Preparation method for isolated needle point with housing layers wrapped in dual manner

A shell and needle tip technology, applied in the field of scanning probes, can solve problems such as needle tip surface contamination, and achieve the effects of simple preparation method, oxidation prevention, and good universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

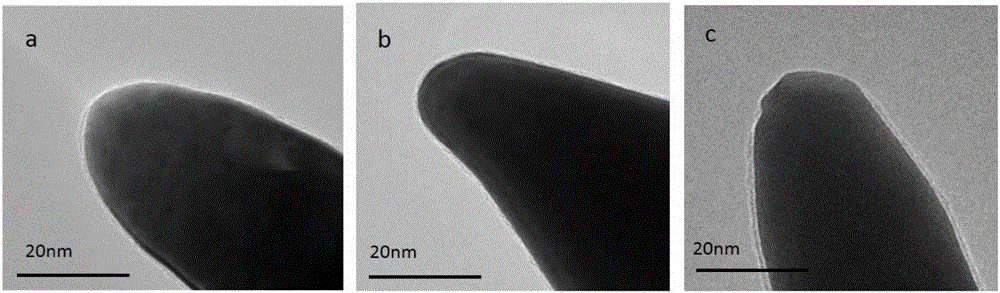

[0028] Example 1: Specific steps of coating 2nm silicon dioxide, aluminum oxide and titanium dioxide. Insert the etched gold needle tip into the special stainless steel base, and then put it into the preheated to 160° (SiO 2 ), 160°(Al 2 o 3 ), 70°(TiO 2 ) into the reaction chamber of the atomic layer deposition system, alternately feed two pulsed silicon sources (or aluminum source, titanium source) and a pulsed water source, and feed high-purity nitrogen for a certain period of time after the source and water source are pulsed. , the source bottle temperature is silicon source (25°), aluminum source (20°), titanium source (20°), water source (25°), ① deposited silica: silicon source pulse time 0.2s, high-purity nitrogen blowing Sweeping for 5s, water source pulse time 0.1s, high-purity nitrogen purging for 5s, 25 cycles can deposit silicon dioxide with a thickness of 2nm. ② Deposition of aluminum oxide: aluminum source pulse time 0.1s, high-purity nitrogen purge 5s, wate...

Embodiment 2

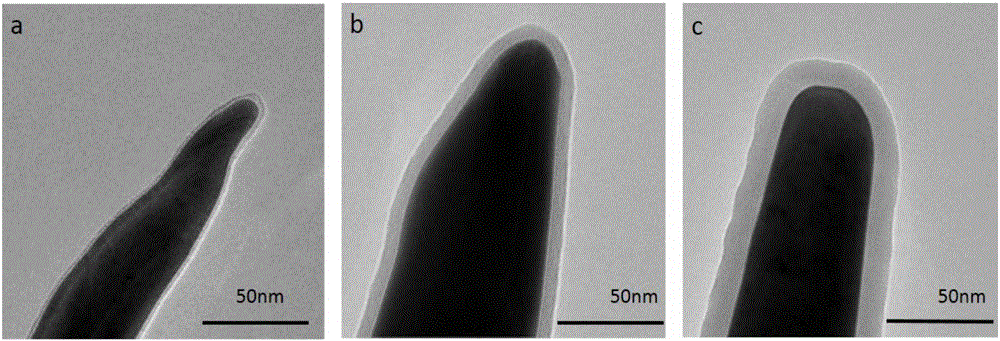

[0029] Example 2: Specific steps of coating 5, 10, 20 nm titanium dioxide. Insert the etched gold needle tip into the special stainless steel base, and then put it into the reaction chamber of the atomic layer deposition system preheated to 70°, alternately feed two pulsed titanium sources and one pulsed water source, the titanium source After pulsing with water source, high-purity nitrogen is flushed for a certain period of time. The temperature of the titanium bottle is set to 20°, the temperature of the water source is 25°, the pulse time of the titanium source is 0.1s, the high-purity nitrogen is purged for 2s, the pulse time of the water source is 0.1s, and the high Purging pure nitrogen for 4s, depositing 50, 134, and 256 cycles respectively can deposit titanium dioxide with a thickness of 5, 10, and 20 nm. Stick the prepared needle tip on the copper ring, and take a high-magnification transmission electron microscope to obtain figure 2 Figure a in figure 2 Figure b ...

