A preparation method of moisture-conducting and quick-drying micro-nano regenerated fiber non-woven fabric

A technology of regenerated fiber, moisture-conducting and quick-drying, applied in chemical instruments and methods, manufacturing tools, mechanical equipment, etc., can solve the problems of chemical fiber feel, comfort, low skin-friendly performance, etc., achieve good moisture absorption and moisture release function, improve The effect of improving the utilization rate and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

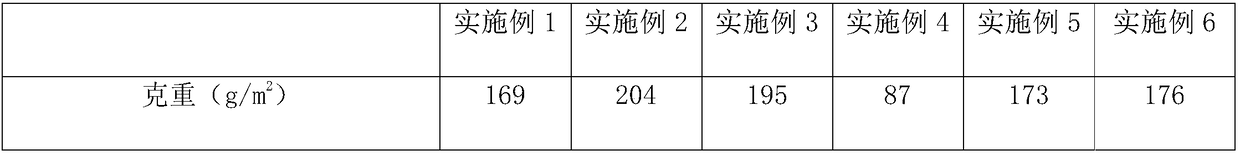

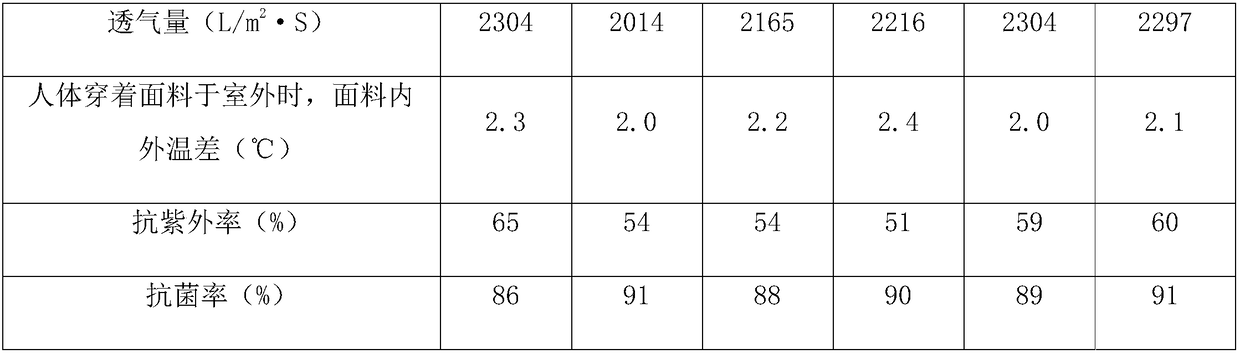

Examples

Embodiment 1

[0027] (1) Take out the branches and tips of the bamboo, cut into bamboo slices with a length of 8 cm, soak the bamboo slices in the degumming solution, cook under heat and pressure, wash with water, separate filaments, reduce, soften, and comb fibers to obtain a diameter of 8 cm. Bamboo long fibers with a length of not less than 2 cm and bamboo short fibers with a length of less than 2 cm.

[0028] (2) Add bamboo short fibers into a cellulase solution with a mass fraction of 1%, stir at a constant temperature of 30° C. for 1 h, wash the product with distilled water, and freeze-dry to obtain bamboo fiber nanowhiskers with a diameter of 3 nm and a length of 20 nm.

[0029] (3) In parts by weight, adding 1 part of bamboo fiber nano whiskers to 30 parts of regenerated silk protein solution with a mass fraction of 6% forms a spinning solution, wherein tussah silk fibroin and mulberry silk in the regenerated silk protein solution The mass ratio of prime is 5:1.

[0030] (4) Evenly...

Embodiment 2

[0033] (1) Take out the branches and tips of the bamboo, cut into bamboo slices with a length of 10cm, soak the bamboo slices in the degumming solution, cook under heat and pressure, wash with water, separate filaments, reduce, soften, and comb fibers to obtain a diameter of 10 cm. Bamboo long fibers with a length of not less than 2 cm and bamboo short fibers with a length of less than 2 cm.

[0034] (2) Add bamboo short fibers into a cellulase solution with a mass fraction of 3%, stir at 40° C. for 3 h, wash the product with distilled water, and freeze-dry to obtain bamboo fiber nanowhiskers with a diameter of 10 nm and a length of 50 nm.

[0035] (3) In parts by weight, add 1 part of bamboo fiber nano whiskers to 40 parts of regenerated silk protein solution with a mass fraction of 8% to form a spinning solution, wherein tussah silk fibroin and mulberry silk in the regenerated silk protein solution The mass ratio of prime is 10:3.

[0036] (4) Evenly disperse the bamboo lon...

Embodiment 3

[0039] (1) Take out the branches and tips of the bamboo, cut into bamboo slices with a length of 9 cm, soak the bamboo slices in the degumming solution, cook under heat and pressure, wash with water, separate filaments, reduce, soften, and comb fibers to obtain a diameter of 9 cm. Bamboo long fibers with a length of not less than 2 cm and bamboo short fibers with a length of less than 2 cm.

[0040] (2) Add bamboo short fibers into a cellulase solution with a mass fraction of 2%, stir at a constant temperature of 35° C. for 2 h, wash the product with distilled water, and freeze-dry to obtain bamboo fiber nanowhiskers with a diameter of 8 nm and a length of 45 nm.

[0041] (3) In parts by weight, add 1 part of bamboo fiber nano whiskers to 35 parts of regenerated silk protein solution with a mass fraction of 7% to form spinning solution, wherein tussah silk fibroin and mulberry silk in the regenerated silk protein solution The mass ratio of prime is 8:1.

[0042] (4) Evenly di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com