Integrated method for continuous on-line production and injection of viscous oil emulsion particle diverting agent

An emulsion and diverting agent technology, applied in chemical instruments and methods, mixing methods, earthwork drilling, etc., can solve the problems of complex foam construction, short validity period, poor mobility of inorganic particles, etc., and shorten the production time and preparation process. Simple and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

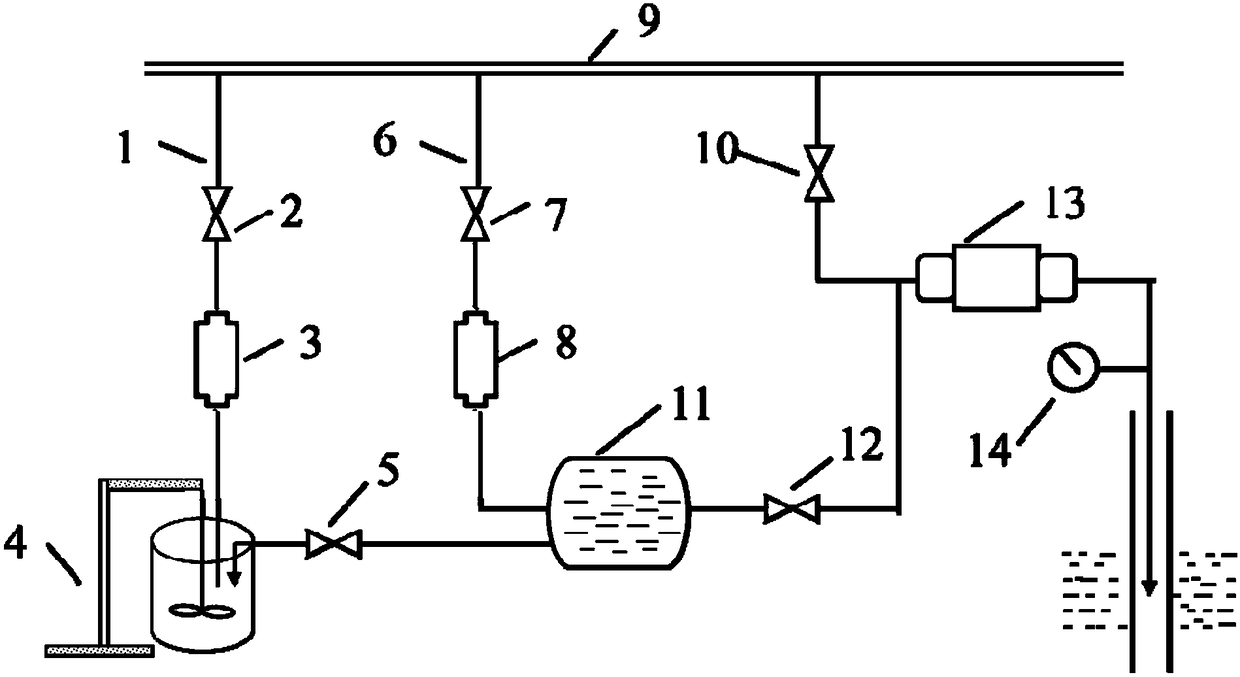

Method used

Image

Examples

Embodiment 1

[0045] Utilize above-mentioned device to carry out the method for continuous on-line production and injection of thick oil emulsion particle diverting agent, comprise the following steps:

[0046] 1. Choose a viscosity of 4×10 5 The heavy oil of mPa·s is added to the mixing tank 4 of the high-speed shearing disperser, and the clean water for mixing is delivered to the mixing tank 4 of the high-speed shearing dispersing machine through the flow meter 3, and the flow meter 3 controls the quality of the heavy oil and the clear water for mixing Ratio 1:4;

[0047] 2. Add an emulsifier, a phase inversion agent and a stabilizer in turn to the mixed solution of thick oil and water prepared in step 1, so that the mass fraction of the emulsifier is 0.6%, and the nonylphenol polyoxyethylene ether in the phase inversion agent The massfraction of sodium salicylate is 0.6%, the massfraction of sodium salicylate in the phase inversion agent is 0.3%, and the massfraction of stabilizer is 0....

Embodiment 2

[0052] Utilize above-mentioned device to carry out the method for continuous on-line production and injection of heavy oil emulsion particle diverting agent, comprising the following steps:

[0053] 1. Choose a viscosity of 4×10 5 The heavy oil of mPa·s is added to the mixing tank 4 of the high-speed shearing disperser, and the clean water for mixing is delivered to the mixing tank 4 of the high-speed shearing dispersing machine through the flow meter 3, and the flow meter 3 controls the quality of the heavy oil and the clear water for mixing Ratio 1:4;

[0054] 2. Add an emulsifier, a phase inversion agent and a stabilizer in turn to the mixed solution of thick oil and water prepared in step 1, so that the mass fraction of the emulsifier is 0.4%, and the nonylphenol polyoxyethylene ether in the phase inversion agent The mass fraction is 0.6%, the sodium salicylate mass fraction in the phase inversion agent is 0.3%, and the mass fraction of the stabilizer is 0.2%;

[0055] 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com