Method for preparing high-purity marine polyunsaturated fatty acid phospholipids from cod viscera

A fatty acid phospholipid, high-purity technology, applied in the directions of edible phospholipid composition, chemical instrument and method, application, etc., can solve the problems that the filler is not easy to reuse, affect the quality of phospholipid, and high operating costs, achieve wide and cheap raw material sources, and reduce extraction. Cost, high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

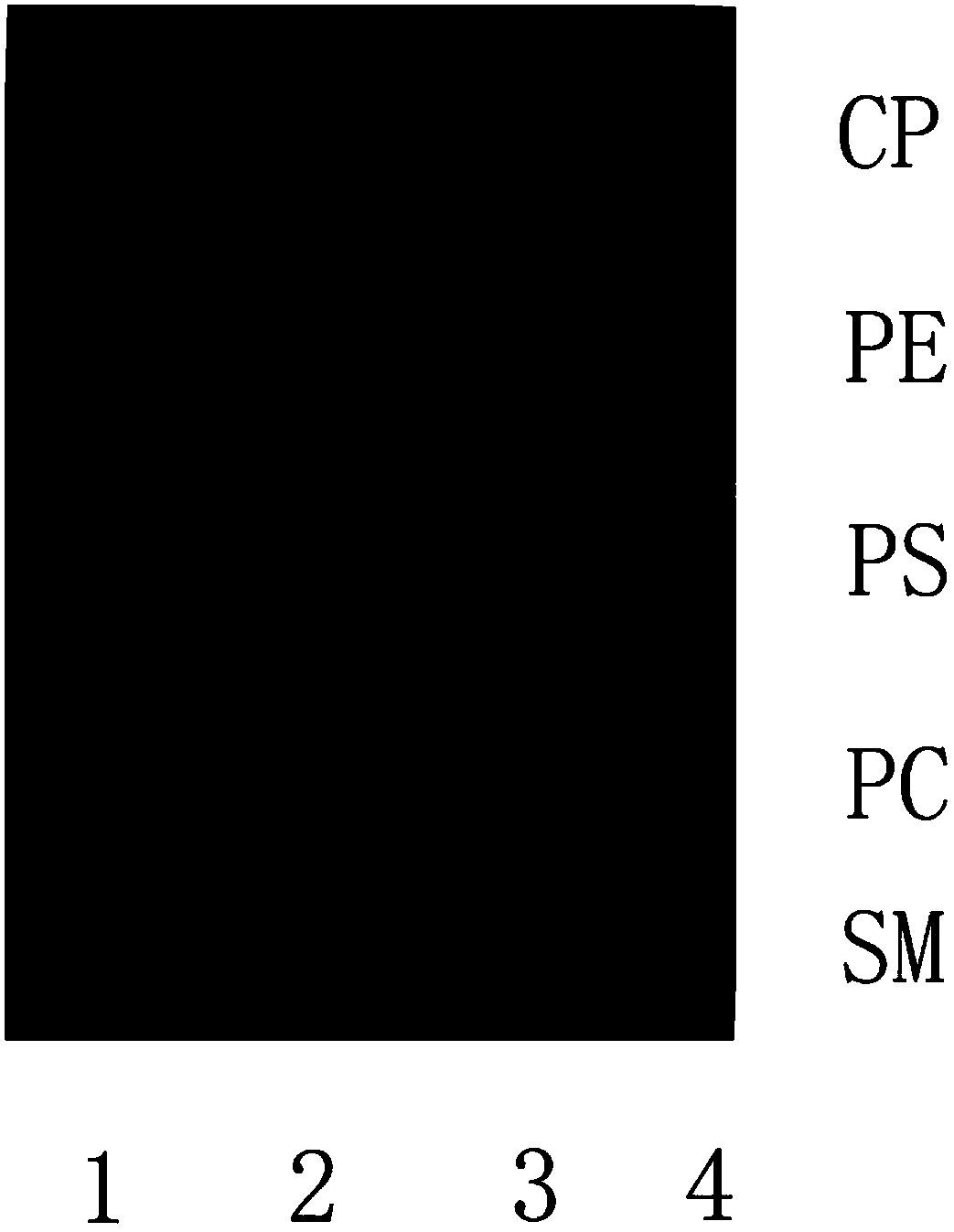

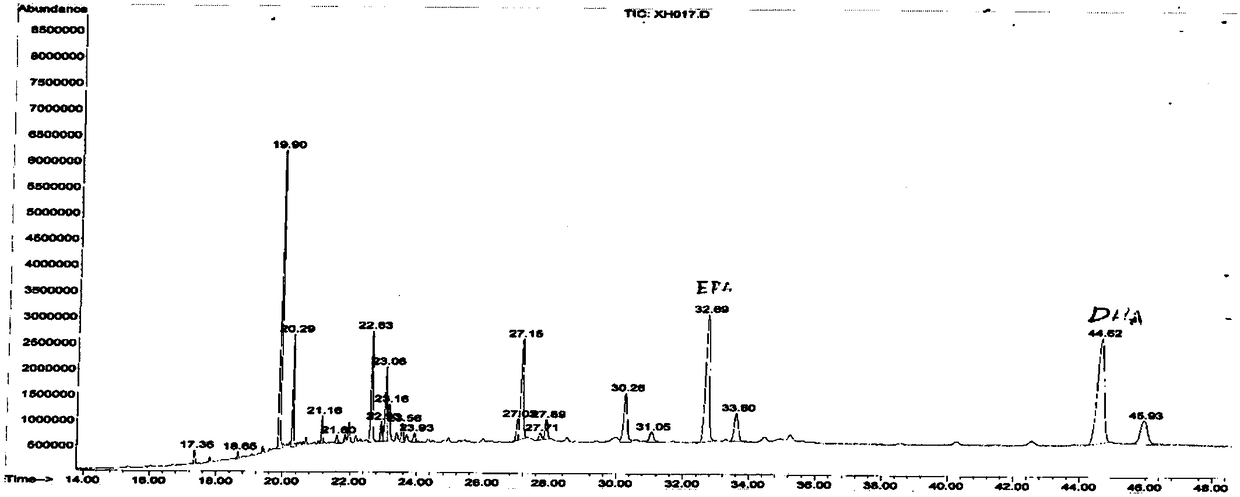

Embodiment 1

[0034] Weigh 100g of frozen cod viscera, crush it with a tissue grinder, add 1000mL of 90% ethanol solution (sodium acetate to make the pH 9.0), stir and extract at room temperature for 2 hours, and filter under reduced pressure to obtain the extract; add the same alkaline The ethanol solution was repeatedly stirred and extracted once, and the extract was obtained by suction filtration. The two extracts were combined, and the pH was adjusted to neutrality with hydrochloric acid; 1:10), stirred for 30 minutes, left to stand and then centrifuged for 10 minutes, the supernatant was concentrated under reduced pressure at 47°C to remove the solvent to obtain crude phospholipids; after the crude phospholipids were dissolved with a small amount of absolute ethanol, the active The white clay is dispersed, the solvent is evaporated, put into the extraction kettle, and the supercritical CO 2 The total phospholipids were obtained by extraction, and the extraction conditions were as follo...

Embodiment 2

