Suspended bed hydrogenation combination process and system

A combined process and suspended bed technology, applied in the petroleum industry, hydrocarbon oil cracking and other directions, can solve the problem of reducing the activity of hydrogenation catalysts, and achieve the effects of reducing the addition amount, delaying the deactivation time and improving the hydrogenation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

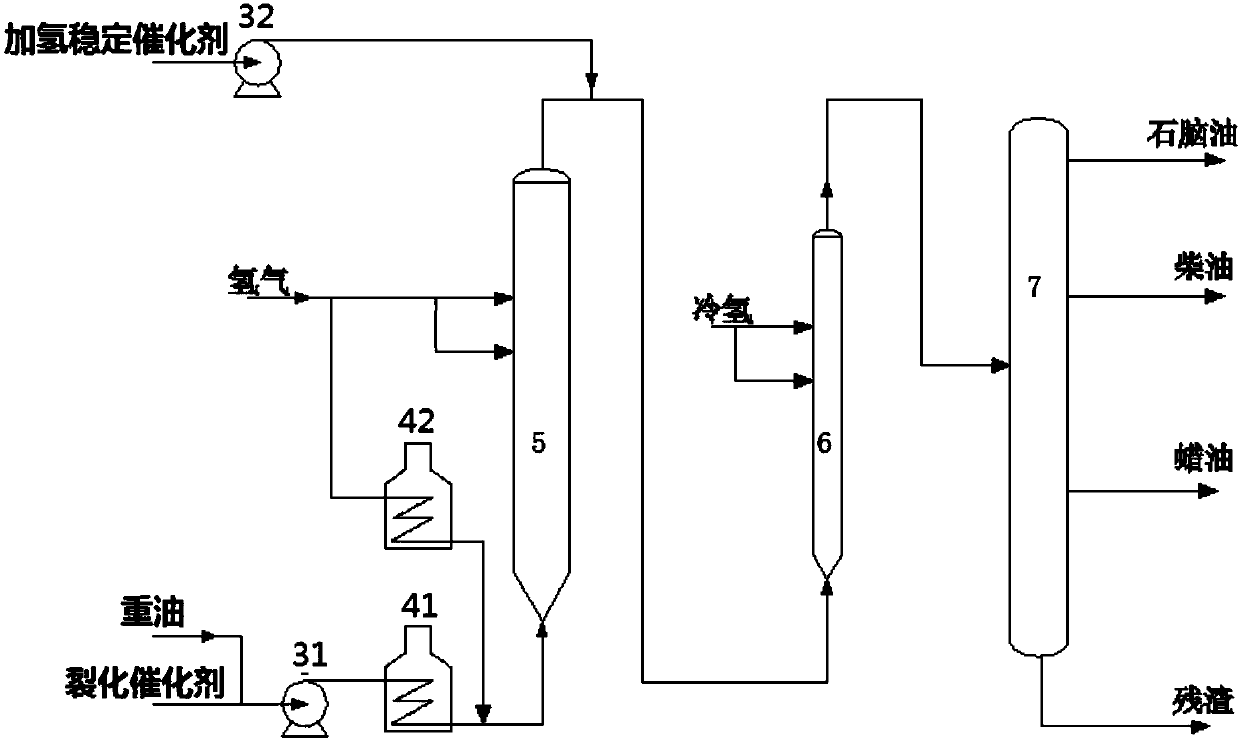

[0031] This embodiment provides a suspended bed hydrogenation combined system, such as figure 1 As shown, the suspended bed hydrocracking reactors 5 connected in series are included. It also includes a first conveying assembly 31 and a second conveying assembly 32 respectively arranged at the entrance of the suspended bed hydrocracking reactor 5 and the entrance of the suspended bed hydrogenation stabilization reactor 6 for conveying materials; the conveying assembly 31 , 32 are independently selected from but not limited to booster pumps, lock hoppers and other conveying equipment; as an embodiment of the present invention, in this embodiment, both the first conveying assembly 31 and the second conveying assembly 32 are booster pumps.

[0032] The combined hydrogenation system also includes a suspension bed separation system 7 arranged at the outlet of the suspension bed hydrogenation stabilization reactor 6 for further separating the materials treated by the suspension bed h...

Embodiment 2

[0037] This embodiment provides a suspended bed hydrogenation combined process, including the following steps:

[0038] S1, the heavy oil and the cracking catalyst are mixed and transported to the suspension bed hydrocracking reactor 5 by the second reciprocating pump for high temperature cracking;

[0039] In this embodiment, the cracking catalyst includes activated carbon and kaolin fine powder, the weight ratio of activated carbon to kaolin fine powder is 3:2, and the particle size of the cracking catalyst is 80 microns to 100 microns;

[0040] S2. The high-temperature cracking product is mixed with a hydrogenation-stabilizing catalyst and then transported to the suspension-bed hydrogenation-stabilization reactor 6, where hydrogenation is refined in the suspension-bed hydrogenation-stabilization reactor 6;

[0041] In this embodiment, the hydrogenation stable catalyst is a solid catalyst supported by solid alumina as a support for hydrogenation active metals such as Co, Mo,...

Embodiment 3

[0050] This embodiment provides a suspended bed hydrogenation combined process, comprising the following steps:

[0051] S1. Heavy oil and cracking catalyst are mixed and sent to the suspension bed hydrocracking reactor for high temperature cracking;

[0052] In this embodiment, the cracking catalyst includes activated carbon and kaolin fine powder, the weight ratio of activated carbon to kaolin fine powder is 4:2, and the particle size of the cracking catalyst is 60 microns to 80 microns;

[0053] S2. The high-temperature cracked product is mixed with a hydrogenation-stabilizing catalyst and transported to a suspension-bed hydrogenation-stabilization reactor, where hydrogenation is refined in the suspension-bed hydrogenation-stabilization reactor;

[0054] In this embodiment, the hydrogenation stable catalyst is a solid catalyst supported by solid alumina as a support for hydrogenation active metals such as Co, Mo, Ni, etc., and the particle size of the hydrogenation stable c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com