Embodiment 3

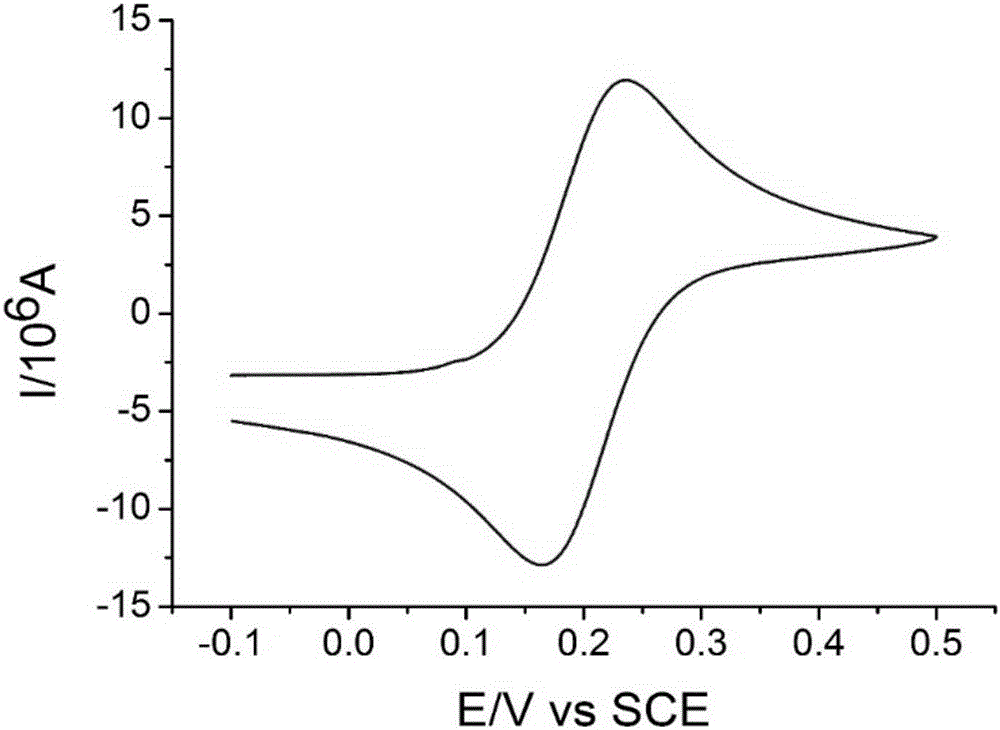

[0030] Example 3: Electrochemical cyclic voltammetry was performed on a gold needle tip double-coated with a 2nm silica shell layer and polymethylstyrene hot melt adhesive. The CHI electrochemical workstation used for electrochemical testing is in the electrolytic cell of the single-chamber three-electrode system. The counter electrode is a platinum wire, the reference electrode is a saturated calomel electrode, and the working electrode is a gold needle tip and a double-coated gold needle tip. Interval: -0.1~0.5V, sampling interval: 0.0001V, scanning speed: 5mV s -1 , at 10mM K 3 Fe(CN) 6 Cyclic voltammetry scanning was carried out in the electrolyte solution of +0.5M KCl to obtain image 3 and Figure 4 . The cyclic voltammogram of the gold tip ( image 3 ) peak current in the microampere level, while the cyclic voltammogram of the double-coated gold tip ( Figure 4 ) presents a typical "S-shaped curve" of micro-nano electrodes, and the steady-state limiting current is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com