A kind of preparation method and application of bis-Schiff base-based fluorescent sensing material

A fluorescent sensing and bi-Schiff base technology, applied in the field of chemical fluorescent sensing materials, can solve problems such as changes in cell membrane permeability and cell membrane dysfunction, and achieve the effects of shortening the reaction time, enhancing water solubility, and stabilizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

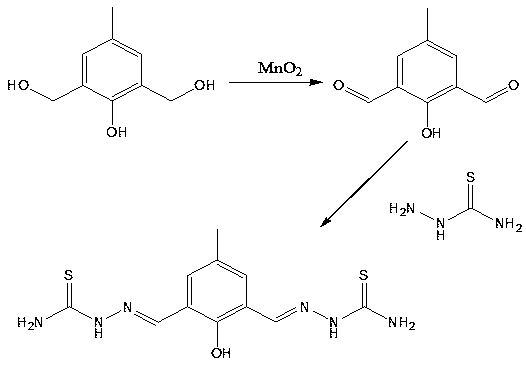

[0037] Step 1. Preparation of 2,6-diacetaldehyde-4-methylphenol: Put 1g of 2,6-dimethylol-p-methylphenol in a round-bottomed flask, dissolve it in 20 mL of acetonitrile, 65°C oil After stirring in the bath for 30 minutes, add 6 g of active manganese dioxide, stir and reflux at 110 ° C for 65 hours, cool to room temperature after the reaction, filter to remove the oxidant manganese dioxide, collect the filtrate, and remove the solvent by rotary evaporation under reduced pressure to obtain a crude product. Purified by recrystallization in ethanol to obtain a pale yellow solid.

[0038] Step 2. Preparation of fluorescent sensing materials based on bis-Schiff bases: 0.164g of 2,6-diacetaldehyde-4-methylphenol and 0.182g of thiosemicarbazide were placed in a round bottom flask, and 20mL of anhydrous Dissolve it in ethanol, and add 2 drops of glacial acetic acid as a catalyst. Stir and reflux in an oil bath at 65°C for 5 h, cool to room temperature after the reaction, and remove th...

Embodiment 2

[0040] Step 1. Preparation of 2,6-diacetaldehyde-4-methylphenol: Put 3g of 2,6-dimethylol-p-methylphenol in a round-bottomed flask, dissolve it in 40 mL of acetonitrile, 65°C oil After stirring in the bath for 30 minutes, add 18 g of active manganese dioxide, stir and reflux at 130 ° C for 80 hours, cool to room temperature after the reaction, filter to remove the oxidant manganese dioxide, collect the filtrate, and remove the solvent by rotary evaporation under reduced pressure to obtain a crude product. Purified by recrystallization in ethanol to obtain a pale yellow solid.

[0041] Step 2. Preparation of fluorescent sensing materials based on bis-Schiff bases: 0.492g of 2,6-diacetaldehyde-4-methylphenol and 0.546g of thiosemicarbazide were placed in a round-bottomed flask, and 40mL of anhydrous Dissolve it in ethanol, and add 2 drops of glacial acetic acid as a catalyst. Stir and reflux in an oil bath at 75°C for 7 hours, cool to room temperature after the reaction, and re...

Embodiment 3

[0043] Step 1. Preparation of 2,6-diacetaldehyde-4-methylphenol: Put 2g of 2,6-dimethylol-p-methylphenol in a round-bottomed flask, dissolve it in 30 mL of acetonitrile, 65°C oil After stirring in the bath for 30 minutes, add 12 g of active manganese dioxide, stir and reflux at 120 ° C for 72 hours, cool to room temperature after the reaction, filter to remove the oxidant manganese dioxide, collect the filtrate, and remove the solvent by rotary evaporation under reduced pressure to obtain a crude product. Purified by recrystallization in ethanol to obtain a pale yellow solid.

[0044] Step 2. Preparation of fluorescent sensing materials based on bis-Schiff bases: 0.328g of 2,6-diacetaldehyde-4-methylphenol and 0.364g of thiosemicarbazide were placed in a round-bottomed flask, and 30mL of anhydrous Dissolve it in ethanol, and add 2 drops of glacial acetic acid as a catalyst. Stir and reflux in an oil bath at 70°C for 6 hours, cool to room temperature after the reaction is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com