Resin compositionc and application thereof

A technology of resin composition and mixture, which is applied in the field of copper clad laminates, can solve the problems of cracks and non-flame retardant function of the insulating layer, and achieve the effects of high filling amount, excellent flexibility and excellent insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5 and comparative example 1~3

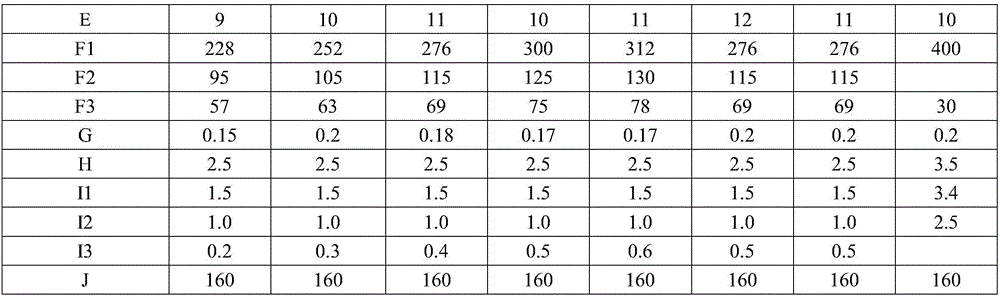

[0048] Each component used in the epoxy resin composition of embodiment 1~5 and comparative example 1~3 and content (by weight) are as shown in table 1; Each component code and its corresponding component name are as follows Shown:

[0049] (A) bismaleimide modified epoxy resin:

[0050] (A1) Bisphenol A epoxy resin, diallyl bisphenol A, 4,4' diphenylmethane bismaleimide, phosphorus compound prepolymer;

[0051](A2) Bisphenol F epoxy resin, diallyl bisphenol S, 4,4' diphenylmethane bismaleimide, phosphorus compound prepolymer;

[0052] (A3) Bisphenol A novolak epoxy resin, diallyl bisphenol A, 4,4' diphenyl ether bismaleimide, phosphorus compound prepolymer.

[0053] (B) Flexible modified epoxy resin:

[0054] (B1) Silicone modified epoxy resin

[0055] (B2) Dimer acid modified flexible epoxy resin

[0056] (C) polyvinyl butyral;

[0057] (C1) Number average molecular weight 15000

[0058] (C2) Number average molecular weight 25000

[0059] (C3) Number average molecula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com