Stamping servo compensation system and working process thereof

A compensation system and die punching technology, applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, mechanical equipment, etc., can solve problems such as cracks, and achieve the effects of low thermal equilibrium temperature, significant energy saving effect and long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

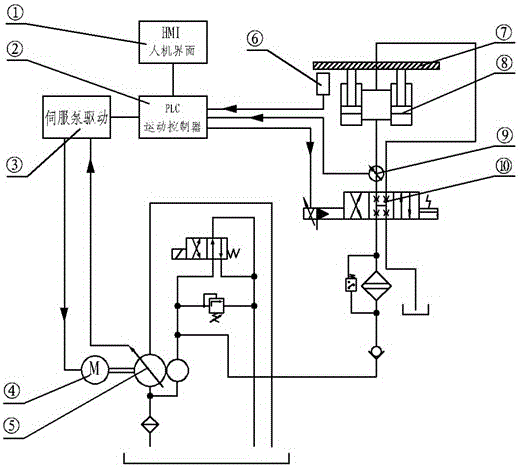

[0018] Such as figure 1 As shown: the present invention is composed of a human-computer interaction interface, a PLC motion controller, a hydraulic servo pump system, a servo proportional valve, a position sensor, a pressure sensor and other electrical control components, a hydraulic cylinder, and a punching fixed template;

[0019] The PLC motion controller is connected to a servo pump drive all the way, the servo pump drive is connected to a servo pump, and the servo pump is connected to a pressure sensor one;

[0020] The other path of the PLC motion controller is connected to the servo proportional valve controlled by it, and is connected with a pressure sensor 2 and a displacement sensor, and the displacement sensor is used to detect the position of the die punching fixed template.

[0021] The working process of the punching servo compensation system is carried out according to the following steps:

[0022] 1) System power-on initialization;

[0023] 2) pass human-ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com