Sunlight-driven thermochromic material and preparation method thereof

A technology of thermochromic materials and solar light, which is applied in the field of color-changing materials, can solve the problems of reducing optical properties, increasing device volume, and increasing complexity, and achieves good transparency, expanded application fields, bendability and stretchability. good stretch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

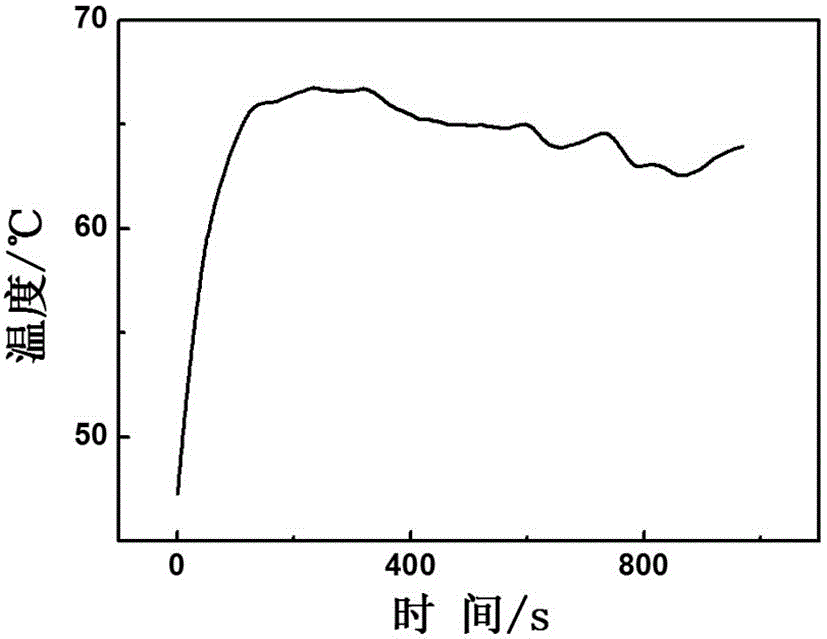

[0024] This embodiment provides a method for preparing a solar-driven thermochromic material, and the specific steps are as follows:

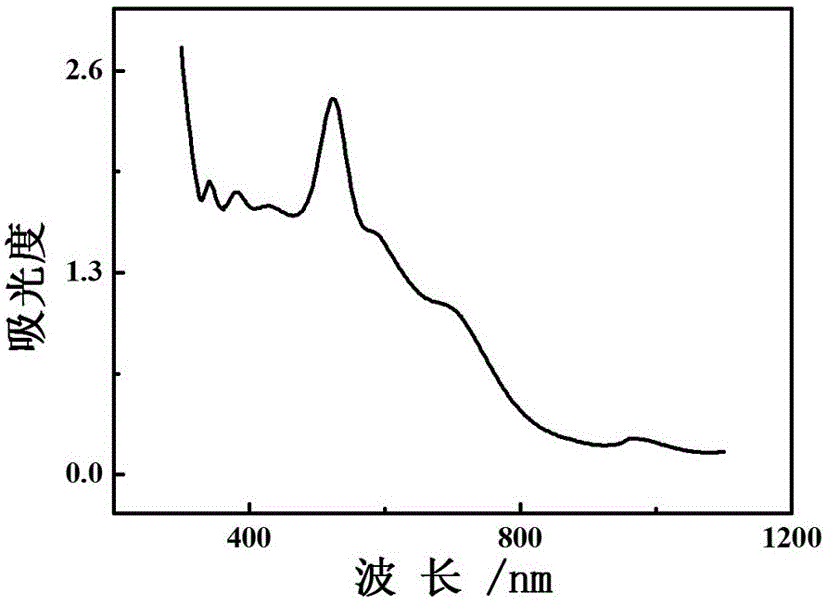

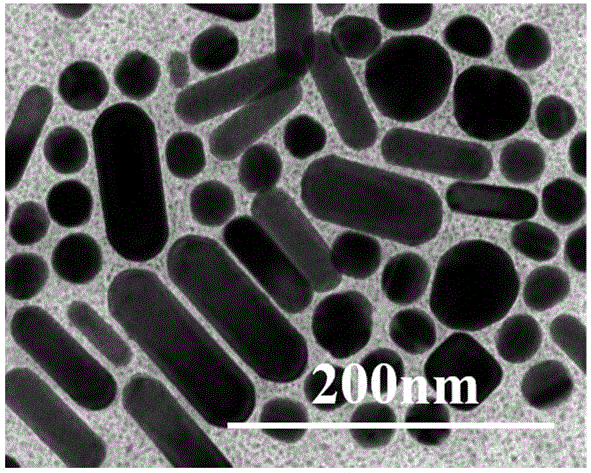

[0025] 1. Use the "seed-growth solution" method to synthesize a variety of gold nanoparticles with different resonance wavelengths, such as gold nanorods with different maximum absorption wavelength positions. The synthesis method of gold nanoparticles can be prepared according to the steps provided in the document "Gold nanorods and their plasmonic properties" (Chem. Soc. Rev., 2013, 42, 2679-2724).

[0026] Centrifuge the synthesized gold nanorod system at a suitable speed (such as 6000 rpm) for 15 minutes, suck off the upper layer, disperse the lower precipitate in water, and centrifuge again at a suitable speed (such as 3000 rpm) After 15 minutes, the upper layer liquid was sucked off, and the lower layer precipitate was redispersed in water to obtain the gold nanoparticle system required in this example. Gold nanoparticle systems with dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com