A kind of inorganic fire-resistant paper and its preparation method and application

An inorganic fire-resistant and fire-resistant technology, applied in the direction of special paper, inorganic fiber/sheet, papermaking, etc., can solve the problems of low physical strength and limited application of fire-resistant paper, and achieve good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

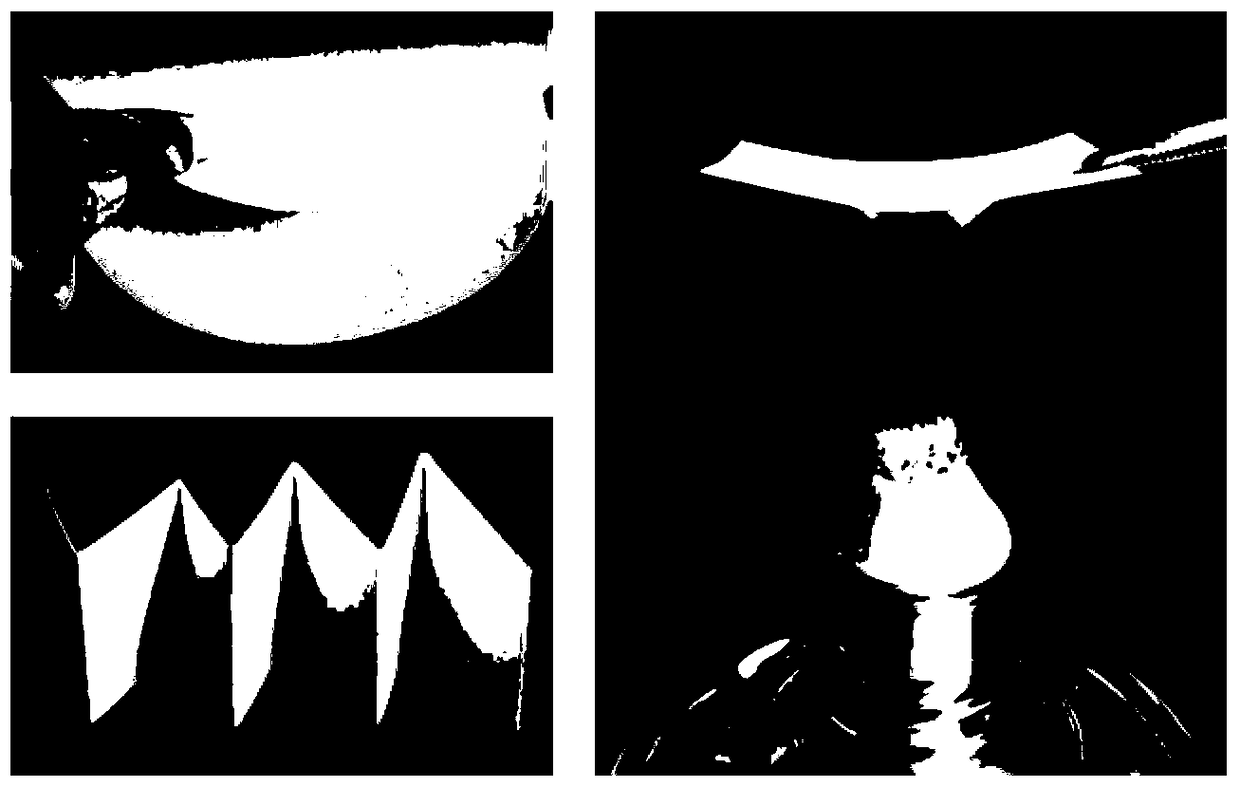

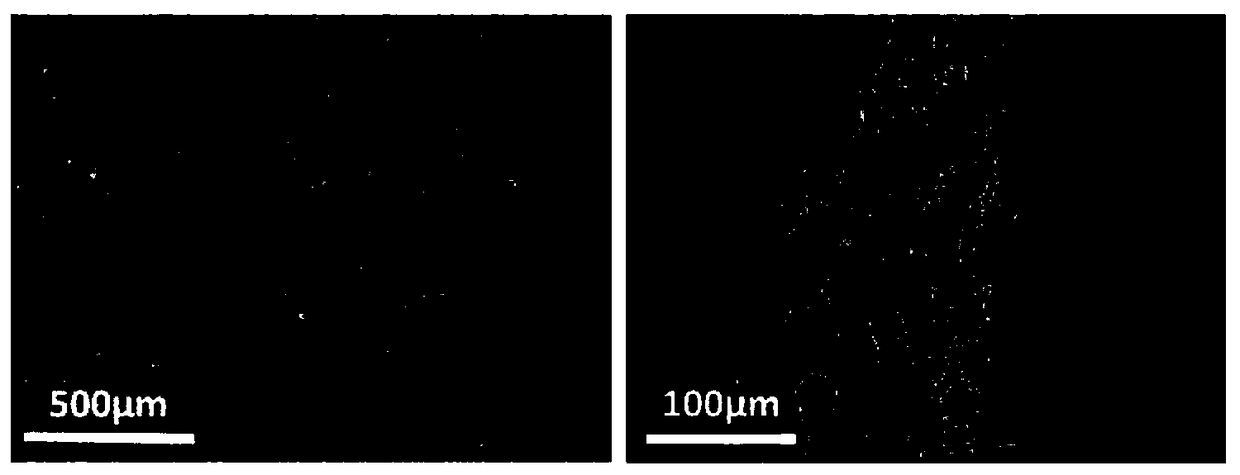

Image

Examples

Embodiment 1

[0031] A glass fiber with a length of 3 mm and a diameter of 4 μm is configured into a water suspension with a concentration of 0.5 wt.%, ultrasonically treated for 3 minutes, and then the network structure hydroxyapatite ultralong nanowires with a concentration of 0.5 wt.% are suspended in water The liquid is mixed with the glass fiber water suspension according to the proportion of 50wt.% hydroxyapatite ultra-long nanowires, and the sodium polyphosphate inorganic adhesive is added to the water suspension according to the proportion of 20wt.%, and the slurry is obtained after stirring slowly for 1 min , the slurry was filtered and formed on a Kaiser rapid paper former, and the formed paper was pressed (pressure 4MPa, time 8min) and dried (temperature 95°C, time 3min) to prepare fire-resistant paper. The fire-resistant paper has a thickness of 140 μm and a tensile strength of 5 MPa.

Embodiment 2

