Spiral spring production method based on continuous fibers

A technology of continuous fiber and manufacturing method, applied in the field of composite material parts forming, can solve the problems of low spring stiffness coefficient, complex forming process, pollution of equipment cost, etc., and achieve the effect of improving stiffness coefficient, simple forming process and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0032] In order to further illustrate the technical solution of the present invention, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

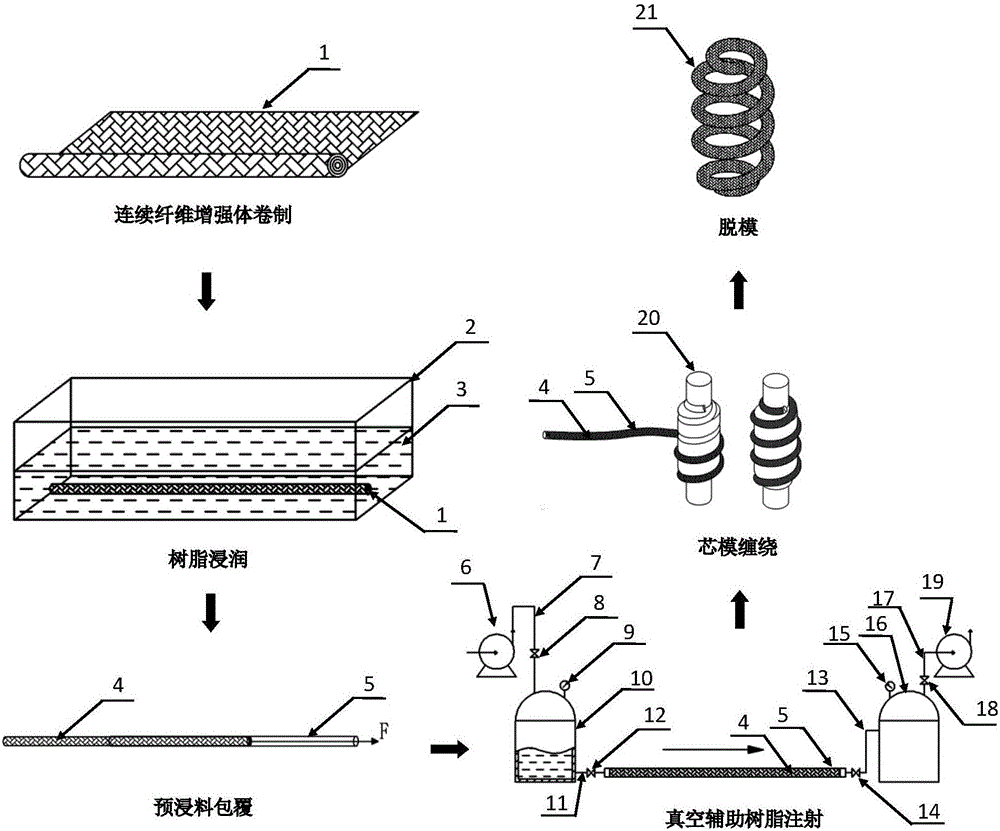

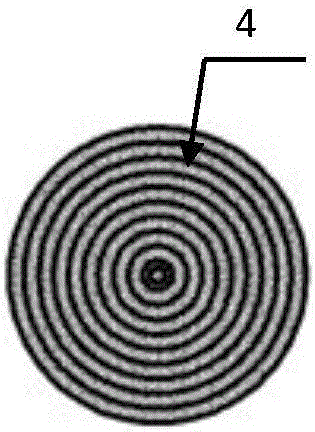

[0033] Such as figure 1 Shown, the present invention discloses a kind of coil spring manufacturing method based on continuous fiber, and concrete process is as follows:

[0034] S1: rolling continuous fiber;

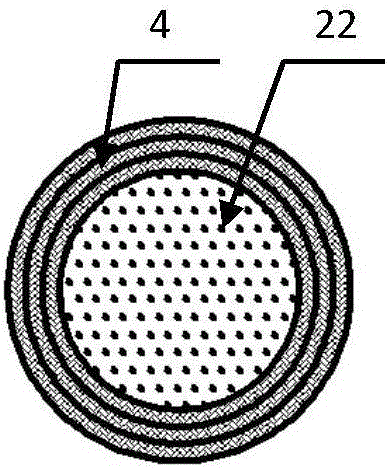

[0035] The continuous fiber is rolled as a reinforcement. In this process, only the continuous fiber 1 can be rolled independently, or the continuous fiber 1 can be rolled into a non-metallic core material 22, a metal core material 23, or a non-metallic / metal hybrid composite core material 24 One of.

[0036] S2: a resin infiltration;

[0037] Put the rolled continuous fiber reinforcement into the prepreg tank 2, and the prepreg tank 2 is filled with the resin prepreg 3 to prepare the fiber resin prepreg 4;

[0038] S3: secondary resin infiltration;

[0039] The fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com