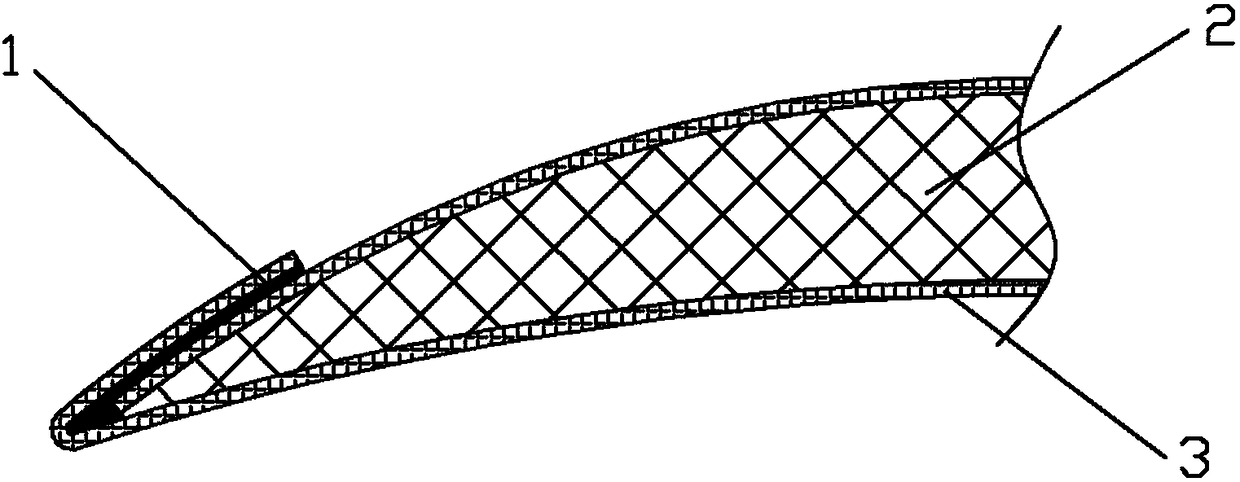

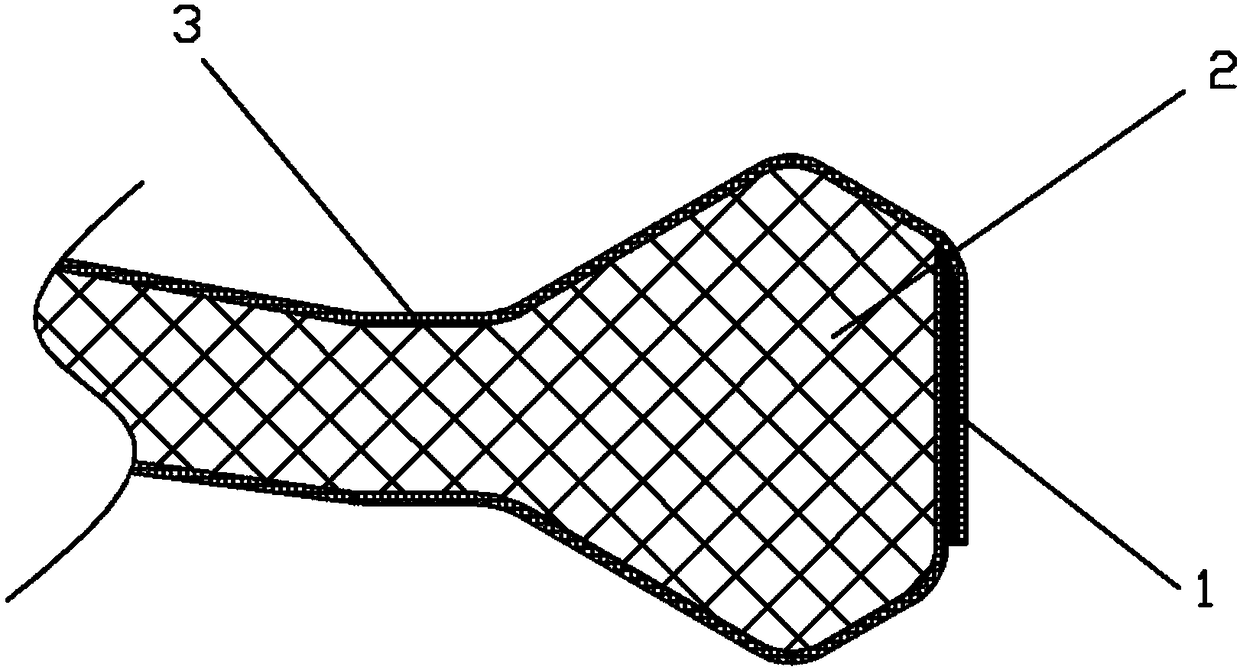

Composite compressor fan blade with integral metal cladding

A metal cladding and composite material technology, which is applied to liquid fuel engines, components of pumping devices for elastic fluids, mechanical equipment, etc. Three-dimensional weaving is difficult and other problems, to achieve the effect of excellent erosion resistance, avoid cracks or even breakage, and excellent impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The first step is to calculate the size and shape of the expanded blank of the blade model in dynaform, and then cut out two corresponding TA2 plates after appropriately increasing the margin, and put them into the stamping die with the shape of the upper and lower skin surfaces of the blade respectively , forming to the desired surface shape;

