Small and medium size boiling type ready-packaged organic carrier heating furnace

An organic carrier, boiling technology, used in lighting and heating equipment, combined devices, gas treatment, etc., can solve the problems of insufficient exhaust gas, increased production costs of enterprises, high oxygen content in the furnace, and reduce the heat emission temperature. , the effect of reducing production costs and reducing emissions and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

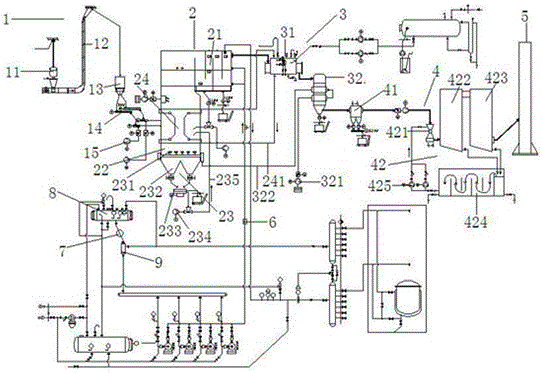

[0032] It is estimated that the heat output is 8 million kcal. A feed auger 14 is set between the feed silo 13 and the furnace 2, and the biomass fuel is sent to the feed silo through the crane 11 and the chain lift 12 to avoid fuel The discharge port of the feed silo 13 is blocked. The two sides of the feed silo 13 are provided with air hammers. The air hammers move relative to each other in a pulse type to keep the discharge port unobstructed. The fuel is sent into the furnace 2 through the feed auger 14, and a fuel blower 15 is provided under the feed auger 14. The blower blows the lighter fuel into the air when it enters the furnace 2, so that the fuel can be in the air. Combustion avoids the problem of uneven temperature of the furnace 2 caused by fuel deposits at the bottom of the furnace 2, and can also ensure the adequacy of fuel combustion.

[0033] Heavier fuel sinks and burns in the fuel combustion zone 22 at the bottom of the furnace 2. In addition to the fuel combust...

Embodiment 2

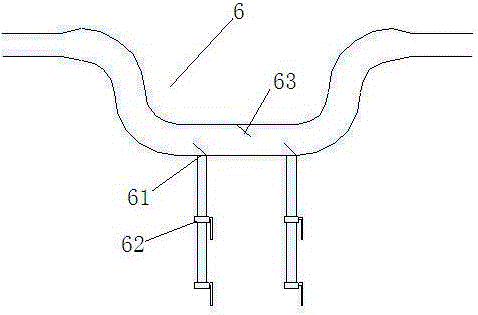

[0037] Such as figure 2 The sludge separator 6 shown is arranged between the hot oil heater 21 and the oil inlet and outlet device. The sludge separator 6 has a concave structure, and the bottom of the sludge separator 6 is provided with a sewage port 61, the sewage port 61 and the sewage valve 62 The pipe diameter is 40% larger than that of the oil pipe. The upper and lower walls of the sludge separator 6 are respectively provided with mud baffle plates 63, wherein the upper wall mud baffle plate 63 forms an angle of 130° with the oil inlet direction; The mud baffle plate 63 forms an angle of 40° with the oil inlet direction; the radial cross-sectional area of the mud baffle plate 63 is 1 / 3 of the radial cross-sectional area of the inner wall of the sludge separator 6; the oil of the hot oil heater 21 passes through the oil pipe through the sludge separation The pipe diameter of the sludge separator 6 is 40% larger than the pipe diameter of the oil pipe, which increases th...

Embodiment 3

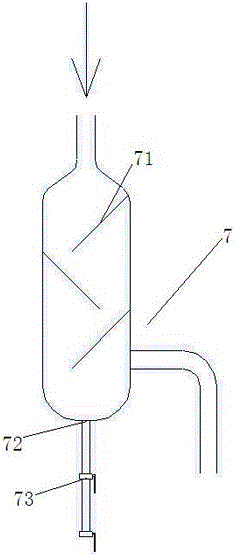

[0039] Such as image 3 The oil-water separator 7 shown is arranged in the oil inlet and outlet device, the oil inlet and outlet device includes an expansion tank 8, an oil pressure balance tank 9, and an oil and water separator 7 is provided between the expansion tank 8 and the oil pressure balance tank 9. The oil-water separator 7 is a bottle-shaped structure with a blocking plate 71 inside which forms an angle of 130° with the oil inlet direction. The radial section area of the blocking plate 71 is the radial section of the inner wall of the oil-water separator 7 2 / 3 of the area, the bottom of the oil-water separator 7 is provided with an oil discharge port 72, which is connected to the oil discharge valve 73; the heat conduction oil discharged from the oil pressure balance tank 9 first enters the oil-water separator 7, and the oil-water separator 7 The weight of water, oil residue, and oil sludge is deposited at the bottom of the oil-water separator 7 to prevent them from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com