Composite material of heat insulation and sound insulation aerogel layer composite breathable membrane and manufacturing method thereof

A composite material and manufacturing method technology, applied in chemical instruments and methods, lamination, coating, etc., can solve the problems of lack of airgel performance to fully exert, and achieve good heat insulation and sound insulation effects, extensive life, and flexibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

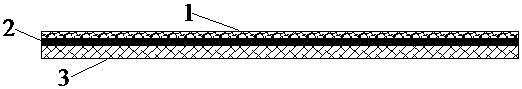

[0028] Example 1: See figure 1

[0029] A composite material of a heat-insulating and sound-insulating airgel layer composite breathable membrane, comprising: an expanded polytetrafluoroethylene film layer 1, an adhesive connection layer 2 and a silica airgel layer 3, and the expanded polytetrafluoroethylene The vinyl film layer 1 and the silica airgel layer 3 are bonded through an adhesive connection layer 2, and the adhesive connection layer 2 is a flame-retardant polyurethane adhesive.

[0030] The manufacturing method of the composite material of the heat-insulating and sound-insulating airgel layer composite breathable film specifically comprises the following steps:

[0031] Process preparation, expanded polytetrafluoroethylene film unwinding, rolling coating flame-retardant polyurethane adhesive on expanded polytetrafluoroethylene film, laying airgel, spraying flame-retardant polyurethane adhesive on the silica airgel layer, The expanded polytetrafluoroethylene film i...

Embodiment 2

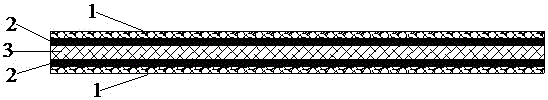

[0032] Example 2: See figure 2

[0033] A composite material of a heat-insulating and sound-insulating airgel layer composite breathable membrane, comprising: an expanded polytetrafluoroethylene film layer 1, an adhesive connection layer 2 and a silica airgel layer 3, and the expanded polytetrafluoroethylene The vinyl film layer 1 and the silica airgel layer 3 are bonded through an adhesive connection layer 2, and the adhesive connection layer 2 is a flame-retardant polyurethane adhesive.

[0034] The manufacturing method of the composite material of the heat-insulating and sound-insulating airgel layer composite breathable film specifically comprises the following steps:

[0035] Process preparation, expanded polytetrafluoroethylene film unwinding, rolling coating flame-retardant polyurethane adhesive on expanded polytetrafluoroethylene film, laying silica airgel, spraying flame-retardant adhesive on the silica airgel layer Polyurethane adhesive, covering the expanded poly...

Embodiment 3

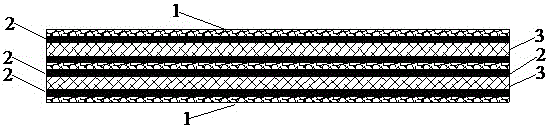

[0036] Example 3: See image 3

[0037] A composite material of a heat-insulating and sound-insulating airgel layer composite breathable membrane, comprising: an expanded polytetrafluoroethylene film layer 1, an adhesive connection layer 2 and a silica airgel layer 3, and the expanded polytetrafluoroethylene The vinyl film layer 1 and the silica airgel layer 3 are bonded through an adhesive connection layer 2, and the adhesive connection layer 2 is a coating containing airgel.

[0038] The manufacturing method of the composite material of the heat-insulating and sound-insulating airgel layer composite breathable film specifically comprises the following steps:

[0039]Process preparation, expanded polytetrafluoroethylene film unwinding, rolling coating containing airgel on the expanded polytetrafluoroethylene film, laying silica airgel layer, spraying coating containing For airgel coating, the expanded polytetrafluoroethylene film is covered on the silica airgel layer, heate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com