A multi-coated biodegradable metal stent and its preparation method

A metal stent and multi-coating technology, which is applied in the field of medical devices, can solve the problems of uncontrollable service life and curative effect of stents, uncontrollable degradation time, and complicated manufacturing process of magnesium stents, and achieves long service life, strong supporting force, and prevention of restenosis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

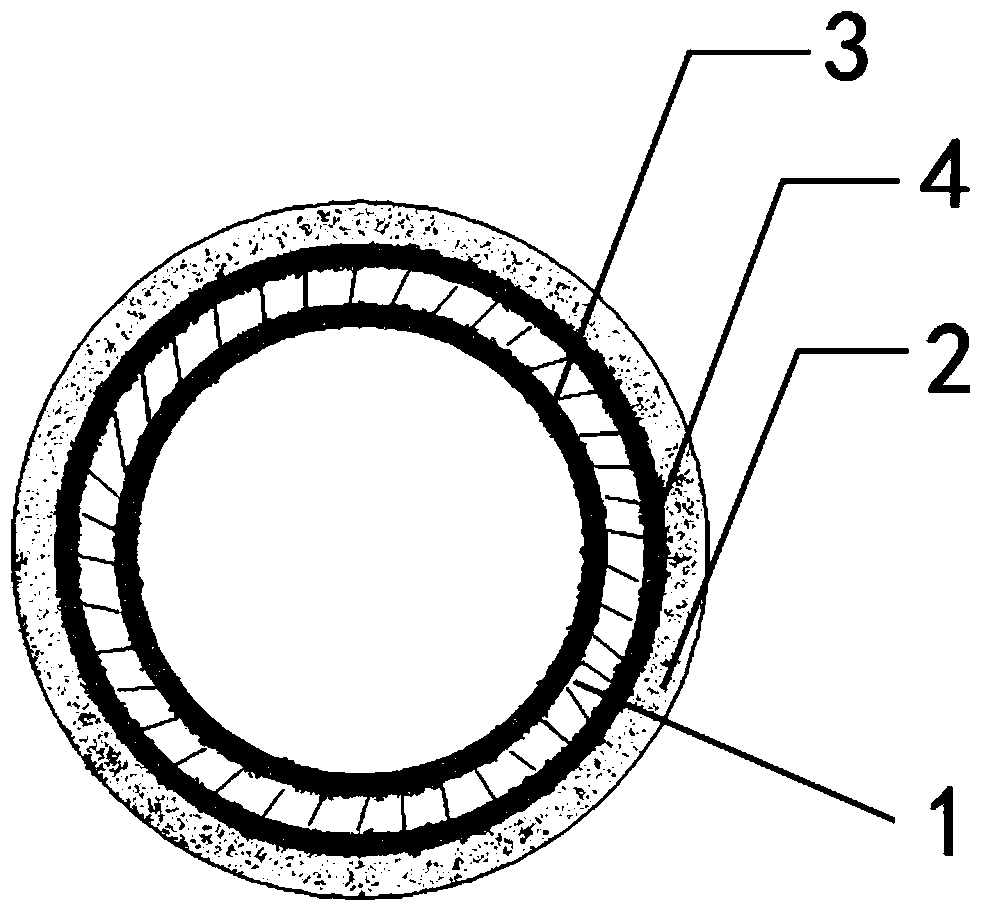

[0053] Such as figure 1 As shown, it is a multi-coated biodegradable metal stent of the present invention,

[0054] It includes: a stent body 1, a drug coating 2, a first temperature control coating 3 and a second temperature control coating 4; the inner surface of the stent body 1 is provided with a first temperature control coating 3, and the outer surface is provided with a second temperature control coating. Temperature coating 4; The drug coating 2 is arranged on the outer surface of the second temperature control coating 4;

[0055] The bracket body 1 is made of pure magnesium;

[0056] The first temperature-controlling coating 3 and the second temperature-controlling coating 4 are degradable polymer layers with blood-cooling, antipyretic and temperature-controlling molecules;

[0057] The drug coating 2 is a composite degradable drug coating with drugs for inhibiting intimal hyperplasia, PDLLA and PLLA.

[0058] Preparation Process:

[0059] The high-purity magnesiu...

Embodiment 2

[0071] Such as figure 1 As shown, it is a multi-coated biodegradable metal stent of the present invention,

[0072] It includes: a stent body 1, a drug coating 2, a first temperature control coating 3 and a second temperature control coating 4; the inner surface of the stent body 1 is provided with a first temperature control coating 3, and the outer surface is provided with a second temperature control coating. Temperature coating 4; The drug coating 2 is arranged on the outer surface of the second temperature control coating 4;

[0073] The bracket body 1 is made of magnesium alloy;

[0074] The first temperature-controlling coating 3 and the second temperature-controlling coating 4 are degradable polymer layers with blood-cooling, antipyretic and temperature-controlling molecules;

[0075] The drug coating 2 is a composite degradable drug coating with drugs for inhibiting intimal hyperplasia, PDLLA and PLLA.

[0076] Preparation Process:

[0077] The magnesium alloy tub...

Embodiment 3

[0090] With embodiment 1, difference is:

[0091] The thickness of the stent body is 90 μm;

[0092] The thickness of the first temperature control coating is 10 μm;

[0093] The thickness of the second temperature control coating is 2 μm;

[0094] The thickness of the drug coating is 5 μm;

[0095] The degradable polymer with blood-cooling, antipyretic and temperature-controlling molecules is a mixed solution of acetaminophen, polyglycolic acid, polylactic acid and polyglycolic acid copolymer (the mixing ratio is 0.5:0.5:1:1).

[0096] The results of the stent test were similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com