is 2Mpa, the degassing time is 60min, and the stirring speed during degassing is 200rpm. After the degassing is completed, continue to stir for 4h to facilitate the full dispersion of the catalyst. For activation, raise the temperature to 90°C, raise the hydrogen pressure to 1000psi (6.89MPa), and react for 12h. After the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com