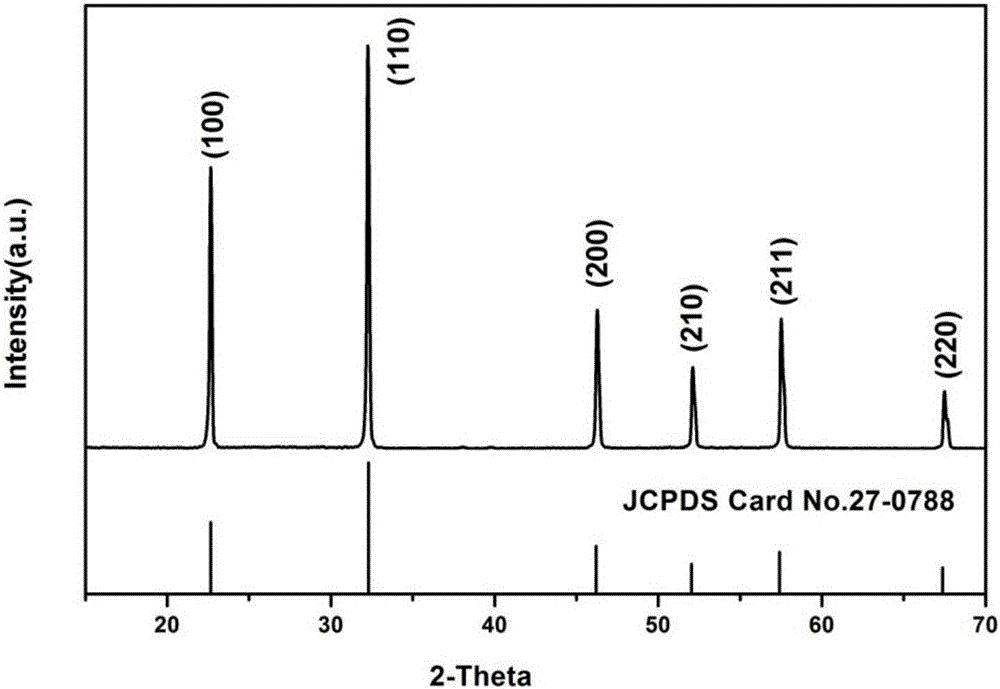

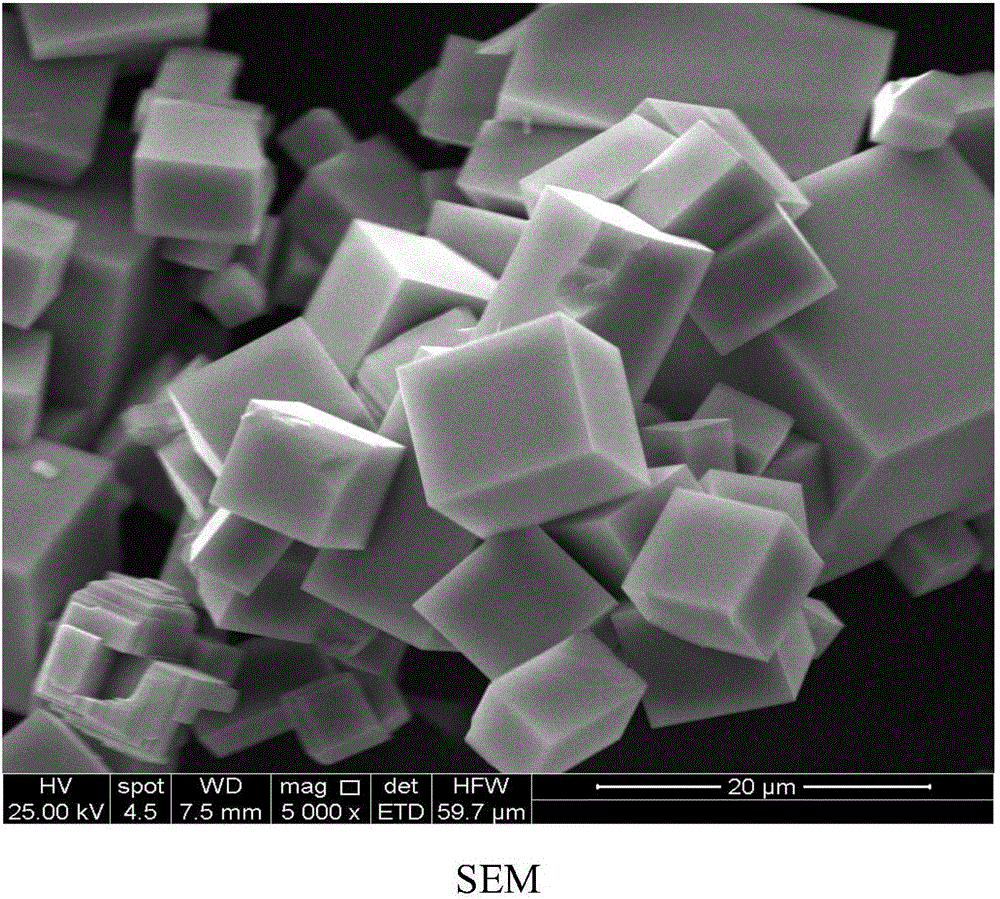

Cubic strontium sodium niobate red fluorescent powder and preparation method thereof

A technology of red fluorescent powder and sodium strontium niobate, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of high sintering temperature, uneven particles, low color purity, etc., and achieve high powder purity and uniform particle size , good effect of crystallization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) with SrCO 3 and Nb 2 o 5 As raw materials, weigh them respectively according to the molar ratio of 0.825:1, place the weighed raw materials in an agate mortar, grind them at room temperature for 2 hours to make them evenly mixed before use;

[0024] 2) Let SrCO 3 and Nb 2 o 5 The total mass of M (M = M SrCO3 +M Nb2O5 ), the mass of NaCl is m, and NaCl is weighed as a molten salt according to the ratio of M:m=1:5, and it is mixed with the raw material obtained in step 1), and the mixture is fully ground at room temperature for 2 hours to obtain a mixed powder;

[0025] 3) Place the mixed powder obtained in step 2 in Al 2 o 3 Al in the crucible 2 o 3 cover covered.

[0026] 4) Al 2 o 3 Put the crucible in the furnace, start from room temperature, raise the temperature to 600°C at a rate of 3°C / min, then raise the temperature to 1150°C at a rate of 5°C / min, cool down to 300°C at a rate of 2°C / min after holding for 9 hours, and then Take it out with the fur...

Embodiment 2

[0031] 1) with SrCO 3 and Nb 2 o 5 As raw materials, weigh them respectively according to the molar ratio of 0.75:1, place the weighed raw materials in an agate mortar, grind them at room temperature for 2 hours to make them evenly mixed before use;

