Method for preparing zirconium oxide ceramic by 3D (Three Dimensional) printing based on photo-curing molding

A technology of zirconia ceramics and ceramic powders, applied in the field of 3D printing, can solve the problems of heavy dependence on molds and the inability to prepare complex and precise structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Dissolve 80g of solute in 70g of solvent and mix to obtain premix 1. After mixing 150g of premix 1, 0.8g of photoinitiator and 1g of dispersant evenly, add 150g of zirconia ceramic powder to the mixing system and mix evenly to obtain the first product 1. In this embodiment, the solute is pentaerythritol diacrylate and trimethylolpropane triacrylate, the solvent is polyethylene glycol 300, and the photoinitiator is 2-hydroxyl-2-methyl-1-phenyl-1-acetone , the dispersant is BYK-9076.

[0040] The first product 1 was ball milled to obtain slurry 1. In this embodiment, the ball milling time is 2 hours, the ball milling medium is zirconia ceramic balls, the shape of the ball milling medium is cylindrical, and the diameter of the ball milling medium is 50 mm.

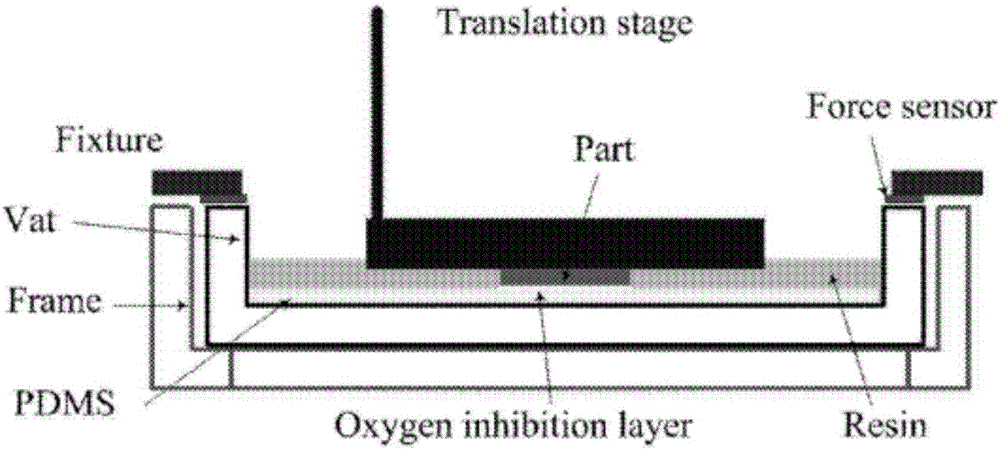

[0041] The slurry 1 is placed in a light curing molding device based on digital light processing (DLP), and the green body 1 is drawn according to the designed ceramic shape through the light curing molding method. ...

Embodiment 2

[0047] 62.5g of solute was dissolved in 87.5g of solvent and mixed to obtain premix 2. After 150g of premix 2, 1g of photoinitiator and 1g of dispersant were mixed uniformly, 225g of zirconia ceramic powder was added to the mixing system and mixed uniformly to obtain the first Product 2. In this example, the solute is 1,6-hexanediol diacrylate, the solvent is n-octanol and polyethylene glycol 300, and the photoinitiator is 2-hydroxy-2-methyl-1-phenyl-1-acetone , the dispersant is BYK-9077.

[0048] The first product 2 was ball milled to obtain slurry 2. In this embodiment, the ball milling time is 3 hours, the ball milling medium is alumina grinding balls, the shape of the ball milling medium is circular, and the diameter of the ball milling medium is 3 mm.

[0049] The slurry 2 is placed in a light-curing molding device based on digital light processing (DLP), and the green body 2 is drawn according to the designed ceramic shape through the light-curing molding method. Amo...

Embodiment 3

[0055] Dissolve 85g of solute in 65g of solvent and mix to obtain premix 3. After mixing 150g of premix 3, 1.5g of photoinitiator and 2g of dispersant, add 225g of zirconia ceramic powder to the mixing system and mix evenly to obtain the first product 3. In this example, the solute is ethoxylated trimethylolpropane triacrylate, the solvent is glycerin and polyethylene glycol 300, and the photoinitiator is 2,2-dimethoxy-1,2-benzophenone. The dispersant is BYK-9076.

[0056] The first product 3 was ball milled to obtain slurry 3. In this embodiment, the ball milling time is 3 hours, the ball milling medium is zirconia grinding balls, the shape of the ball milling medium is cylindrical, and the diameter of the ball milling medium is 3 mm.

[0057] The slurry 3 is placed in a light curing molding device based on digital light processing (DLP), and the green body 3 is drawn according to the designed ceramic shape through the light curing molding method. Among them, the exposure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com