[0037] Weigh 100g of frozen cod viscera, grind it with a tissue grinder, add 600mL of 95% ethanol solution (sodium bicarbonate adjusts its pH to 10.0), stir and extract at room temperature for 4 hours, and filter under reduced pressure to obtain the extract; add the same alkaline The ethanol solution was repeatedly stirred and extracted 2 times, each time for 4 hours, and the extract was obtained by suction filtration, the extract was combined, and the pH was adjusted to neutral with hydrochloric acid; 36g of inclusion purifier (beta-cyclodextrin in the purifier) was added to the extract. The weight ratio with activated carbon is 1:10), stirred for 30min, centrifuged for 10min after standing still, took the supernatant and concentrated under reduced pressure at 45°C to remove the solvent to obtain crude phospholipids; after the crude phospholipids were dissolved with a small amount of absolute ethanol, the The activated clay with twice the weight of crude phospholipids is dis...

Embodiment 3

[0039] Weigh 100g of frozen cod viscera, crush it with a tissue grinder, add 1200mL of alkaline ethanol (sodium bicarbonate to adjust its pH to 10.0), stir and extract at room temperature for 4 hours, and filter under reduced pressure to obtain the extract; add the same alkaline The ethanol is repeatedly stirred and extracted once, and the extract is obtained by suction filtration, the extract is combined, and the pH is adjusted to neutrality with hydrochloric acid; 72g of inclusion purifier is added to the extract (the weight ratio of β-cyclodextrin to activated carbon in the purifier is 1 :10), stirred for 40min, centrifuged for 10min, got the supernatant and concentrated under reduced pressure at 43°C to remove the solvent, and obtained the crude phospholipid; The dry solvent is put into the extraction kettle, and the supercritical CO 2 The total phospholipids were obtained by extraction, and the extraction conditions were as follows: the extraction pressure was 22MPa, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com