Microbial flocculating agent generated by paenibacillus and applications thereof

A microbial flocculant and Paenibacillus technology, applied in the field of microbial flocculants, can solve the problems of restricting the production and application of microbial flocculants, large dosage of polyaluminum chloride, and high cost, so as to improve the flocculation effect and settling speed quickly. , the effect of flocs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Screening, isolation and identification of Paenibacillus sp.LX03.

[0027] (1) Screening and isolation of strains

[0028] Soil samples collected from Yancheng City, Jiangsu Province were dissolved in distilled water, and after 1 hour, the supernatant was diluted with 10 2 ~10 6 times, prepare Htm solid medium, spread 100 μL of the previously diluted samples respectively, place them in a biochemical incubator, and incubate at 30°C for 2-3 days. Select the strains with obvious differences in the characteristics of the colonies on the petri dish, and use the dilution coating method to purify until a single strain is obtained, and its colony morphology is as follows: figure 1 shown.

[0029] The composition of Htm liquid medium is as follows: starch 20g / L, sodium dihydrogen phosphate 1g / L, potassium nitrate 3g / L, calcium chloride 0.07g / L, magnesium chloride 0.2g / L, ferrous sulfate heptahydrate 0.0125g / L , manganese sulfate 0.003g / L, zinc chloride 0.0075g / L, the solvent...

Embodiment 2

[0033] Preparation process of microbial flocculant produced by Paenibacillus sp.LX03 strain

[0034] Paenibacillus sp.LX03 was inoculated into the fermentation medium, the culture temperature was 30°C, and the shaker was cultivated at 250rpm for 2 to 3 days to obtain the fermentation broth containing the microbial flocculant. After removing the bacteria by centrifugation at 7000rpm for 10min, Add 2 to 3 times the volume of ethanol to precipitate extracellular products, and then add distilled water to dissolve the extracellular products after drying to obtain the microbial flocculant. The fermentation medium is the above-mentioned Htm liquid medium.

