Method for preparing polycarboxylate superplasticizer

A technology of water reducer and polycarboxylate, which is applied in the field of preparation of polycarboxylate water reducer, can solve problems such as inconvenience, achieve the effects of reducing production cost, simplifying process and production equipment, and eliminating the discharge of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

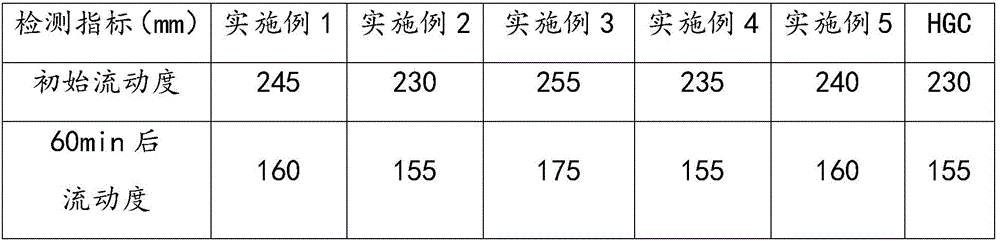

Examples

preparation example Construction

[0024] The main steps of the preparation method of polycarboxylate water reducer of the present invention are:

[0025] Firstly, isopentenol polyoxyethylene ether is dissolved in tap water to form a polyether solution with a mass concentration of 40-55%. Prenyl alcohol polyoxyethylene ether with a molecular weight of 2000-3000 is suitable for use in the present invention.

[0026] Next, add coagent, stir evenly and then add oxidant. Among them, the coagent used in the present invention is preferably methacrylic acid, and the mass ratio of the added amount to prenol polyoxyethylene ether is 1-5%. In the self-made active auxiliary agent of the present invention. The oxidant can be hydrogen peroxide, ammonium persulfate, sodium persulfate or a mixture of several, and the amount of oxidant added accounts for 1-3% of the mass of prenol polyoxyethylene ether.

[0027] Again, a mixed aqueous solution of an aqueous acrylic acid solution, a chain transfer agent, and a reducing agent...

Embodiment 1

[0033] Add 271kg of common tap water to the reactor, and then add 250kg of prenol polyoxyethylene ether (TPEG) with a molecular weight of 2400 under stirring, and add 12.5kg of coagent methacrylic acid after it is completely dissolved. After stirring evenly, add 7.4kg of 28% hydrogen peroxide, and after stirring for 10 minutes, measure the temperature of the bottom material to be 3°C, and start to add dropwise the aqueous solution prepared by 40.2kg of acrylic acid and 80kg of tap water. The mixing solution was added dropwise for 3 hours and 3.5 hours respectively. After the dropwise addition was completed, the temperature was kept for 1 hour. After the reaction was completed, the pH value of the product was adjusted to 7 with 32% sodium hydroxide solution, and the obtained product was ultra-low temperature Polycarboxylate superplasticizer produced from tap water.

Embodiment 2

[0035] Add 820Kg of ordinary tap water into the reaction kettle, and then add 550kg of prenol polyoxyethylene ether with a molecular weight of 2000 under stirring, and add 16kg of methacrylic acid after it is completely dissolved. After stirring evenly, add 8.25kg of 28% hydrogen peroxide, and after stirring for 10 minutes, measure the temperature of the bottom material to be 10°C, and start to add dropwise the aqueous solution prepared by 89.5kg of acrylic acid and 175kg of tap water. The mixing solution was added dropwise for 3 hours and 3.5 hours respectively. After the dropwise addition was completed, the temperature was kept for 1 hour. After the reaction was completed, the pH value of the product was adjusted to 6 with 32% sodium hydroxide solution, and the obtained product was low temperature Polycarboxylate superplasticizer produced from tap water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com