Lipase immobilization method

A technology of lipase and fusion protein, applied in biochemical equipment and methods, enzymes, immobilized on/in organic carriers, etc., can solve problems such as high production cost, difficulty in expanding production scale, and limited production capacity, and achieve Effects of increasing production volume, improving reusability, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Construction of rice transformation T-DNA vector pCAMB1300-GT1-CalB-CBM

[0024] The lipase amino acid sequence encoding gene (amino acid sequence SEQ ID NO.1), the protein linking peptide encoding gene (amino acid sequence SEQ ID NO.2) and the chitosan binding domain amino acid sequence encoding gene (amino acid sequence SEQ ID NO.3) were sequentially Linked into a lipase fusion gene, artificially synthesized by Shanghai Shenggong Company (Shanghai, China) to contain the nucleotide of the lipase fusion gene and the 35S terminator, its sequence is SEQ ID NO: 4 (wherein 1-957 encodes lipase, 958-1077bp encodes the connecting peptide, 1078-1863bp encodes the chitosan binding domain, and 1864-2047bp is the terminator sequence).

[0025] Using PCR primer GT1-F (5' AAGCTT GAGATTCATCAATATGAGAAAAC, the underline is the HindⅢ site); and GT1-R (5' TCTAGA CTGGGCTAGGGAGCCATCGCAC, the underline is the Xba I site) from rice (Oryza sativajaponica L.) genomic DNA amplif...

Embodiment 2

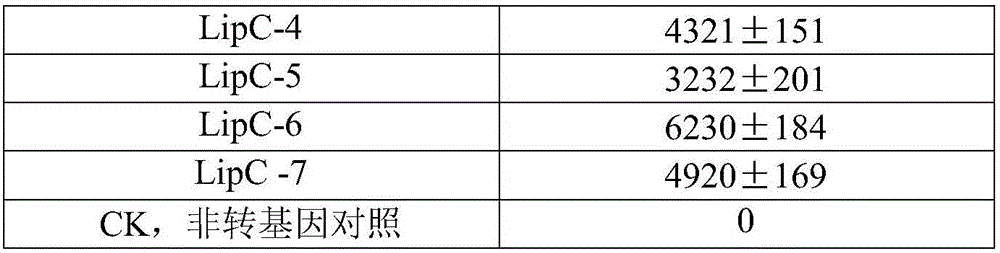

[0028] Example 2: Obtaining of transgenic rice containing lipase fusion gene

[0029] The method for obtaining the transgenic rice is to use the Agrobacterium infection method, and transform according to the method and medium formula reported by Zhao et al. (Agricultural Sciences in China, 2011, 10(9):1307-1312). The specific steps are: . The mature and plump "Xiushui 134" seeds were dehulled, and callus was induced as transformation materials. Get the Agrobacterium containing the plant transformation vector pCAMB1300-GT1-CalB-CBM obtained in Example 1 and streak culture on the YEP plate containing 50 mg / mL kana resistance, pick a single colony and inoculate it into the YEP liquid medium, and cultivate it at 28°C to OD 660 is 0.5, obtain the Agrobacterium liquid, and prepare the Agrobacterium for transformation. Put the rice callus to be transformed into OD 660 0.5 in the Agrobacterium liquid containing 40mg / mL acetosyringone, shake on a horizontal shaker at 120rpm for 1 ho...

Embodiment 3

[0030] Example 3: Extraction of lipase fusion protein in rice seeds

[0031] The transgenic rice seeds obtained in Example 2 were dehulled, and 5 g of the dehulled seeds were homogenized with 100 ml of Tri-HCL buffer solution of 20 mM pH8.0. After the homogenization, they were shaken and extracted for 2 hours, and the supernatant was taken after standing liquid, the supernatant was filtered through a 300-500 mesh filter, and the obtained filtrate (ie lipase fusion protein solution) was used for lipase immobilization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com