A kind of yttrium-containing amorphous magnesium alloy material and preparation method thereof

A magnesium alloy and amorphous technology, applied in the field of yttrium-containing amorphous alloy materials and its preparation, can solve the problem that the corrosion resistance of medical magnesium alloy cannot meet the growth and recovery period of orthopedics, and achieve good biocompatibility and superior corrosion resistance Performance, the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

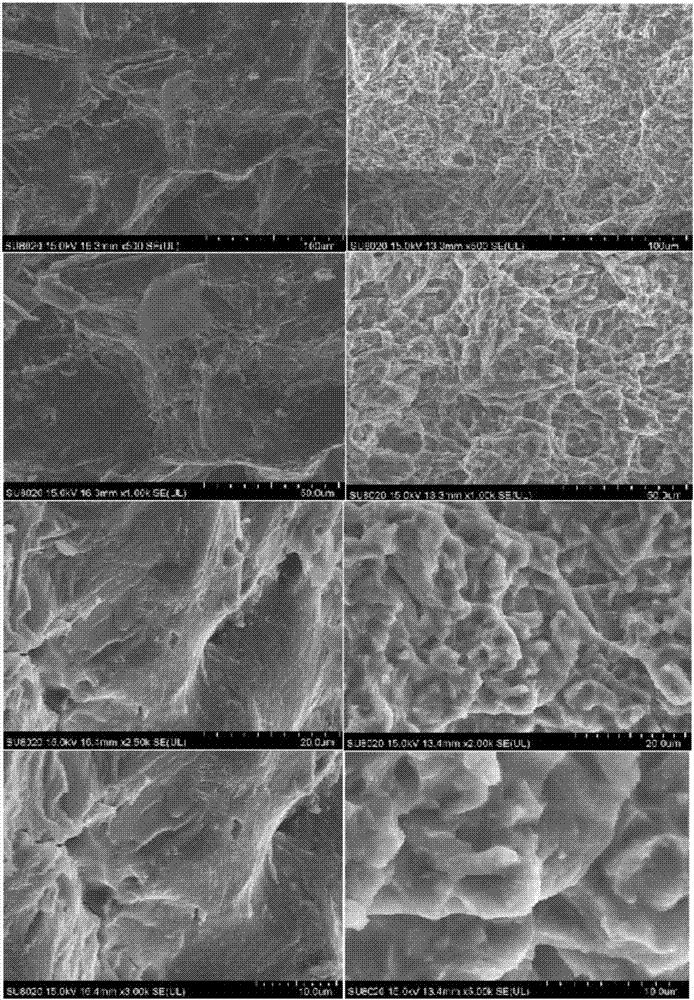

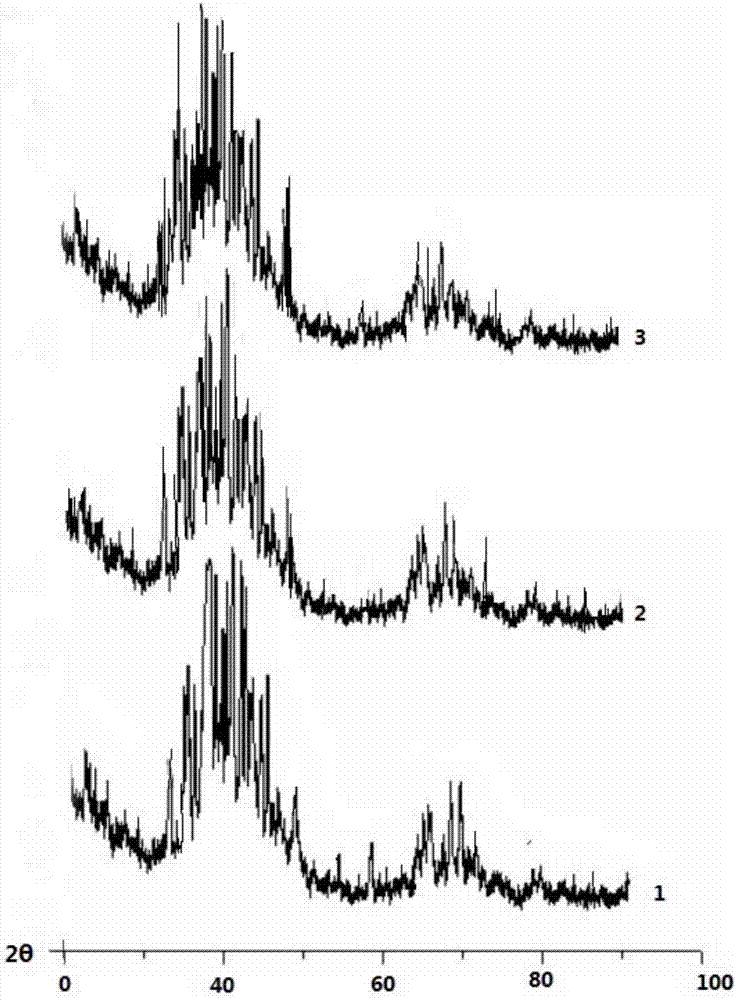

Embodiment 1

[0032] A yttrium-containing amorphous magnesium alloy material is characterized in that the alloy structure is amorphous and is composed of the following components by mass percentage: 1.5% Y, 2% Zn, 0.5% Ca, and the balance is magnesium and impurity elements introduced during the micro-preparation process.

[0033]The preparation method of the material specifically includes:

[0034] 1) Preparation of yttrium-containing cast magnesium alloy master ingot:

[0035] Under the condition of 800-810°C, add KCl:NaCl=1:1 into the crucible as a covering agent, and distribute it into the crucible according to the weight ratio of 1.5% Y, 2% Zn, 0.5% Ca, and the balance is magnesium. Batch adding ingots:

[0036] First add small pieces of magnesium ingots under the condition of 740-760°C and keep it warm for 10 minutes.

[0037] Add fragmented yttrium ingot at 715-725°C and keep it warm for 1h.

[0038] Then add magnesium ingots containing zinc and calcium at 650-690°C, keep warm unt...

Embodiment 2

[0042] A yttrium-containing amorphous magnesium alloy material is characterized in that the alloy structure is amorphous and is composed of the following components by mass percent: 3% Y, 1.5% Zn, 1% Ca, and the balance is magnesium and impurity elements introduced during the micro-preparation process.

[0043] The preparation method of the material specifically includes:

[0044] 1) Preparation of yttrium-containing cast magnesium alloy master ingot:

[0045] Under the condition of 800-810°C, add KCl:NaCl=1:1 into the crucible as a covering agent, and distribute it into the crucible according to the weight ratio of 3% Y, 1.5% Zn, 1% Ca, and the balance is magnesium. Batch adding ingots:

[0046] First add small pieces of magnesium ingots under the condition of 740-760 ℃, and keep it warm for 8 minutes.

[0047] Add fragmented yttrium ingot at 715-725°C and keep it warm for 1.5h.

[0048] Then add magnesium ingots containing zinc and calcium at 650-690°C and keep warm unti...

Embodiment 3

[0052] A yttrium-containing amorphous magnesium alloy material is characterized in that the alloy structure is amorphous and is composed of the following components by mass percentage: 6% Y, 0.5% Zn, 1.5% Ca, and the balance is magnesium and Impurity elements introduced during trace preparation.

[0053] The preparation method of this material is the same as the preparation method of Example 2 except that the raw material ratio is 6% Y, 0.5% Zn, 1.5% Ca and the balance is magnesium, and the ejection pressure is 0.02.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com