Wearproof glass fiber communication tube product and preparation method thereof

A communication pipe and glass fiber technology, which is applied in the field of communication pipe, can solve the problems of difficult glass fiber PVC material processing, difficulty in controlling dispersion and uniformity, and reducing the toughness of PVC material, so as to enhance melt fluidity and improve thermal stability. Stability, enhanced fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

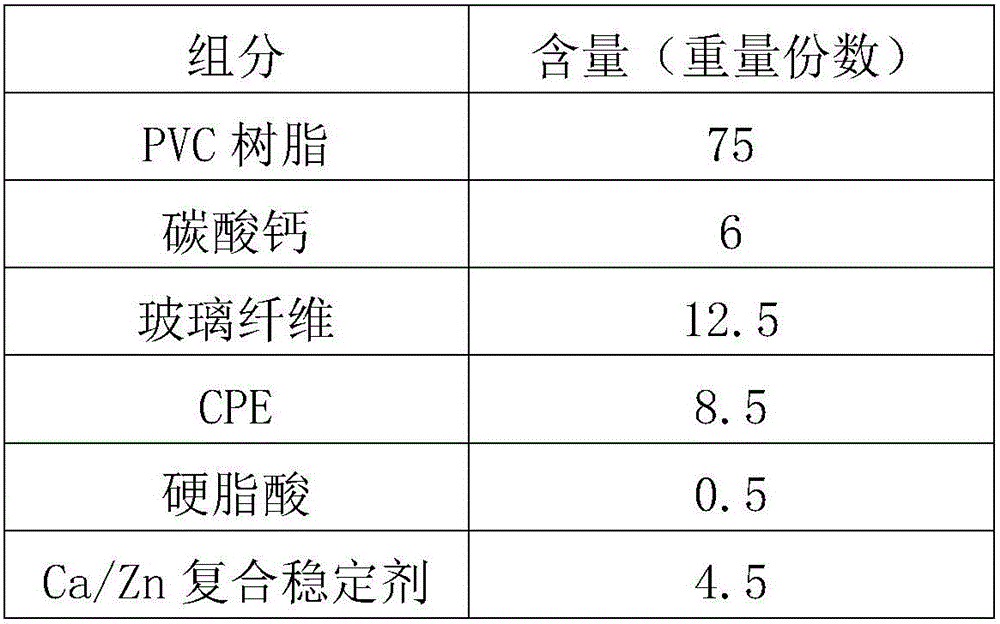

[0037] Embodiment 1 discloses a wear-resistant glass fiber communication pipe, and its formula is shown in Table 1.

[0038] Formulation table of table 1 embodiment 1

[0039] components Content (parts by weight) PVC resin 75 calcium carbonate 6 glass fiber 12.5 CPE 1.8 stearic acid 0.5 Ca / Zn Composite Stabilizer 4.5 PE wax 0.4

Embodiment 2

[0041] A wear-resistant glass fiber communication pipe is disclosed in Example 2, and its formula is shown in Table 2.

[0042] The formula table of table 2 embodiment 2

[0043] components Content (parts by weight) PVC resin 75 calcium carbonate 6 glass fiber 12.5 CPE 3.5 stearic acid 0.5 Ca / Zn Composite Stabilizer 4.5 PE wax 0.4

Embodiment 3

[0045] Example 3 discloses a wear-resistant glass fiber communication pipe, the formula of which is shown in Table 3.

[0046] Formulation table of table 3 embodiment 3

[0047]

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com