Preparation method of ethylene tar-based porous carbon with narrow aperture distribution

A technology of ethylene tar and porous carbon, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of difficult template removal, complicated operation, high cost, and achieve favorable electrochemical performance, wide range of sources, high cost, etc. The effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of carbonaceous precursor: 10g of ethylene tar was dissolved in 600ml of n-heptane, heated to 120°C, refluxed for 5 hours, filtered, and the filter cake was dried in an oven at 80°C for 2 hours. Take 5 g of the above solid and dissolve it in 35 mL of concentrated sulfuric acid with a mass fraction of 98%, slowly add 15 mL of concentrated nitric acid with a mass fraction of 37%, and react for 60 minutes under stirring at room temperature. The oxidized liquid was transferred to 1L of water, filtered, and dried at 70° C. for 3 hours, and the obtained oxidized product was the precursor of the porous carbon material.

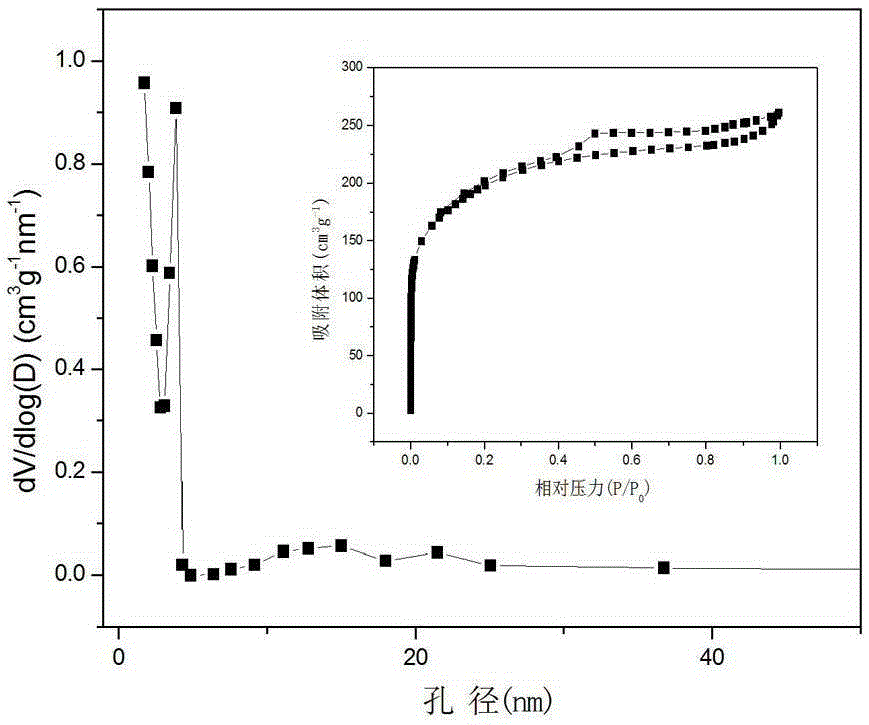

[0030] Preparation of porous carbon: Dissolve 1 g of carbon precursor in 800 mL of 0.34 mol / L sodium hydroxide solution, and drop into 300 mL of 0.3 mol / L magnesium sulfate solution under vigorous stirring. After standing overnight, the supernatant was removed, centrifuged and dried to obtain a co-precipitate of the carbonaceous precursor and magne...

Embodiment 2

[0034] Carbonaceous precursor preparation: The carbonaceous precursor was prepared according to the method described in Example 1.

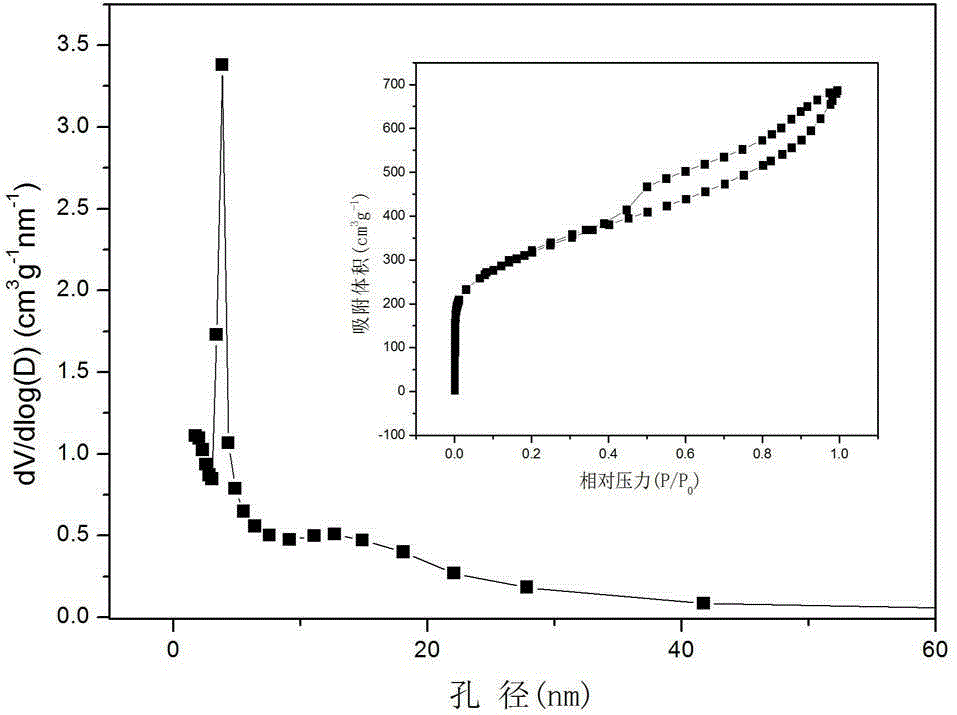

[0035]Porous carbon preparation: Dissolve 1 g of carbon precursor in 500 mL of 0.6 mol / L sodium hydroxide solution, and drop into 650 mL of 0.15 mol / L magnesium nitrate solution under vigorous stirring. Let stand overnight. The supernatant was removed, centrifuged, and dried to obtain a co-precipitate of the carbonaceous precursor and magnesium hydroxide. The above co-precipitate was placed in a tube furnace, and the temperature was raised to 700°C at a rate of 7°C / min in an argon atmosphere, and kept for 1 hour to obtain a mixture of porous carbon and magnesium oxide. The above mixture was washed with 350 mL of 0.25 mol / L nitric acid solution to remove the template agent magnesium oxide, then rinsed with deionized water, and dried at 120° C. for 2 hours to obtain the target product. Test method is with embodiment 1, appended image 3 Its nitr...

Embodiment 3

[0037] Carbonaceous precursor preparation: The carbonaceous precursor was prepared according to the method described in Example 1.

[0038] Porous carbon preparation: Dissolve 1 g of carbon precursor in 300 mL of potassium hydroxide solution with a concentration of 1 mol / L, and add dropwise 2 L of magnesium chloride solution with a concentration of 0.05 mol / L under vigorous stirring. Let stand overnight. The supernatant was removed, centrifuged, and dried to obtain a co-precipitate of the carbonaceous precursor and magnesium hydroxide. The above co-precipitate was placed in a tube furnace, and the temperature was raised to 800°C at a rate of 7°C / min in an argon atmosphere, and kept for 2 hours to obtain a mixture of porous carbon and magnesium oxide. The above mixture was washed with 250 mL of 1 mol / L hydrochloric acid solution to remove the template agent magnesium oxide, then rinsed with deionized water, and dried at 120° C. for 2 hours to obtain the target product. Test m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com