Nylon high-shrinkage fiber and preparation method thereof

A high-shrinkage, nylon technology, used in fiber processing, conductive/antistatic filament manufacturing, conjugated synthetic polymer rayon, etc., can solve the problems of static electricity and low shrinkage, and achieve good stretching effect and high Boiling water shrinkage, good antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

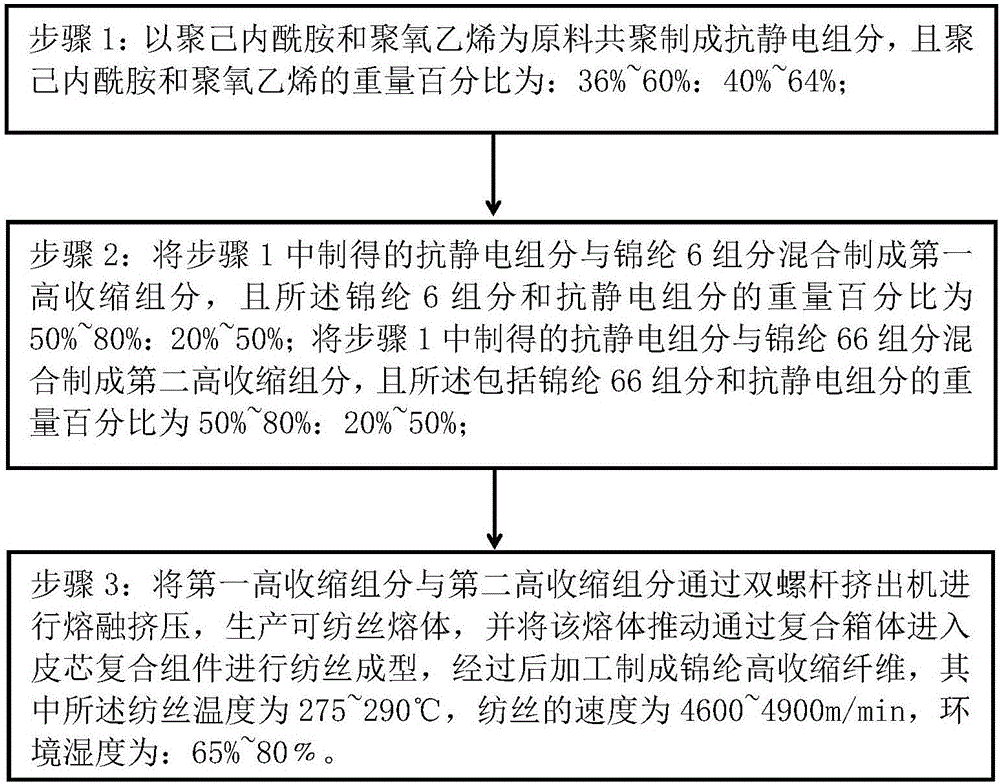

[0030] Such as figure 1 Shown, the present invention also provides a kind of preparation method of nylon high-shrinkage fiber, comprises the following steps,

[0031] Step 1: Copolymerize polycaprolactam and polyoxyethylene as raw materials to form an antistatic component, and the weight percentages of polycaprolactam and polyoxyethylene are: 36%-60%: 40%-64%;

[0032] Step 2: Mix the antistatic component prepared in step 1 with the nylon 6 component to make the first high-shrinkage component, and the weight percentage of the nylon 6 component and the antistatic component is 50% to 80% : 20% to 50%; the antistatic component prepared in step 1 is mixed with the nylon 66 component to make the second high shrinkage component, and the weight percentage of the nylon 66 component and the antistatic component is 50% to 80%: 20% to 50%;

[0033]Step 3: Melt-extrude the first high-shrinkage component and the second high-shrinkage component through a twin-screw extruder to produce a s...

Embodiment 1

[0037] A nylon high-shrinkage fiber, the nylon high-shrinkage fiber includes a first high-shrinkage component and a second high-shrinkage component, and the weight percentage of the first high-shrinkage component and the second high-shrinkage component is: 20 %: 80%, the preparation method of the nylon high-shrinkage fiber comprises the following steps,

[0038] Step 1: Copolymerize polycaprolactam and polyoxyethylene as raw materials to form an antistatic component, and the weight percentage of polycaprolactam and polyoxyethylene is: 36%: 64%;

[0039] Step 2: Mix the antistatic component prepared in step 1 with the nylon 6 component to make the first high shrinkage component, and the weight percentage of the nylon 6 component and the antistatic component is 58%: 42% ; The antistatic component prepared in step 1 is mixed with the nylon 66 component to make the second high shrinkage component, and the weight percentage of the nylon 66 component and the antistatic component is ...

Embodiment 2

[0043] A nylon high-shrinkage fiber, the nylon high-shrinkage fiber includes a first high-shrinkage component and a second high-shrinkage component, and the weight percentage of the first high-shrinkage component and the second high-shrinkage component is: 50 %: 50%, the preparation method of the nylon high-shrinkage fiber comprises the following steps,

[0044] The present invention also provides a kind of preparation method of nylon high-shrinkage fiber, comprising the following steps,

[0045] Step 1: Copolymerize polycaprolactam and polyoxyethylene as raw materials to form an antistatic component, and the weight percentage of polycaprolactam and polyoxyethylene is: 36%: 64%;

[0046] Step 2: Mix the antistatic component prepared in step 1 with the nylon 6 component to make the first high shrinkage component, and the weight percentage of the nylon 6 component and the antistatic component is 80%: 20% ; The antistatic component prepared in step 1 is mixed with the nylon 66 c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com