A s-band comb-line bandpass filter based on ltcc technology

A band-pass filter and comb-line technology, applied in the field of S-band comb-line band-pass filter, can solve problems such as the inability to meet the requirements of miniaturization, and achieve increased out-of-band suppression capability, shortened distance, and low insertion loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

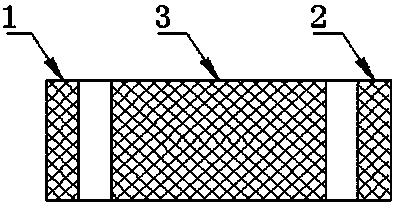

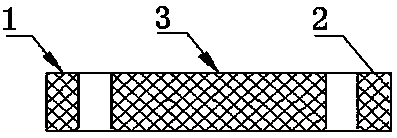

Image

Examples

Embodiment 1

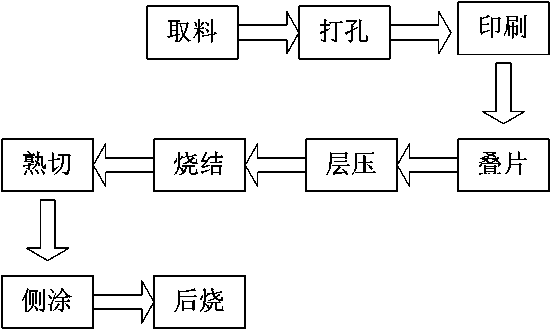

[0052] The method for making S band comb line bandpass filter comprises the following steps:

[0053] 1. Taking materials: take 21 pieces of Dupont 951C2 raw porcelain belts;

[0054] 2. Punching: punching a single piece of porcelain tape;

[0055] 3. Printing: Print metallized graphics on the front of the 5th, 10th, 11th, 12th, 13th, and 21st layer porcelain tapes and the back of the 1st layer of porcelain tapes, of which the 10th, 11th, and 12th layers 1. The metal lines in the metallized metal pattern printed on the 13th layer of the four-layer porcelain tape are arranged in a crossed manner to form the four-stage resonant unit of the filter. The pattern on the 5th layer of porcelain tape constitutes a "Z" type coupling capacitor. The metallized pattern printed on the back of the porcelain tape and the first layer of porcelain tape is the pattern that constitutes the upper and lower surfaces of the final filter;

[0056] 4. Lamination: The raw porcelain tape printed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com