Automobile anti-freezing fluid and preparation method thereof

A technology of automobile antifreeze and parts by weight, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of water-cooled engine cooling system blockage and leakage, formula system balance damage, precipitation and other problems, and achieves inhibition of inorganic salt scale. Accumulation, unique raw materials, fully responsive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

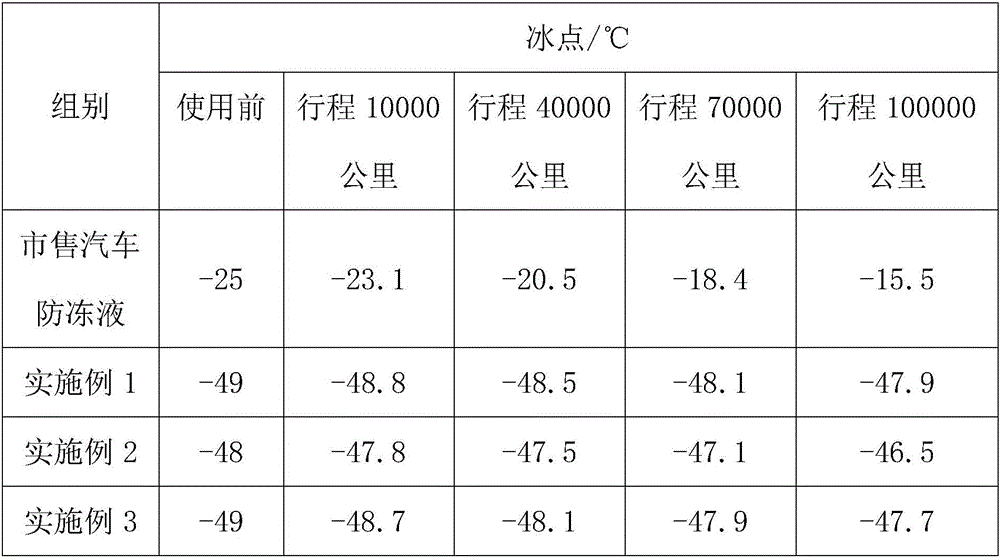

Examples

Embodiment 1

[0017] A kind of automobile antifreeze, is made up of the raw material of following parts by weight:

[0018] 55 parts of 1,3-propanediol, 0.1 part of phytic acid, 1 part of neopentyl glycol diglycidyl ether, 0.2 part of polyvinyl pyrrolidone, 0.5 part of thiocyanic acid, 0.02 part of water-based fluorescent green dye, salicylic acid 1 part of sodium phosphate, 0.1 part of butyl p-hydroxybenzoate, 1 part of lecithin, 2.5 parts of histidine, 1 part of water extract of vine fruit, 2 parts of ethanol extract of camphor tree leaf, 90 parts of water, and the balance is 0.2 %maleic anhydride;

[0019] A kind of automobile antifreeze preparation method, specifically comprises the following steps:

[0020] 1) Add 0.1 part of phytic acid, 0.2 part of polyvinylpyrrolidone, and 0.5 part of thiocyanuric acid to 90 parts of water in turn, mix them, put them in a water bath at a constant 40°C, stir for 20 minutes, and control the speed at 200r / min, filter, discard the precipitate, and ob...

Embodiment 2

[0024] A kind of automobile antifreeze, is made up of the raw material of following parts by weight:

[0025] 75 parts of 1,3-propanediol, 0.3 parts of phytic acid, 2 parts of neopentyl glycol diglycidyl ether, 0.5 parts of polyvinyl pyrrolidone, 1 part of thiocyanic acid, 0.05 parts of water-based fluorescent green dye, salicylic acid 2 parts of sodium phosphate, 0.2 parts of butyl p-hydroxybenzoate, 2 parts of lecithin, 4.5 parts of histidine, 2 parts of water extract of vine fruit, 5 parts of alcohol extract of camphor tree leaves, 125 parts of water, and the balance is 0.2 parts %maleic anhydride;

[0026] A kind of automobile antifreeze preparation method, specifically comprises the following steps:

[0027] 1) Add 0.3 parts of phytic acid, 0.5 parts of polyvinylpyrrolidone, and 1 part of thiocyanuric acid to 125 parts of water in turn, mix them, put them in a water bath at a constant 40°C, stir for 30 minutes, and control the speed at 250r / min, filter, discard the pre...

Embodiment 3

[0031] A kind of automobile antifreeze, is made up of the raw material of following parts by weight:

[0032] 60 parts of 1,3-propanediol, 0.2 parts of phytic acid, 1.5 parts of neopentyl glycol diglycidyl ether, 0.3 parts of polyvinyl pyrrolidone, 0.75 parts of thiocyanic acid, 0.03 parts of water-based fluorescent green dye, salicylic acid 1.5 parts of sodium phosphate, 0.15 parts of butyl p-hydroxybenzoate, 1.5 parts of lecithin, 3.5 parts of histidine, 1.5 parts of water extract of vine fruit, 3.5 parts of ethanol extract of camphor leaves, 115 parts of water, and the balance is 0.2 %maleic anhydride;

[0033] A kind of automobile antifreeze preparation method, specifically comprises the following steps:

[0034] 1) Add 0.2 parts of phytic acid, 0.3 parts of polyvinylpyrrolidone, and 0.75 parts of thiocyanuric acid to 115 parts of water, mix them in turn, put them in a water bath at a constant 40°C, stir for 25 minutes, and control the speed at 300r / min, filter, discard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com