Special fertilizer for brassica juncea and preparation method

A technology for special fertilizer and kohlrabi, which is applied in the field of special fertilizer for kohlrabi and its preparation, which can solve the problems of increased heavy metal content, soil agglomeration, single raw material, etc., and achieve the effect of strengthening the effect of heavy metals, increasing the body surface area, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

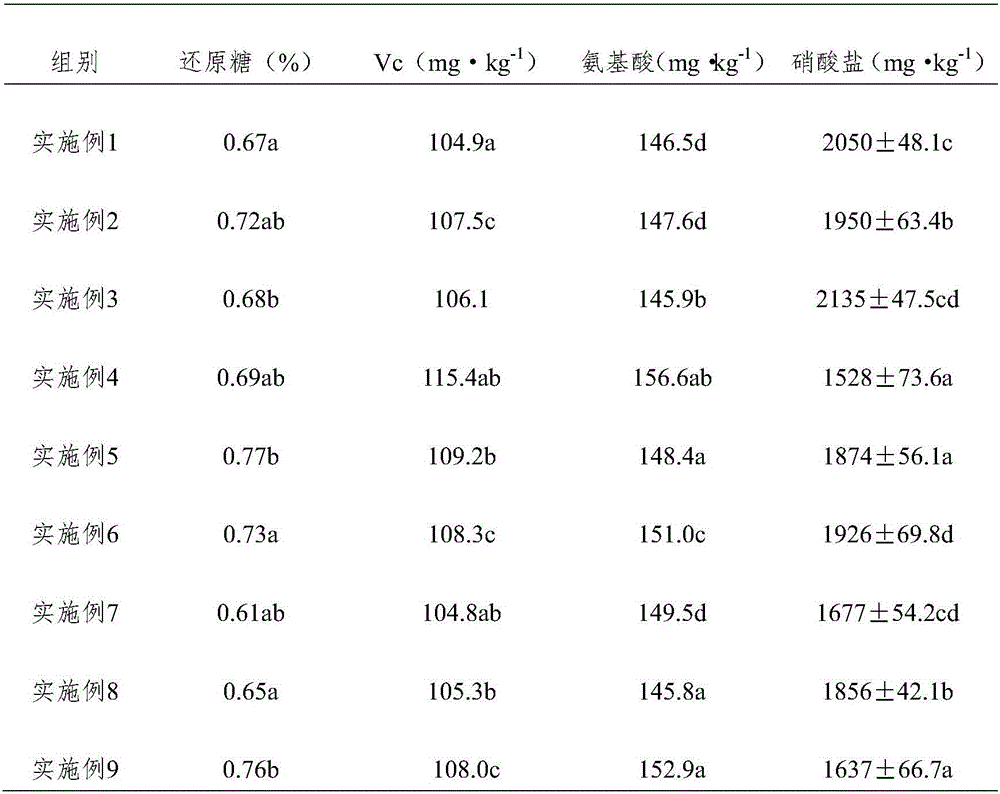

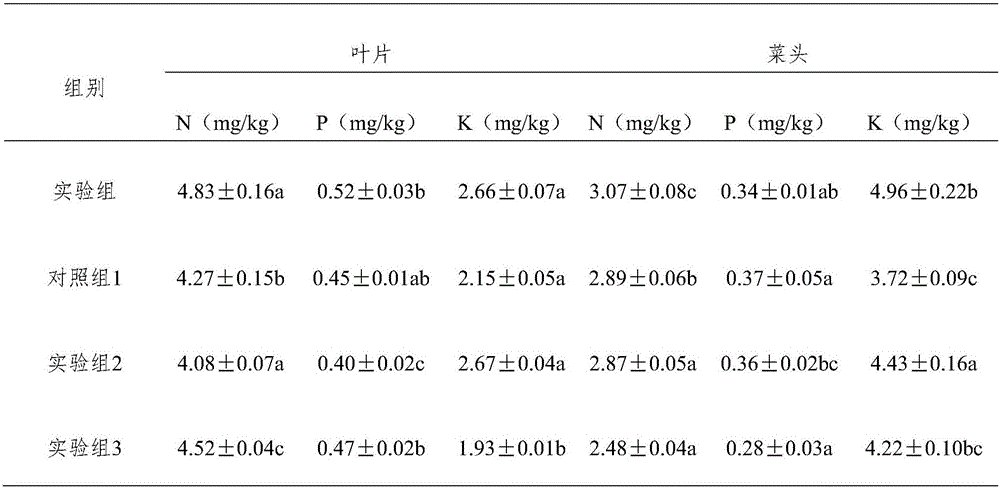

Examples

Embodiment 1

[0019] (1) Add 9kg of amino acid powder into a high-speed mixer, then add 10% dilute sulfuric acid, and process the amino acid powder at a rotating speed of 200r / min;

[0020] (2) Amino acid powder and urea 25kg after processing in step (1), potassium sulfate 15kg, ammonium phosphate 12kg, ammonium thiosulfate 5kg, boric acid 1kg, zinc sulfate 0.1kg, magnesium sulfate 2kg, sodium salicylate 2kg are successively Add it into a sealed reaction kettle, control the temperature at 65-67°C, rotate at 20r / min, and mix well until the element ratio of nitrogen, phosphorus, and potassium in the mixture is 1.1:0.4:0.8;

[0021] (3) Send the materials in step (2) together with 0.5kg of sodium salicylate into the micron pulverizer, driven by the air flow, the materials collide with each other and rub against each other in the middle of the pulverizing cavity of the micron pulverizer to crush the materials Grinding to a particle size of ≤2 μm, packaging to obtain the special fertilizer for k...

Embodiment 2

[0023] (1) Add 4kg of amino acid powder into a high-speed mixer, then add dilute sulfuric acid accounting for 4% of the amino acid powder, and process the amino acid powder under the condition of a rotating speed of 250r / min;

[0024] (2) Amino acid powder and urea 30kg after processing in step (1), potassium sulfate 18kg, ammonium phosphate 16kg, potassium thiosulfate 10kg, boric acid 3kg, zinc sulfate 0.5kg, magnesium sulfate 5kg, sodium salicylate 0.5kg Sequentially add to the sealed reaction kettle, control the temperature at 73-75°C, rotate at 40r / min, and mix thoroughly until the element ratio of nitrogen, phosphorus, and potassium in the mixture is 1.5:0.7:1.3;

[0025] (3) Send the materials in step (2) together with 2kg of sodium salicylate into the micron pulverizer, driven by the airflow, the materials collide with each other and rub against each other in the middle of the pulverizing chamber of the micron pulverizer to pulverize the materials When the particle size...

Embodiment 3

[0027] (1) Add 6kg of amino acid powder into a high-speed mixer, then add 7% dilute sulfuric acid, and process the amino acid powder under the condition of a rotating speed of 230r / min;

[0028] (2) Amino acid powder and urea 27kg after processing in step (1), potassium sulfate 18kg, ammonium phosphate 14kg, calcium thiosulfate 7kg, boric acid 2kg, zinc sulfate 0.4kg, magnesium sulfate 3kg, sodium salicylate 1kg, Add 5kg of bone char, 1kg of calcium sulfide, and 1kg of magnesium sulfide into the sealed reaction kettle in turn, control the temperature at 69-71°C, and rotate at a speed of 30r / min, and mix well until the ratio of nitrogen, phosphorus, and potassium in the mixture is 1.3:0.5 : 1.1;

[0029] (3) Send the materials in step (2) together with 1kg of sodium salicylate into the micron pulverizer, driven by the air flow, the materials collide with each other and rub against each other in the middle of the pulverizer cavity to pulverize the materials When the particle si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com