[0032] 2) Let SrCO 3 and Nb 2 o 5 The total mass of M (M = M SrCO3 +M Nb2O5 ), the mass of NaCl is m, and NaCl is weighed as a molten salt according to the ratio of M:m=1:3, and mixed with the raw material obtained in step 1), and the mixture is fully ground at room temperature for 2 hours to obtain a mixed powder;

[0033] 3) Place the mixed powder obtained in step 2 in Al 2 o 3 Al in the crucible 2 o 3 cover covered.

[0034] 4) Al 2 o 3 Place the crucible in the furnace, start from room temperature, raise the temperature to 600°C at a rate of 3°C / min, then raise the temperature to 1100°C at a rate of 5°C / min, cool down to 300°C at a rate of 2°C / min after holding for 6 hours, and then Take it out with the furnace ...

Embodiment 3

[0037] 1) with SrCO 3 and Nb 2 o 5 As raw materials, weigh them separately according to the molar ratio of 0.675:1, place the weighed raw materials in an agate mortar, grind them at room temperature for 2 hours to make them evenly mixed and then set aside;

[0038] 2) Let SrCO 3 and Nb 2 o 5 The total mass of M (M = M SrCO3 +M Nb2O5), the mass of NaCl is m, and NaCl is weighed as a molten salt according to the ratio of M:m=1:5, and it is mixed with the raw material obtained in step 1), and the mixture is fully ground at room temperature for 2 hours to obtain a mixed powder;

[0039] 3) Place the mixed powder obtained in step 2 in Al 2 o 3 Al in the crucible 2 o 3 cover covered.

[0040] 4) Al 2 o 3 Place the crucible in the furnace, start from room temperature, raise the temperature to 600°C at a rate of 3°C / min, then raise the temperature to 1150°C at a rate of 5°C / min, cool down to 300°C at a rate of 2°C / min after holding for 3 hours, and then Take it out with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com