A preparation method of water-soluble filter paper cellulose micelles with photoresponsive properties

A cellulose and water-soluble technology, which is applied in the fields of polymer materials and biomedical engineering, can solve the problems of high chemical inertness and poor solubility, and achieve the effects of wide application prospects, solubility changes, and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

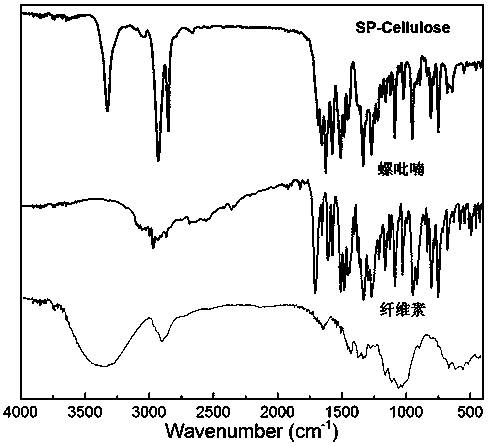

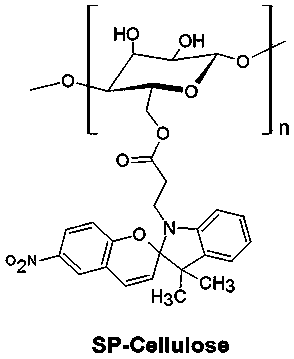

Method used

Image

Examples

Embodiment 1

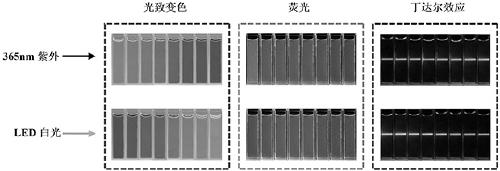

[0019] Break 3g of cellulose filter paper into a pulp in tetrahydrofuran, add carboxyl-containing spiropyran with a mass ratio of 1:4 to the filter paper cellulose, and 4 -Dimethylaminopiperidine, and cooled to 0°C, then dropwise added dicyclohexylcarbodiimide solution dissolved in tetrahydrofuran at a molar ratio of 1.2:1 to carboxyl-containing spiropyran, and stirred at constant temperature for 2 hours, Continue to react for 48 hours at 25°C under the protection of nitrogen to complete; filter and wash; collect all the filtrate and distill under reduced pressure to obtain the crude product; after dissolving and filtering in ethanol, add a large amount of deionized water to the filtrate to filter to remove impurities to obtain a pink solid, after vacuum drying, Dissolve the obtained spiropyran modified filter paper cellulose in ethanol to configure a concentration of 3.8×10 -1 g / L solution, irradiate the prepared solution under 365nm ultraviolet light for 6 minutes. Then in ...

Embodiment 2

[0021] Break 3g of cellulose filter paper into pulp in dichloromethane, add carboxyl-containing spiropyran in a mass ratio of 1:3 to filter paper cellulose, and carboxyl-containing spiropyran in a molar ratio of 1:4 4-dimethylaminopiperidine, and cooled to 5°C, then dropwise added dicyclohexylcarbodiimide solution dissolved in dichloromethane with a molar ratio of 1.1:1 to carboxyl-containing spiropyran, and stirred at constant temperature After 2 hours, continue the reaction at 20°C under the protection of nitrogen for 24 hours; filter and wash; collect all the filtrate and distill under reduced pressure to obtain the crude product; after dissolving and filtering in ethanol, add a large amount of distilled water to the filtrate to filter to remove impurities to obtain a pink solid, and vacuum dry Finally, the obtained spiropyran-modified filter paper cellulose was dissolved in methanol to form a solution with a concentration of 1 g / L, and the prepared solution was irradiated w...

Embodiment 3

[0023] Break 3 g of cellulose filter paper into pulp in chloroform, add carboxyl-containing spiropyran in a mass ratio of 1:3 to filter paper cellulose, and 4 -Dimethylaminopiperidine, and cooled to 10°C, then dropwise added dicyclohexylcarbodiimide solution dissolved in chloroform with a molar ratio of 1.2:1 to carboxyl-containing spiropyran, and stirred at constant temperature for 3 hours, Continue to react for 48 hours at 25°C under the protection of nitrogen to complete; filter and wash; collect all the filtrate and distill under reduced pressure to obtain the crude product; after dissolving and filtering in methanol, add a large amount of distilled water to the filtrate and filter to remove impurities to obtain a pink solid, which will be obtained after vacuum drying. The spiropyran modified filter paper cellulose was dissolved in ethanol to form a concentration of 8×10 -1 g / L solution, irradiate the prepared solution under 365nm ultraviolet light for 8 minutes. Then in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com