[0033] A glass fiber with a length of 6 mm and a diameter of 6 μm is configured into a water suspension with a concentration of 0.3 wt.%, ultrasonically treated for 3 minutes, and then the network structure hydroxyapatite ultralong nanowires with a concentration of 0.3 wt.% are suspended in water The liquid is mixed with the aluminum silicate fiber aqueous suspension according to the ratio of 60wt.% hydroxyapatite ultra-long nanowires, and the aluminum sulfate inorganic adhesive is added to the aqueous suspension according to the ratio of 20wt.%, and the slurry is obtained after stirring slowly for 1 min , the slurry was filtered and formed on a Kaiser rapid paper former, and the formed paper was pressed (pressure 1 MPa, time 10 min) and dried (temperature 65°C, time 10 min) to prepare fire-resistant paper. The fire-resistant paper has a thickness of 234 μm and a tensile strength of 8 MPa.

Embodiment 3

[0035] A glass fiber with a length of 3 mm and a diameter of 4 μm is configured into a water suspension with a concentration of 0.5 wt.%, ultrasonically treated for 3 minutes, and then the network structure hydroxyapatite ultralong nanowires with a concentration of 0.3 wt.% are suspended in water The liquid is mixed with the glass fiber water suspension according to the proportion of 70wt.% hydroxyapatite ultra-long nanowires, and boric acid and sodium silicate composite inorganic adhesive are added to the water suspension according to the proportion of 10wt.%, and stirred slowly for 1 minute to obtain Slurry, the slurry is filtered and formed on a Kaiser rapid paper former, and the formed paper is pressed (pressure 4MPa, time 8min) and dried (temperature 95°C, time 5min) to prepare fire-resistant paper . The fire-resistant paper has a thickness of 155 μm and a tensile strength of 6 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com