Iron smelting process achieving effective and cyclic utilization of stock gas of blast furnace

A furnace top gas and blast furnace technology, applied in the field of new energy saving and emission reduction technology and blast furnace ironmaking process, can solve the problems of increased energy consumption in sintering process, secondary pollution, low quality of cooling exhaust gas, etc., so as to improve smelting conditions and reduce blast furnace The effect of energy consumption, energy saving and emission reduction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

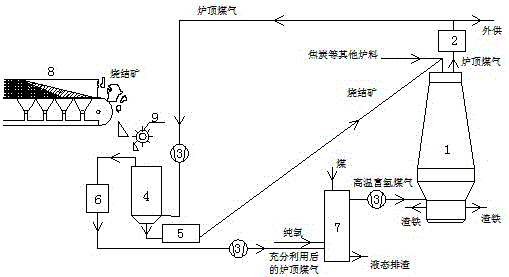

[0028] After the blast furnace top gas is dedusted, it is transported to the sintering workshop through the gas pipeline. After pressurization, the sinter is sprayed from the bottom for pre-reduction and cooling of the shaft furnace, forming a convective movement with the falling high-temperature sinter, reducing the sinter and cooling down at the same time. The pre-reduced and cooled sinter is discharged from the shaft furnace, sintered into granules, screened and classified by the screening device, and the qualified sinter is transported to the top charging equipment of the blast furnace by a belt conveyor. The gas discharged from the top of the sinter pre-reduction and cooling shaft furnace passes through the waste heat recovery device to recover and utilize its heat. After recovering heat, the gas is pressurized by the pressurizing device, and then injected into the gas-making and reforming furnace together with pure oxygen. After gas-making and reforming, high-temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com