Method of making Schottky diode T-type anode contact air bridge electrode

A technology of Schottky diodes and manufacturing methods, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve problems such as large parasitic capacitances, achieve small anode parasitic capacitances, and improve high-frequency characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

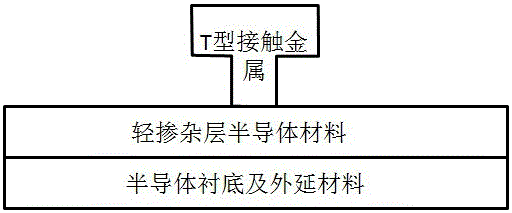

[0019] The method for making a Schottky diode T-type anode contacting an air bridge electrode comprises the following steps:

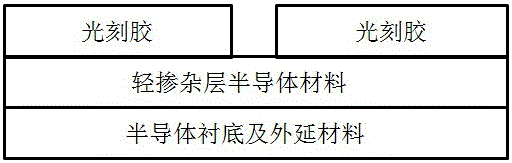

[0020] 1) Spin-coat the first layer of photoresist on the lightly doped semiconductor epitaxial material, and photoetch the first layer of circular anode contact holes with a diameter of A;

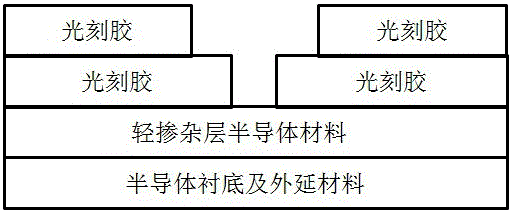

[0021] 2) Spin-coat the second layer of photoresist on the first layer of photolithographic patterns, and photoetch the second layer of anode contact holes with a diameter of B, so that the center of the circle coincides with the center of the anode contact hole of the first layer of photolithography; B The diameter is greater than the A diameter;

[0022] 3) Evaporate the anode Schottky contact metal, and remove the two layers of photoresist with organic solvent acetone, and peel off the T-shaped anode contact metal at the same time;

[0023] 4) Spin-coat photoresist and photolithography, so that there is no photoresist in the anode contact hole and the pattern ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com