Transition metal chalcogenide-carbonyl iron powder composite microwave absorbent and preparation method thereof

A microwave absorbing agent, chalcogenide technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of being difficult to meet the requirements of thinness, lightness, width, strength, low corrosion resistance, and decreased wave absorption performance. Avoid adverse effects, increase absorption rate, increase dielectric loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

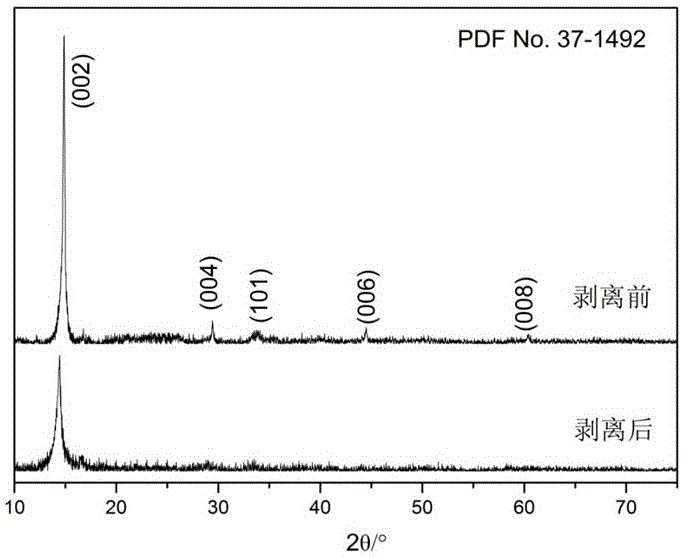

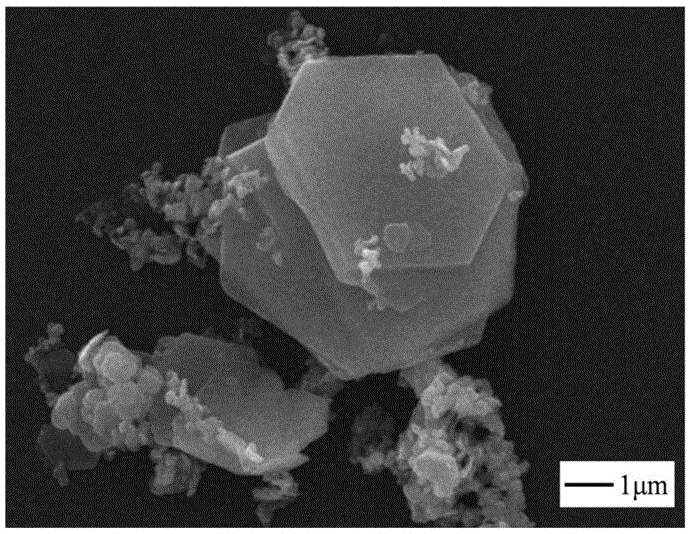

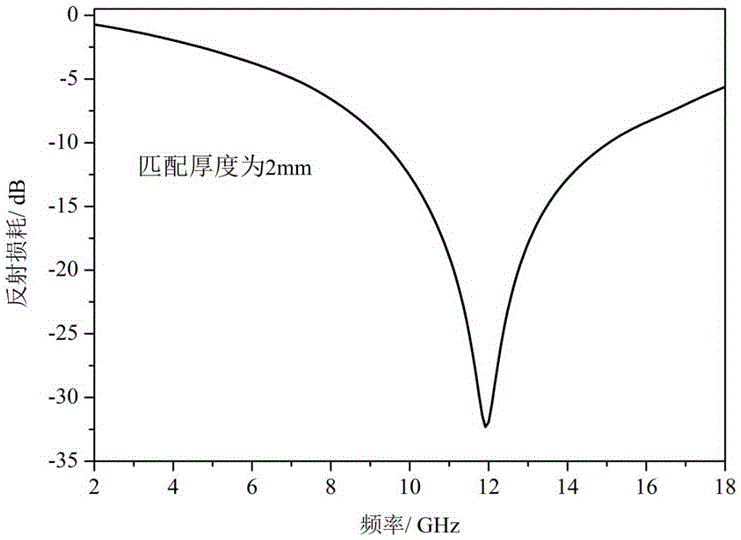

[0034] A transition metal chalcogenide-carbonyl iron powder composite microwave absorber, the composite microwave absorber is mainly composed of transition metal chalcogenide flakes and carbonyl iron powder, the chemical formula of the transition metal chalcogenide is AB 2 , where A is Mo, B is S, that is, MoS 2 . The microscopic morphology of transition metal chalcogenides is flake-like, and 0<flaky transverse grain size<4 μm.

[0035] A preparation method of the transition metal chalcogenide-carbonyl iron powder composite microwave absorber of the above-mentioned embodiment, comprising the following steps:

[0036] (1) Weigh 0.1g MoS with an analytical balance 2 Coarse powder, mixed with 50.0mL organic solvent N-methyl-2-pyrrolidone (NMP), placed in a beaker to prepare a mixed solution with a concentration of 2g / L, then sealed the beaker with plastic wrap and a rubber band, placed in In a constant-temperature ultrasonic cleaner, intermittently sonicate for 5 hours, and so...

Embodiment 2

[0041] A transition metal chalcogenide-carbonyl iron powder composite microwave absorber, the composite microwave absorber is mainly composed of transition metal chalcogenide flakes and carbonyl iron powder, the chemical formula of the transition metal chalcogenide is AB 2 , where A is Mo, B is S, that is, MoS 2 . The microscopic morphology of transition metal chalcogenides is flake-like, and 0<flaky transverse grain size<4 μm.

[0042] A preparation method of the transition metal chalcogenide-carbonyl iron powder composite microwave absorber of the above-mentioned embodiment, comprising the following steps:

[0043] (1) Weigh 0.1g MoS with an analytical balance 2 Coarse powder, mixed with 50.0mL organic solvent N-methyl-2-pyrrolidone (NMP), placed in a beaker to prepare a mixed solution with a concentration of 2g / L, then sealed the beaker with plastic wrap and a rubber band, placed in In a constant-temperature ultrasonic cleaner, intermittently sonicate for 5 hours, and so...

Embodiment 3

[0048] A transition metal chalcogenide-carbonyl iron powder composite microwave absorber, the composite microwave absorber is mainly composed of transition metal chalcogenide flakes and carbonyl iron powder, the chemical formula of the transition metal chalcogenide is AB 2 , where A is Mo, B is Se, that is, MoSe 2 . The microscopic morphology of transition metal chalcogenides is flake-like, and 0<flaky transverse grain size<10 μm.

[0049] A preparation method of the transition metal chalcogenide-carbonyl iron powder composite microwave absorber of the above-mentioned embodiment, comprising the following steps:

[0050] (1) Weigh 0.1g MoSe with an analytical balance 2 Coarse powder, mixed with 50.0mL organic solvent N-methyl-2-pyrrolidone (NMP), placed in a beaker to prepare a mixed solution with a concentration of 2g / L, then sealed the beaker with plastic wrap and a rubber band, placed in In a constant-temperature ultrasonic cleaner, intermittently sonicate for 3 hours, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com