Method for preparing cellulose nanocrystalline sponge material

A cellulose and nanocrystal technology, applied in the field of preparation of cellulose nanocrystals, can solve the problems of inconvenient storage and use, inability to reuse, weak enhancement effect, etc., and achieves cost recovery, simple and easy experimental operation, and shape recovery. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

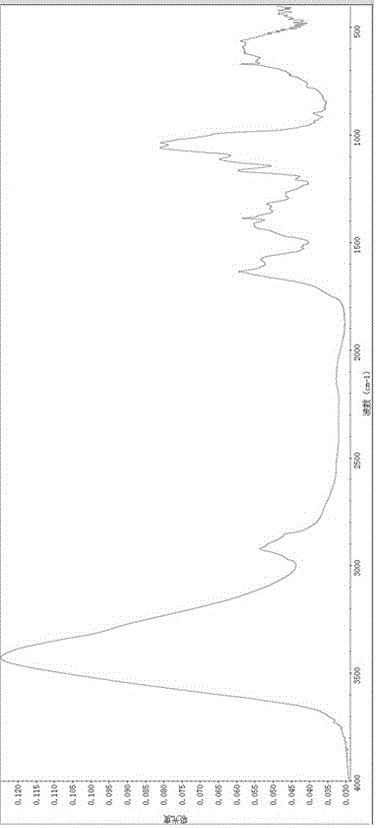

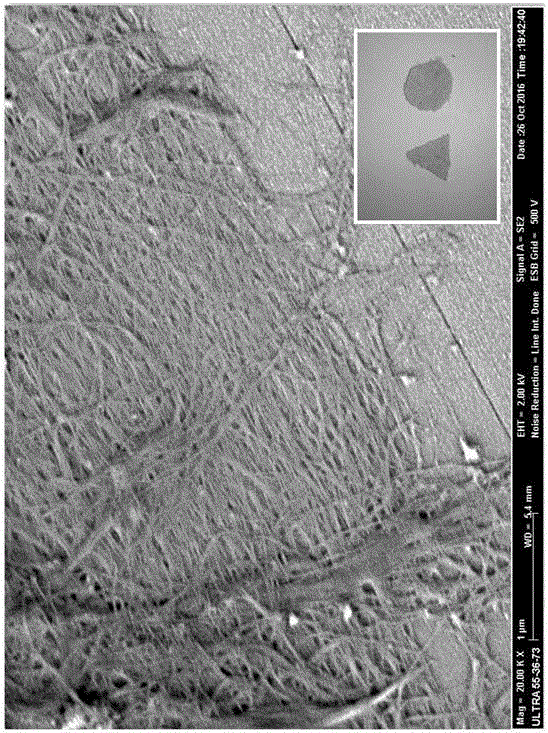

[0022] After cleaning and shredding the waste ginger fiber, mix it with a mixed acid solution formed by mixing formic acid with a concentration of 6mol / L and hydrochloric acid with a concentration of 6mol / L at a solid-liquid ratio of 1:100g / mL, wherein the volume ratio of formic acid and hydrochloric acid 5:5, put it in a hydrothermal kettle, react in an oven at 110°C for 3 hours, add ammonia water dropwise after the reaction to adjust the pH value to 7, centrifuge and wash 3 times, and freeze-dry it in a plastic mold at -50°C for 12 hours. The spongy cellulose nanocrystalline material (a) is obtained. Observing under a scanning electron microscope, the length of the cellulose nanorod is 500-1000nm, the diameter is 5-40nm, and the aspect ratio is 25-200.

Embodiment 2

[0024] After cleaning and shredding the waste cotton fiber, mix it with a mixed acid solution formed by mixing citric acid with a concentration of 3mol / L and hydrochloric acid with a concentration of 6mol / L at a solid-liquid ratio of 1:75g / mL, wherein the citric acid and hydrochloric acid The volume ratio is 7:3, put it into a hydrothermal kettle, and react in an oven at 120°C for 4 hours. After the reaction, add ammonia water dropwise to adjust the pH value to 7, centrifuge and wash 4 times, and put it in a plastic mold at -50°C to freeze dry After 24 hours, the spongy cellulose nanocrystalline material (b) was obtained. The obtained cellulose nanorods have a length of 600-1200nm, a diameter of 5-50nm and an aspect ratio of 25-240 observed under a scanning electron microscope.

Embodiment 3

[0026] Coconut fiber is washed and shredded and mixed with the mixed acid solution formed by mixing the formic acid of 6mol / L and the hydrochloric acid of 6mol / L by the solid-liquid ratio, wherein the volume ratio of formic acid and hydrochloric acid is 9:1, put it into a hydrothermal kettle, react in an oven at 130°C for 5 hours, add ammonia water dropwise after the reaction to adjust the pH value to 7, centrifuge and wash 3 times, put it in a plastic mold at -50°C and freeze-dry for 48 hours to obtain Sponge-like cellulose nanocrystalline material (c). Observing under a scanning electron microscope, the length of the cellulose nanorod is 500-1500nm, the diameter is 5-40nm, and the aspect ratio is 25-300.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com