A method for total separation of components of papermaking black liquor

A technology for papermaking black liquor and a separation method, which is applied in the field of papermaking black liquor, can solve the problem of limiting the quality of lignin to improve the popularization and use of lignin, does not solve the problem of comprehensive utilization of inorganic substances in black liquor, and has not found comprehensive utilization of hemicellulose, etc. problems, to achieve the effect of saving cooling equipment investment, saving equipment investment, and simplifying the pretreatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

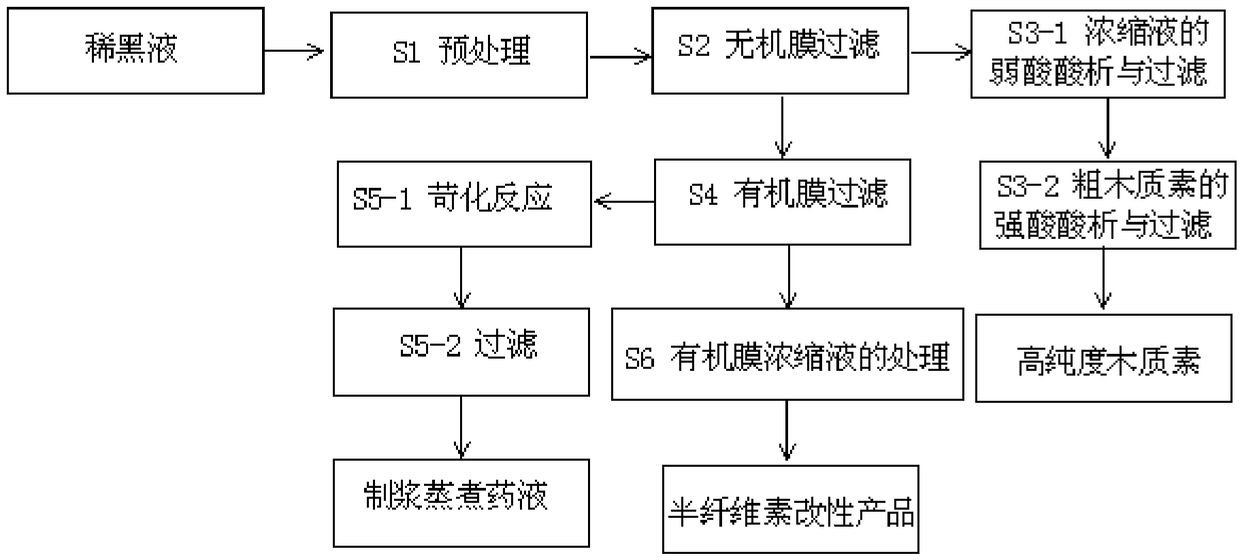

[0034] Such as figure 1 Shown:

[0035] S1. Pretreatment: transport the papermaking black liquor with a temperature of 83°C and a solid content of 16.1% to the bag filter with a pump, and the outlet pressure of the pump is 0.23MPa to remove coarse particles and hard objects in the black liquor;

[0036] S2. Inorganic membrane filtration: Then use a high-pressure pump to transport to a section of inorganic membrane filtration device. The inorganic membrane is a ceramic tubular membrane. The membrane support material of the inorganic membrane is alumina, and the membrane layer is a composite zirconium membrane. The inorganic membrane The molecular weight cut-off of the membrane filtration device is more than 3000, and the outlet pressure of the high-pressure pump is 1.0 MPa to obtain a filtrate and a concentrated solution with a solid content of 22.1%.

[0037] S3, separation of lignin:

[0038] S3-1. Weak acid acid analysis and filtration of the concentrated solution: add liq...

Embodiment 2

[0046] Such as figure 1 Shown:

[0047] S1. Pretreatment: transport the papermaking black liquor with a temperature of 79°C and a solid content of 16.5% to the bag filter with a pump, and the outlet pressure of the pump is 0.26MPa to remove coarse particles and hard objects in the black liquor;

[0048] S2. Inorganic membrane filtration: Then use a high-pressure pump to transport to a section of inorganic membrane filtration device. The inorganic membrane is a ceramic tubular membrane. The membrane support material of the inorganic membrane is alumina, and the membrane layer is a composite zirconium membrane. The inorganic membrane The molecular weight that the membrane filtration device can cut off is more than 3000, and the outlet pressure of the high pressure pump is 2.0Mpa, and the filtrate and the concentrated solution with a solid content of 22.6% are obtained.

[0049] S3, separation of lignin:

[0050] S3-1. Weak acid acid analysis and filtration of the concentrated ...

Embodiment 3

[0058] Such as figure 1 Shown:

[0059] S1. Pretreatment: transport the papermaking black liquor with a temperature of 82°C and a solid content of 16.2% to the bag filter with a pump, and the outlet pressure of the pump is 0.25MPa to remove coarse particles and hard objects in the black liquor;

[0060] S2. Inorganic membrane filtration: Then use a high-pressure pump to transport to a section of inorganic membrane filtration device. The inorganic membrane is a ceramic tubular membrane. The membrane support material of the inorganic membrane is alumina, and the membrane layer is a composite zirconium membrane. The inorganic membrane The molecular weight cut-off of the membrane filtration device is more than 3000, and the outlet pressure of the high-pressure pump is 1.2MPa to obtain a filtrate and a concentrated solution with a solid content of 23.3%.

[0061] S3, separation of lignin:

[0062] S3-1. Weak acid acid analysis and filtration of the concentrated solution: add liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com