Embodiment 3

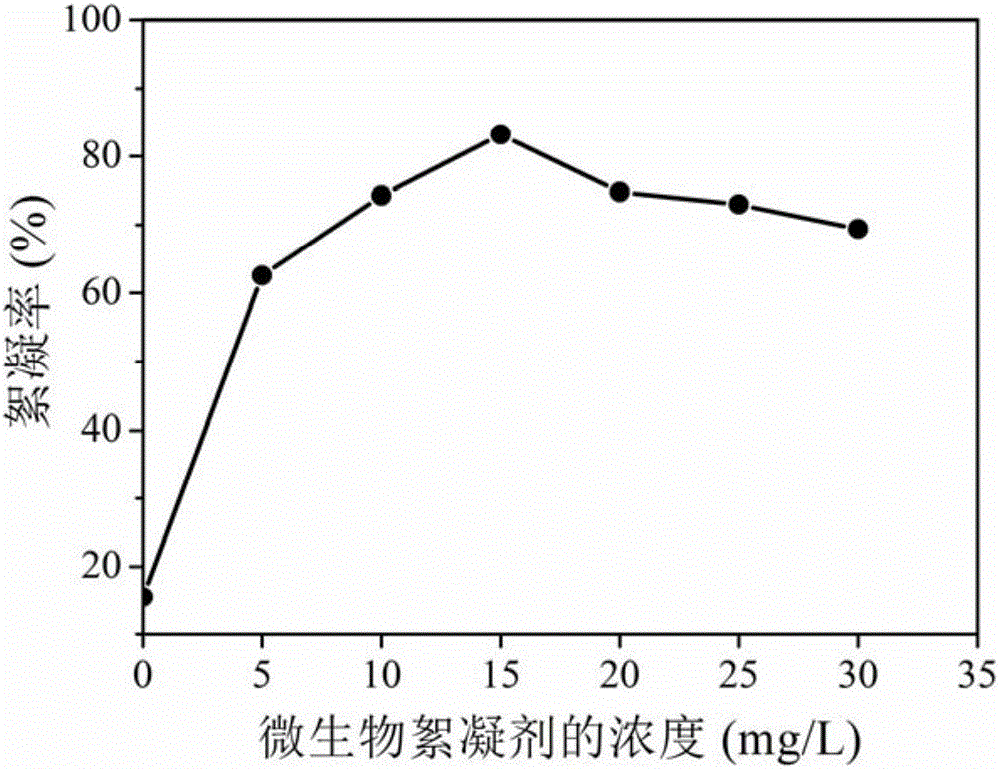

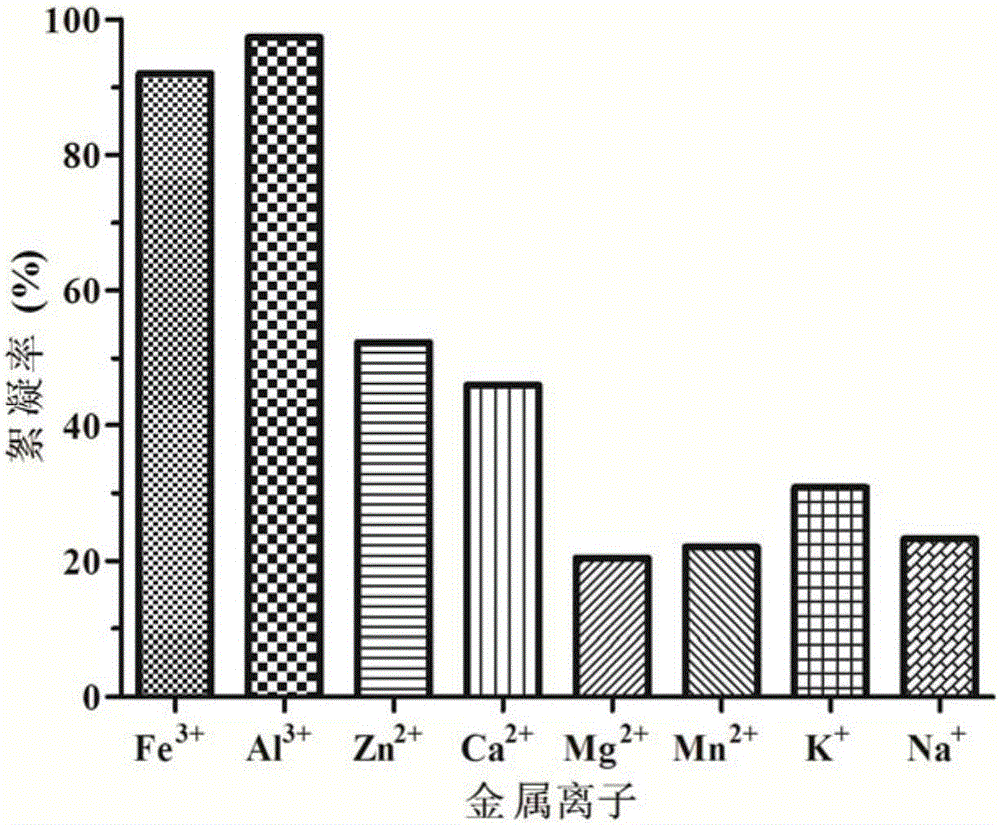

[0036] Study on the flocculation performance of microbial flocculant produced by Paenibacillus sp.LX03 strain.

[0037] Prepare kaolin suspension (4g / L) as simulated wastewater to test the flocculation performance of microbial flocculants. The specific method is: put 50mL of kaolin suspension (4g / L) in a 50mL beaker, add a certain amount of microbial flocculant, stir with a magnetic force at 100rpm at room temperature for 1min, and after standing still for 5min, take a liquid sample at the middle height and measure it in the spectrophotometer. Measure its absorbance at a wavelength of 550nm, and use distilled water instead of microbial flocculant as a control group.

[0038] The formula for calculating the flocculation rate is:

[0039] Flocculation rate=(A﹣B) / A×100%

[0040] Among them, A is the absorbance of the control group at 550nm, and B is the absorbance of the experimental group at 550nm.

[0041] (1) Flocculation characteristics of microbial flocculants

[0042] C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com