[0041] In the second step, the excess skin of the formed upper and lower titanium plates is cut off, and degreasing, pickling and sodium hydroxide anodizing (sandblasting) treatment are carried out in sequence. The composition of the anodizing electrolyte is: NaOH 300g / L, Tart 65g / L, EDTA 30g / L, Na2SiO3 6g / L, the voltage is 10V, the electrolysis time is 10min, and the electrolysis temperature is 35°C;

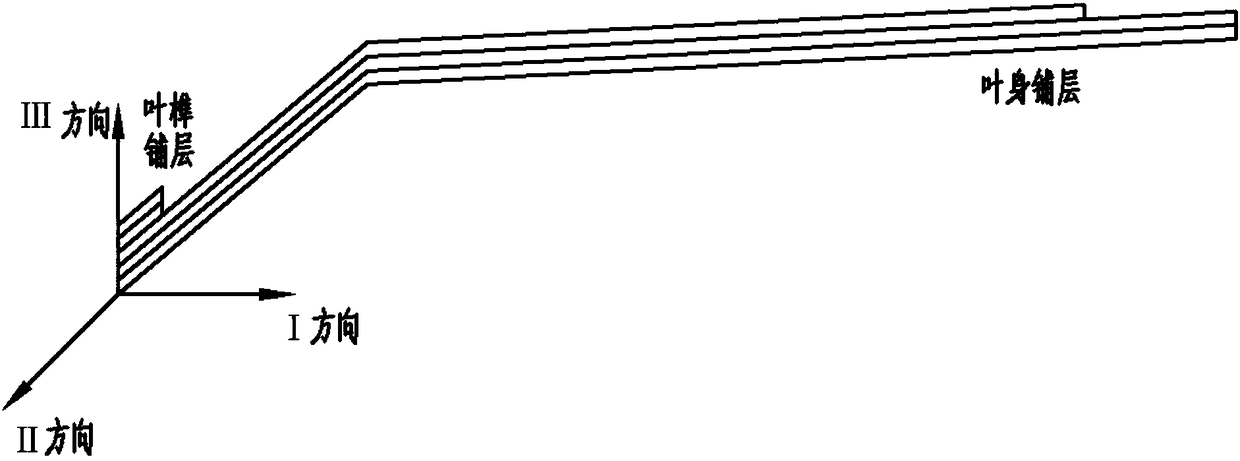

[0042] The third step is to calculate the number of epoxy resin prepregs with a thickness of 0.125mm required for each part and the shape and size of each layer according to the intercalation laying method, and cut them in place ...

Embodiment 2

[0050] The first step is to calculate the size and shape of the expanded blank of the blade model in dynaform, and then cut out two corresponding TA2 plates after appropriately increasing the margin, and put them into the stamping die with the shape of the upper and lower skin surfaces of the blade respectively , forming to the desired surface shape;

[0051] In the second step, the excess skin of the formed upper and lower titanium plates is cut off, and degreasing, pickling and sodium hydroxide anodizing (sandblasting) treatment are carried out in sequence. The composition of the anodizing electrolyte is: NaOH 300g / L, Tart 65g / L, EDTA 30g / L, Na2SiO3 6g / L, the voltage is 10V, the electrolysis time is 10min, and the electrolysis temperature is 35°C;

[0052] The third step is to calculate the number of polyetherether copper prepregs with a thickness of 0.125mm required for each part and the shape and size of each layer according to the intercalation laying method, and cut them...

Embodiment 3

[0060] The first step is to calculate the size and shape of the expanded blank of the blade model in dynaform, and then cut out two corresponding TA2 plates after appropriately increasing the margin, and put them into the progressive forming machine tool for positioning and fastening, according to the required surface Write the NC program and input the shape, the indenter starts to move the knife, and forms to the required surface shape;

[0061] In the second step, the excess skin of the formed upper and lower titanium plates is cut off, and degreasing, pickling and sodium hydroxide anodizing (sandblasting) treatment are carried out in sequence. The composition of the anodizing electrolyte is: NaOH 300g / L, Tart 65g / L, EDTA 30g / L, Na2SiO3 6g / L, the voltage is 10V, the electrolysis time is 10min, and the electrolysis temperature is 35°C;

[0062] The third step is to calculate the number of epoxy resin prepregs with a thickness of 0.125mm required for each part and the shape an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com