Low-warpage polyester polyketone composite and preparation method thereof

A composite material and low warpage technology, applied in the field of low warpage polyester polyketone composite materials and its production, can solve problems such as performance gaps, achieve high glow wire performance, simple production process, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

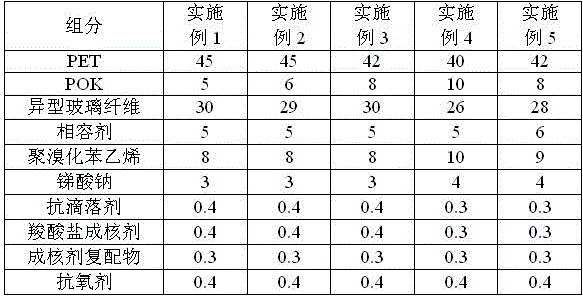

[0014] First, dry polyethylene terephthalate (PET) at 130°C for 6 hours and pour it into a weight loss scale. Next, dry the aliphatic polyketone at 100°C for 6 hours, pour the dried aliphatic polyketone and other additives into a high-speed mixer, stir at a low speed, mix well, pour it into a weight loss scale, and then pass it through a twin-screw extruder Mix and extrude. Shaped glass fibers are forced into Zone 7 via side feed. The blending temperature is 265-280°C, the screw speed is 350r / min, and the product is extruded, water-cooled, and pelletized. The produced material was dried at 130°C for 4 hours, and then standard mechanical property test specimens were prepared on an injection molding machine. The injection pressure is 60-90Mpa, the barrel temperature is 245-260°C, the mold temperature is 80°C, and the injection cycle is 40s. The raw material ratio (mass percentage) of specific embodiment 1-5 is shown in Table 1:

[0015] Table I

[0016]

[0017] The mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com