Gradient electrode for flow batteries and application thereof

A flow battery and electrode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of limited improvement in voltage efficiency and energy efficiency, achieve volume and cost reduction, easy batch preparation, and reduce electrochemical electrodes. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

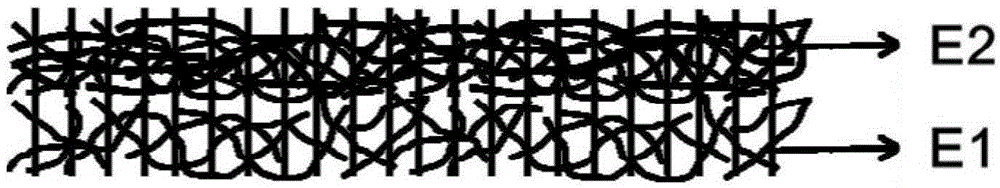

Embodiment 1

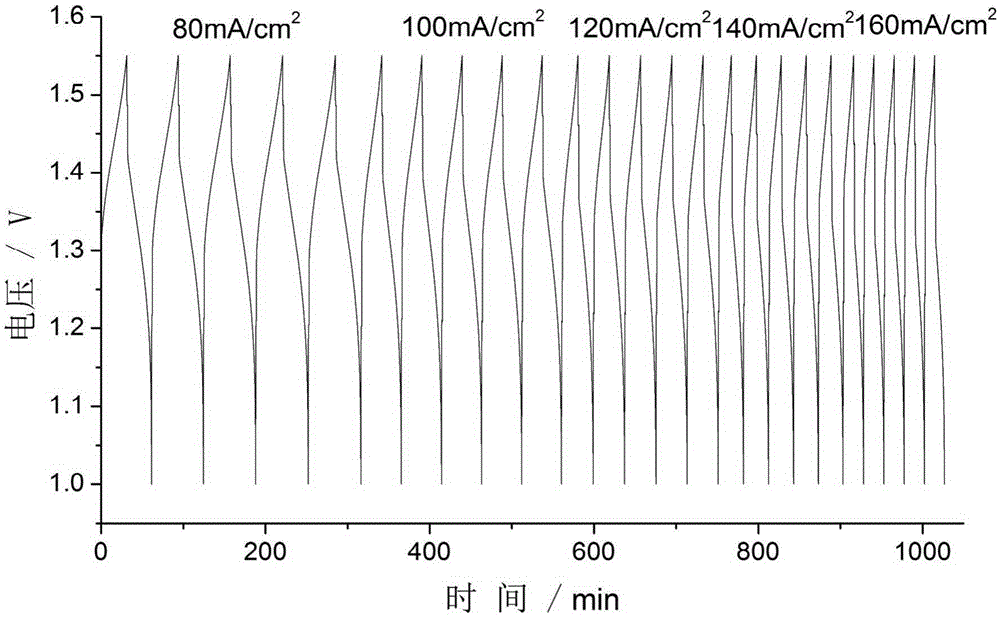

[0028] Choose a thickness of 2.5mm and a bulk density of 0.08gcm -3 The graphite fiber felt is used as the diffusion layer, with a thickness of 2mm and a bulk density of 0.16gcm -3 The carbon fiber felt is used as the catalytic layer, and then the two layers of felt are stacked together, and they are needled into one body with a needle punching machine to make gradient electrodes with different densities in the longitudinal direction, and the needle punching density is 100 needles / cm 2 . When the cell is assembled, the gradient electrode has a diffusion layer close to the bipolar plate and a catalytic layer close to the membrane. Under the compression of the end plate, it is assembled into an all-vanadium flow cell. After compression, the thickness of the electrode is about 3mm, and the electrode area is 48cm 2 . The positive electrolyte is 1.5M VO 2+ 3M H 2 SO 4 Solution 60ml, negative electrode electrolyte is 1.5M V 3+ 3M H 2 SO 4 Solution 60ml. The charge and disc...

Embodiment 2

[0030] Choose a thickness of 4mm and a density of 0.1gcm -3 The carbon fiber felt is used as the diffusion layer, with a thickness of 1mm and a bulk density of 0.2gcm -3 The carbon fiber felt is used as the catalytic layer, and then the two layers of felt are stacked together, and they are needled into one body with a needle punching machine to make gradient electrodes with different densities in the longitudinal direction, and the needle punching density is 200 needles / cm 2 . When the cell is assembled, the gradient electrode has a diffusion layer close to the bipolar plate and a catalytic layer close to the membrane. Under the compression of the end plate, it is assembled into an all-vanadium flow cell. After compression, the thickness of the electrode is about 4mm, and the electrode area is 48cm 2 . The positive electrolyte is 1.5M VO 2+ 3M H 2 SO 4 Solution 60ml, negative electrode electrolyte is 1.5M V 3+ 3M H 2 SO 4 Solution 60ml. The single cell adopting the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com